Method and reagent for cleaning and repairing discarded reverse osmosis film in offline mode

A reverse osmosis membrane, off-line technology, applied in the direction of semi-permeable membrane separation, reverse osmosis, chemical instruments and methods, etc., to achieve the effects of enhanced membrane repair rate, high pertinence, and avoiding chemical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

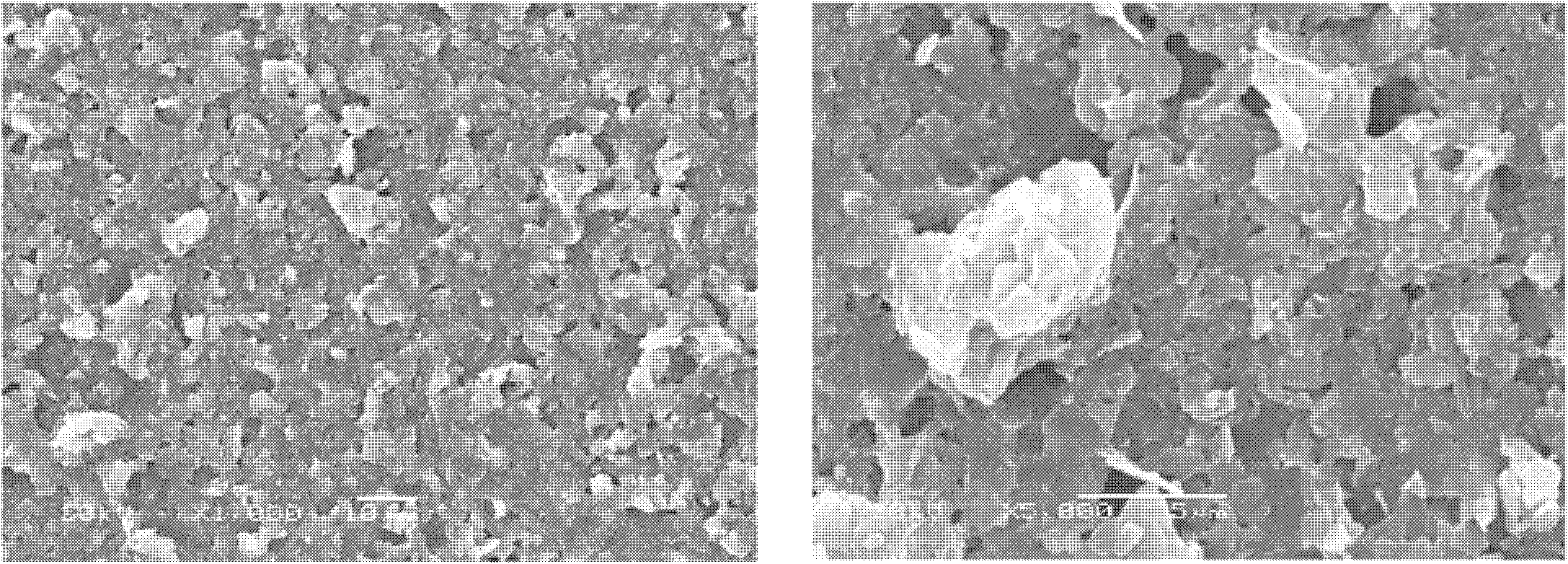

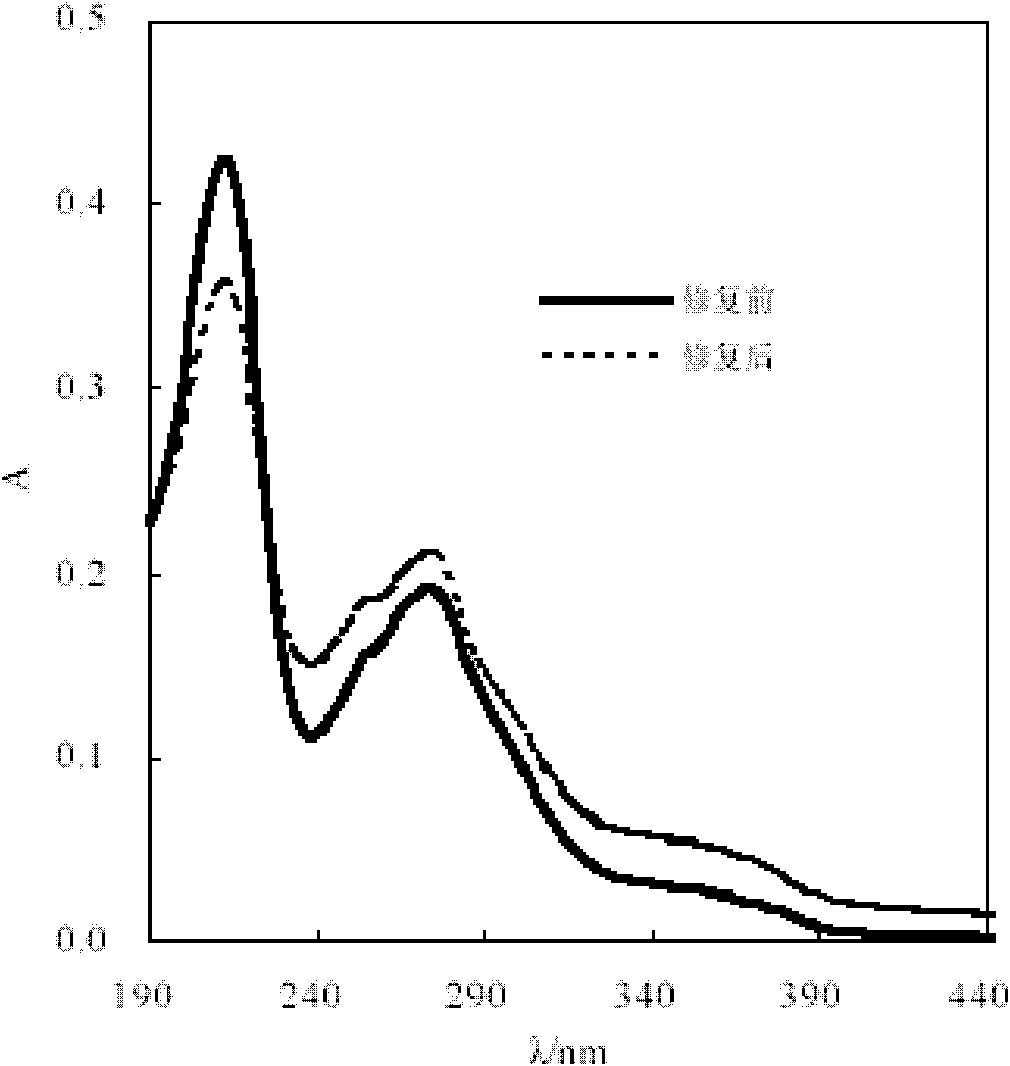

[0055] The No. 25 waste reverse osmosis membrane produced by Nitto Denko Co., Ltd. is CPA3-8080 to analyze the membrane scale components. SEM), x diffractometer to identify the retentate sample, the crystal structure and morphology of membrane scale are as follows figure 1 . Characterize and analyze the scales formed in the waste reverse osmosis membrane, and confirm that the pollution type is silicate and / or carbonate; secondly, analyze and measure the membrane scales of different pollution types by three chemical methods, and obtain the Composition of the membrane scale of the reverse osmosis membrane; finally, when chemical analysis cannot be carried out, use the SDI instrument to test the color and density of the residue on the reverse osmosis membrane to judge the classification of the dirt. The white residue is silicon, sandy clay, and calcium scale ; The shape of the lens is inorganic colloid and calcium scale; finally, the analysis result of the membrane scale compos...

Embodiment 2

[0073] The No. 5 waste reverse osmosis membrane of BW30-400 produced by Dow Chemical Company is analyzed according to the method and steps of embodiment 1 for membrane scale composition analysis, first confirming that the pollution type is silicate and / or carbonate; The membrane scale of different pollution types is analyzed and measured by three chemical analysis methods, and the membrane scale composition of the waste reverse osmosis membrane is obtained; finally, when the chemical analysis cannot be carried out, the residue on the reverse osmosis membrane is tested by the SDI instrument. Color, density, judge the dirt classification, the white residue is silicon, sandy clay, calcium scale; the shape of the lens is calcium scale; finally, the analysis result of the membrane scale composition of the waste reverse osmosis membrane is that the main component of the membrane scale is SiO 2 , also contains illite, mica stone and plagiochlorite, mainly composed of Si, K, Ca, Mg, Al...

