Synthesis method of high-purity silicon carbon block

An aluminum-silicon-carbon and block technology is applied in the field of ceramic materials, which can solve the problems of high raw material cost, high price of aluminum-silicon-carbon, and inability to large-scale industrial application, and achieve the effect of low production cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

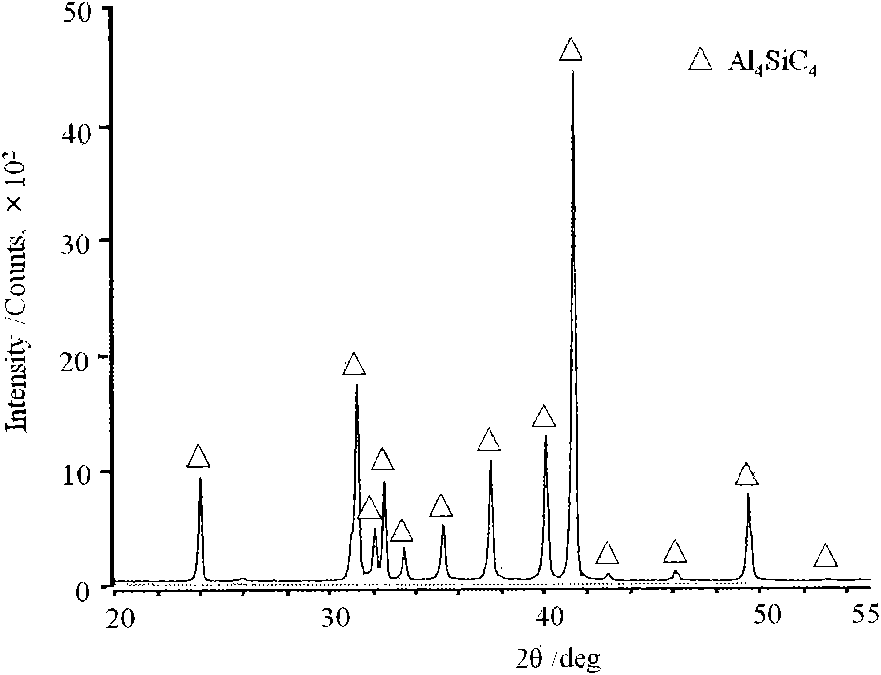

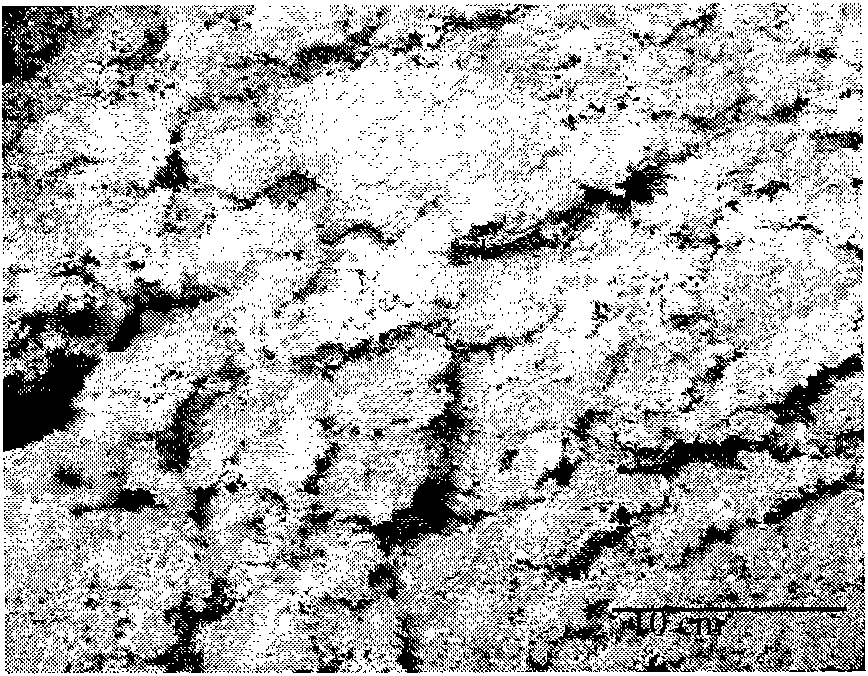

[0022] Embodiment 1, synthetic aluminum silicon carbon block body

[0023] The selected formula is: sintered corundum (average particle size 50mm): quartz sand (average particle size 150mm): petroleum coke (average particle size 20mm): black SiC (average particle size 5mm)=50:16:30:4 (mass ratio), 4 A raw material is assembled into a layer of raw material group according to the formula ratio and the following order from bottom to top: Al 2 o 3 Raw Material-Carbon Raw Material-SiC Raw Material-SiO 2 Raw materials, the thickness of each raw material group is about 300mm, and then the raw material groups are stacked layer by layer until the hearth of the electric arc furnace is filled. Electric heating in the air for 8 hours, the heating temperature is about 3500 ℃. After power-off and cooling, the product is cleaned out from the furnace, and the outer impurity-enriched layer is peeled off to obtain a block-shaped aluminum-silicon-carbon product. After analysis, Al in the syn...

Embodiment 2

[0025] Embodiment 2, synthesizing aluminum-silicon-carbon block

[0026] The selected formula is: sintered corundum (average particle size 5mm): quartz sand (average particle size 5mm): coal coke (average particle size 2mm): green SiC (average particle size 2mm)=49:18:32:1 (mass ratio), 4 A raw material is assembled into a layer of raw material group according to the formula ratio and the following order from bottom to top: Al 2 o 3 Raw Material-Carbon Raw Material-SiC Raw Material-SiO 2 Raw materials, the thickness of each layer of raw material groups is about 200mm, and then the raw material groups are stacked layer by layer until the hearth of the electric arc furnace is full. Heating in the air for 5 hours, the heating temperature is about 3000°C. After power-off and cooling, the product is cleaned out from the furnace, and the outer impurity-enriched layer is peeled off to obtain a block-shaped aluminum-silicon-carbon product. After analysis, Al in the synthesized blo...

Embodiment 3

[0027] Embodiment 3, synthesizing aluminum-silicon-carbon block

[0028] The selected formula is: fused corundum (average particle size 20mm): quartz sand (average particle size 50mm): petroleum coke (average particle size 10mm): black SiC (average particle size 2mm)=53:10:36:1 (mass ratio), the The 4 kinds of raw materials are assembled into a layer of raw material groups according to the formula ratio and the following order from bottom to top: Al 2 o 3 Raw Material-Carbon Raw Material-SiC Raw Material-SiO 2 Raw materials, the thickness of each layer of raw material groups is about 250mm, and then the raw material groups are stacked layer by layer until the hearth of the electric arc furnace is full. Electric heating in air for 6 hours, the heating temperature is about 3200°C. After power-off and cooling, the product is cleaned out from the furnace, and the outer impurity-enriched layer is peeled off to obtain a block-shaped aluminum-silicon-carbon product. After analysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com