Method for preparing antioxidant peptides from oats by utilizing enzymatic membrane reactor

An enzyme membrane reactor, anti-oxidative peptide technology, applied in the preparation method of peptide, chemical instrument and method, peptide and other directions, can solve problems such as insufficient comprehensiveness, and achieve the effect of good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

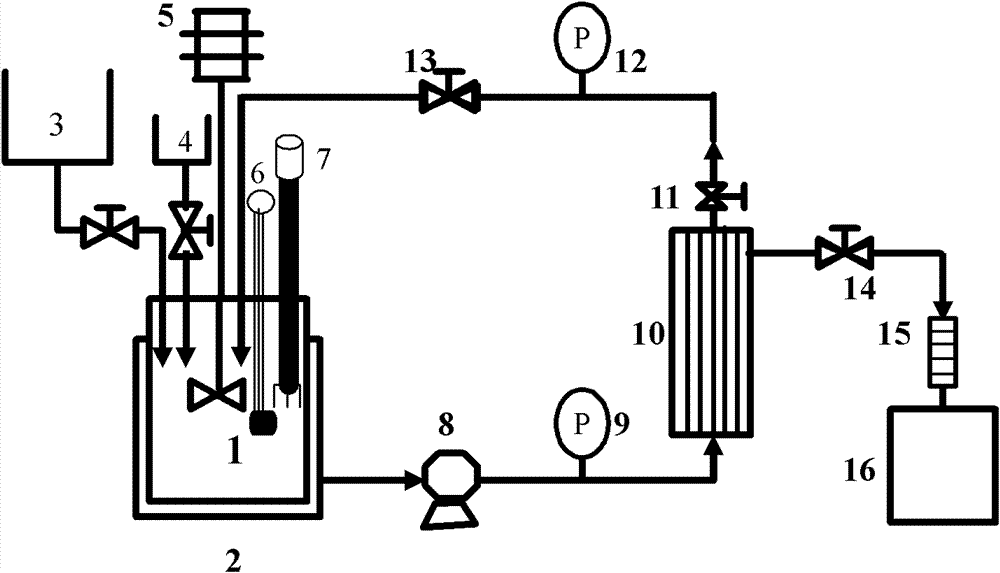

Method used

Image

Examples

Embodiment 1

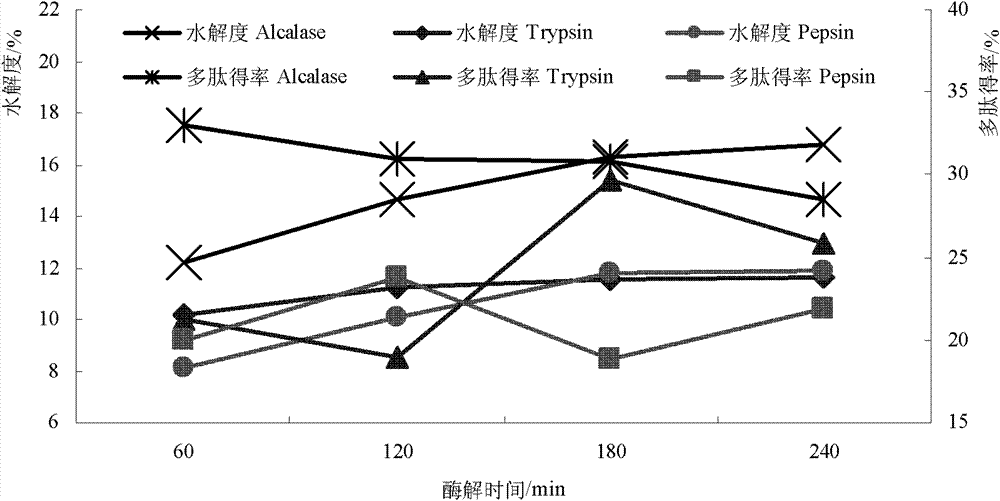

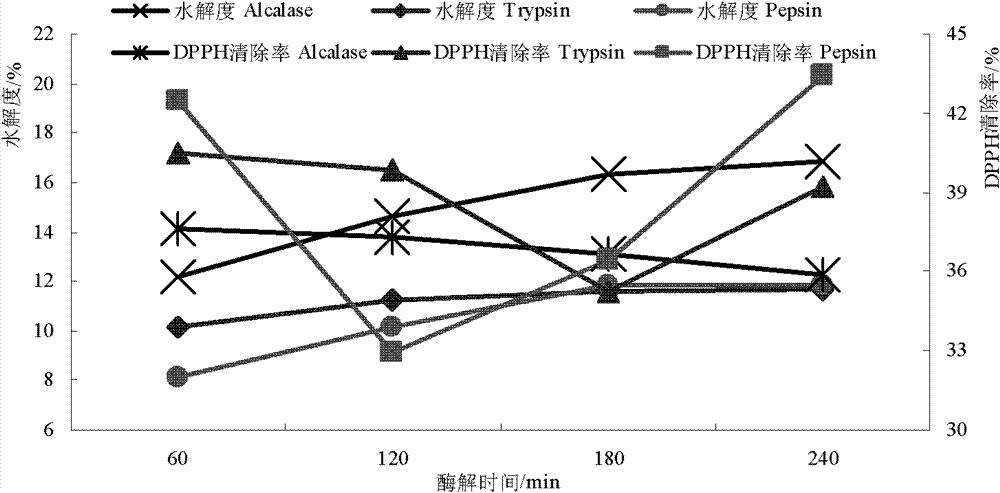

[0069] Embodiment 1, investigate the protease used for enzymatic hydrolysis oat gluten protein and enzymatic hydrolysis mode

[0070] (1) Determination of enzymatic hydrolysis index

[0071] First, a certain amount of oat gluten protein was weighed and placed in a constant temperature reactor, and the oat gluten protein was hydrolyzed according to the three protease hydrolysis conditions of Alcalase, Pepsin and Trypsin in Table 2. During the enzymolysis process, 1mol / L NaOH or Keep the pH value of the HCl solution constant, and record the consumption of NaOH or HCl solution. At the same time, take samples at 0min, 60min, 120min, 180min, and 240min, and place them in a boiling water bath for 15min to inactivate the enzyme and cool to room temperature. , adjust the pH value of the solution to the isoelectric point of oat gluten protein (pI=4.0), let it stand for 30min, centrifuge (10000r / min, 4°C, 10min), take the supernatant and adjust the pH value to 7.0; then, the The supern...

Embodiment 2

[0084] Embodiment 2, investigate the speed of Alcalase enzymolysis oat gluten protein