Embodiment 3

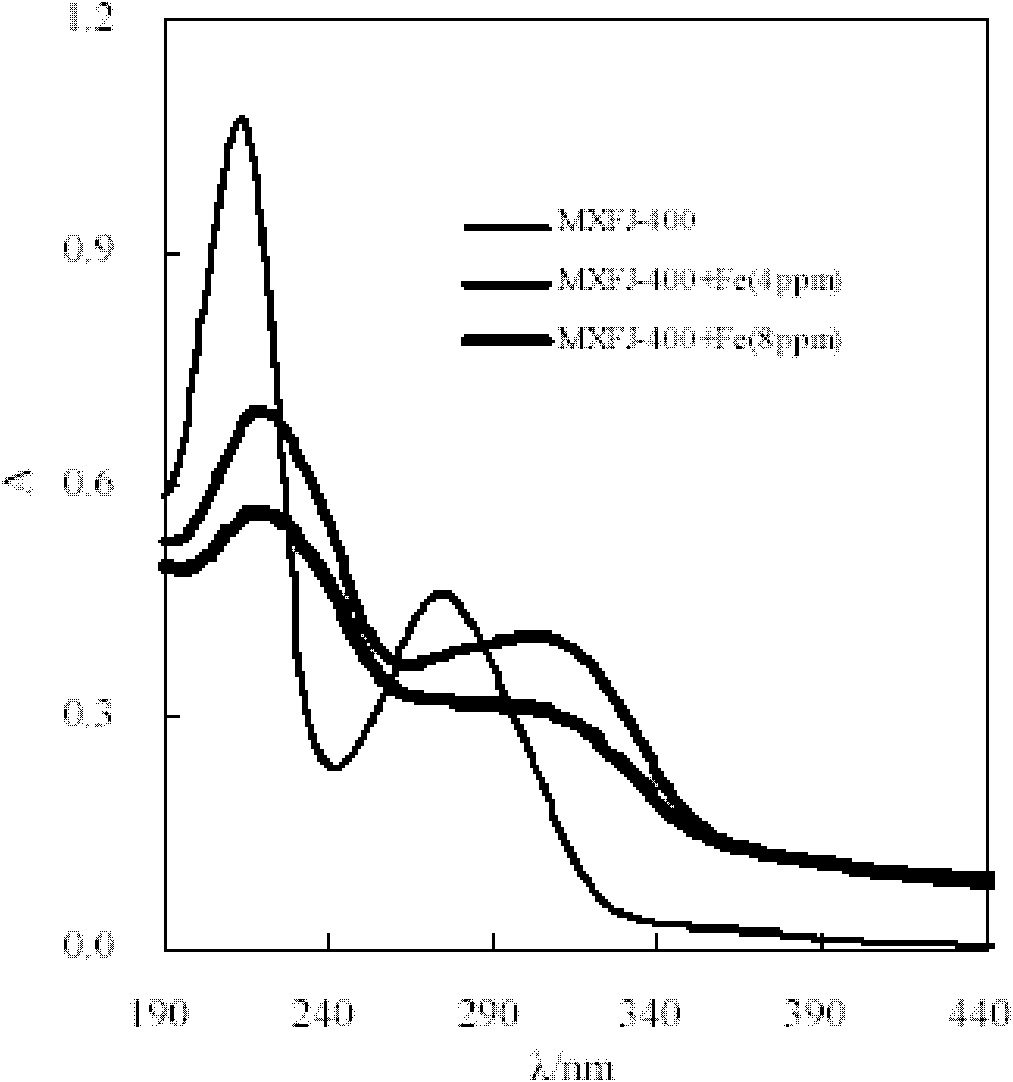

[0085] The No. 6 waste reverse osmosis membrane produced by Nitto Denko Co., Ltd., whose model is CPA3-8080, was analyzed according to the method and steps of Example 1, and the pollution type was confirmed to be silicate, carbonate and / or iron oxide. Second, through the analysis and determination of membrane scales of different pollution types through three chemical analysis methods, the membrane scale composition of waste reverse osmosis membranes can be obtained; finally, when chemical analysis cannot be carried out, use the SDI instrument to test reverse osmosis membranes The color and density of the residue on the surface are used to determine the classification of the dirt. The brown residue is iron dirt; the white residue is silicon, sandy clay, and calcium dirt; the shape of the lens is inorganic colloid and calcium dirt; Judging by the thick state, it also contains biological fouling or organic fouling. Finally, the analysis result of the membrane scale composition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com