Separation method of pteroceltis tatarinowii fiber

A separation method and technology of green sandalwood, which are applied in fiber raw material processing, textile and papermaking, etc., can solve problems such as increasing drug consumption, and achieve the effects of reducing the amount of alkali, saving costs, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

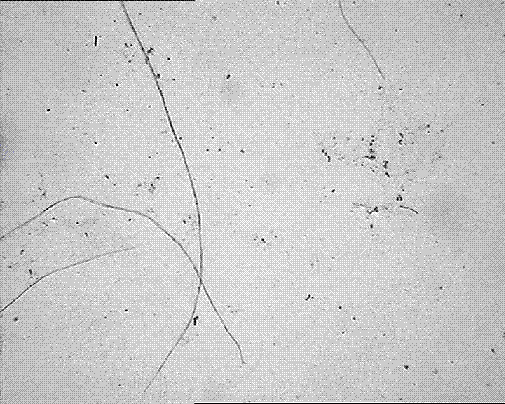

[0022] Example 1: The 2-year-old Pingtan stem bark was cut into small pieces of 2 mm × 20 mm, and 5 pieces were put into the pectinase solution of pH 4.0, the concentration of the pectinase solution was 1494.6 U / mg, and the temperature was 30 ° C. The soaking time is 2.5 hours; then rinse the stem bark fragments after enzyme treatment with distilled water and place them in 0.6% NaOH solution, keep the temperature at 80-85°C, and boil them for 25 minutes; take them out and rinse them with distilled water, put them in clean penicillin Add 2 mL of distilled water to the bottle, press it flat with a thick glass rod until it is broken, pour it into a 10 mL centrifuge tube, centrifuge at 3500 r / min for 5 min, carefully discard the supernatant, rinse the precipitate with 1 mL of distilled water; mix well Finally, take 1 drop with a dropper, spread it on a glass slide, dry and fix it on an alcohol lamp; then stain with 10% safranin for 10 min, wash it with distilled water, and examine ...

Embodiment 2

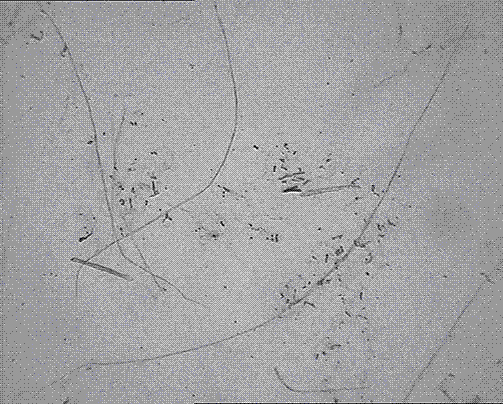

[0023] Example 2: Cut the 2-year-old Pingtan stem bark into small pieces of 2 mm × 20 mm, put 5 pieces into the pectinase solution with pH 4.5, the concentration of the pectinase solution is 1594.6 U / mg, and the temperature is 35 ° C. The soaking time is 3 hours; then the stem bark fragments after enzyme treatment are rinsed with distilled water and placed in 0.6% NaOH solution, kept at 80-85°C, boiled for 25 minutes; taken out, rinsed with distilled water, and put in clean penicillin Add 2 mL of distilled water to the bottle, press it flat with a thick glass rod until it is broken, pour it into a 10 mL centrifuge tube, centrifuge at 3500 r / min for 5 min, carefully discard the supernatant, rinse the precipitate with 1 mL of distilled water; mix well Finally, take 1 drop with a dropper, spread it on a glass slide, dry and fix it on an alcohol lamp; then stain with 10% safranin for 10 min, wash it with distilled water, and examine it under the microscope. Repeat 5 times, that is...

Embodiment 3

[0024] Example 3: The 3-year-old Pingtan stem bark was cut into small pieces of 2 mm × 20 mm, and 5 pieces were put into the pectinase solution of pH 5.0. The concentration of the pectinase solution was 1694.6 U / mg, and the temperature was 40 ° C. The soaking time is 3.5 hours; then the stem bark fragments after enzyme treatment are rinsed with distilled water, placed in 0.6% NaOH solution, kept at 80-85°C, and boiled for 25 minutes; taken out, rinsed with distilled water, and put in clean penicillin Add 2 mL of distilled water to the bottle, press it flat with a thick glass rod until it is broken, pour it into a 10 mL centrifuge tube, centrifuge at 3500 r / min for 5 min, carefully discard the supernatant, rinse the precipitate with 1 mL of distilled water; mix well Finally, take 1 drop with a dropper, spread it on a glass slide, dry and fix it on an alcohol lamp; then stain with 10% safranin for 10 min, wash it with distilled water, and examine it under the microscope. Repeat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com