[0085] Studying the characteristics of Alcalase enzymatic hydrolysis of oat bran protein is a prerequisite for further optimizing the process of using Alcalase to prepare oat antioxidant peptides, and the enzymatic hydrolysis speed is the key to the study of Alcalase enzymatic hydrolysis characteristics of oat bran protein, because the speed of enzymatic hydrolysis It directly determines the feasibility of preparing antioxidant peptides by enzymatic membrane reactor. If the enzymatic hydrolysis of oat bran protein by Alcalase is too slow, oat bran protein will quickly form a gel layer on the membrane surface, and the membrane will be seriously polluted, resulting in enzymatic membrane reaction. The device stops working. Therefore, the rate of enzymatic hydrolysis was characterized by the consumption rate of NaOH, the effects of the size of the enzymatic hydrolysis system, the concentration ...

Embodiment 3

[0093] Embodiment 3, investigate the impact of enzyme membrane reactor system on enzyme activity

[0094] First, add 2500ml buffer solution (0.02mol / L pH value = 8.0 phosphate buffer) to the reaction tank, and add 12.5ml Alcalase, stir for 15min, take 5ml enzyme solution to measure its enzyme activity and absorbance at 280nm; then, turn off the ultra- Open the peristaltic pump at the permeate outlet of the filter membrane. The flow rate of the feed liquid is 25L / h. After 3 minutes of normal temperature and normal pressure circulation, open the outlet of the ultrafiltration membrane permeate and adjust the pressure to 0.01MPa. Add phosphate buffer solution to the system, record the amount added, open the pressure control valve, turn off the peristaltic pump, close the permeate outlet after each cycle for 60 minutes, measure the volume of the ultrafiltration membrane permeate, and measure its enzyme activity and 280nm Absorbance; Then, add the amount of buffer and the amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com