Perfume drying device and essential oil recycling method

A drying device and spice technology, applied in the directions of essential oils/spice, fat production, etc., can solve the problems of loss of essential oil components, large heating, energy consumption, etc., and achieve the effects of reducing energy consumption, reducing energy consumption, and accelerating drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

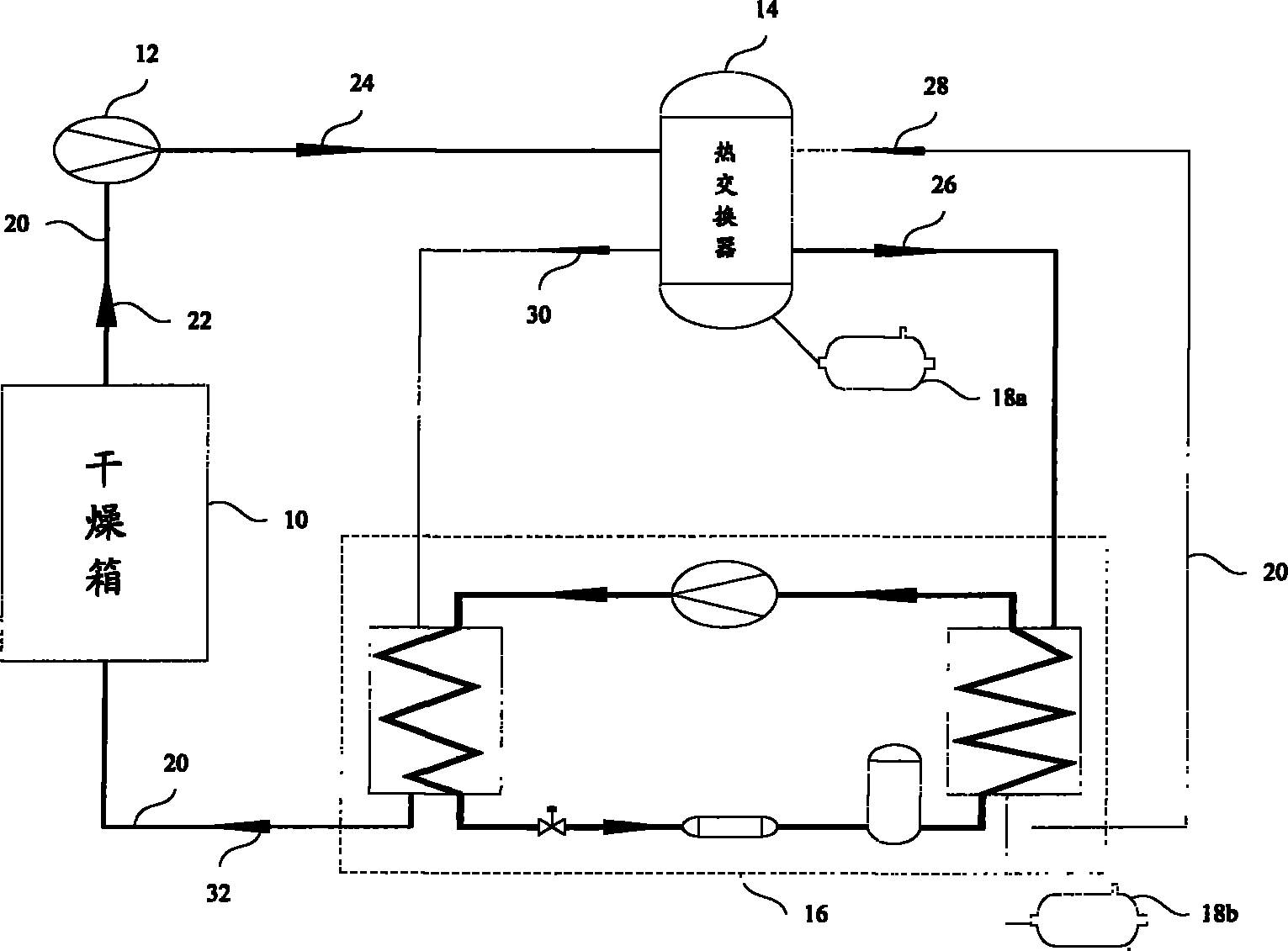

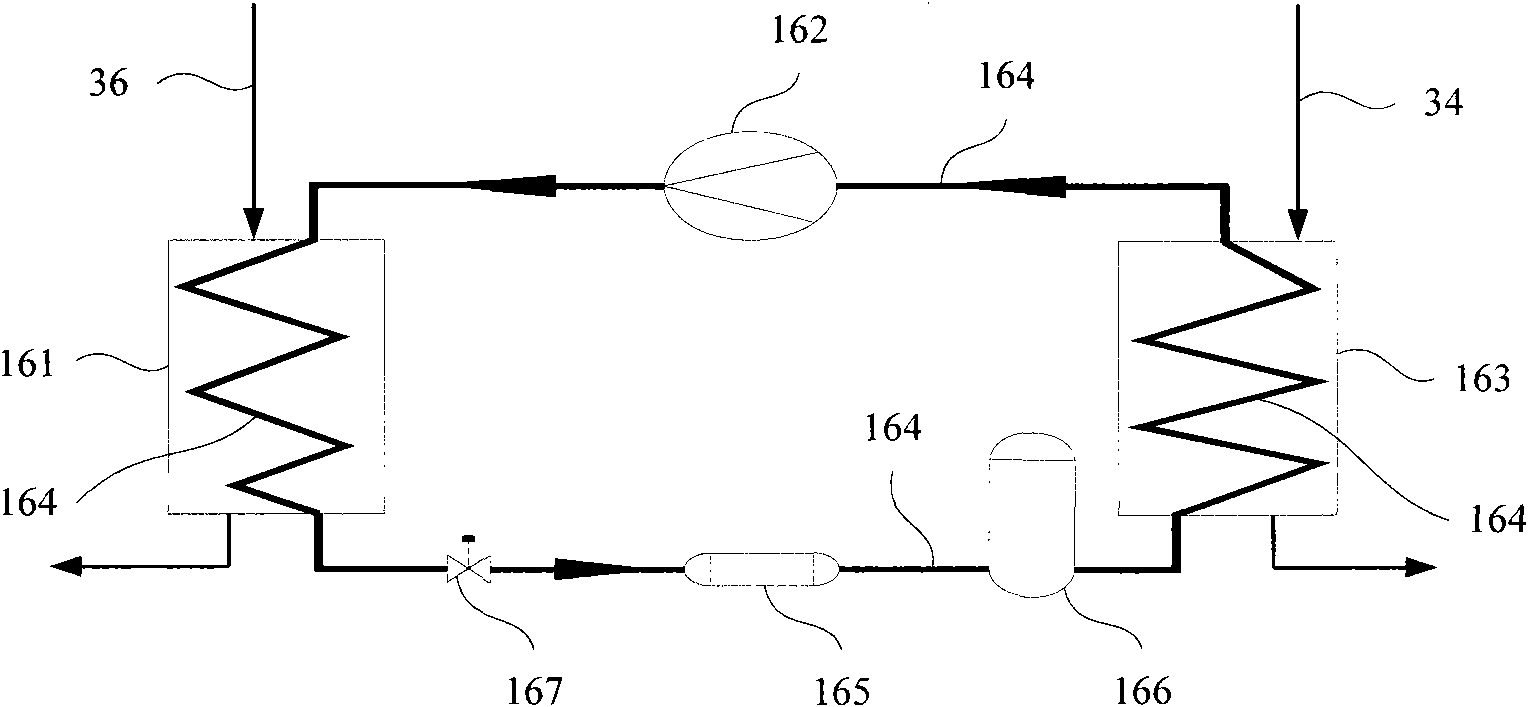

[0029] figure 1 A general architecture diagram of an exemplary embodiment of a drying system according to the present invention is shown. refer to figure 1 , the drying system at least includes: a drying box 10 , a fan 12 , a heat exchanger 14 , a heat pump module 16 , oil-water separators 18 a and 18 b and a gas circulation pipeline 20 . Wherein, the drying box 10 is connected with the fan 12 , and the heat exchanger 14 is an air-air heat exchange device, connected with the fan 12 and the heat pump module 16 and the heat pump module 16 is also connected with the drying box 10 . The drying box 10 is used for accommodating the spice raw materials to be dried, and the oil-water separators 18a and 18b are used for obtaining the essential oil contained in the spices. The gas circulation pipeline 20 is used to connect the drying box 10 , the blowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com