Neutron shielding material and manufacturing method thereof

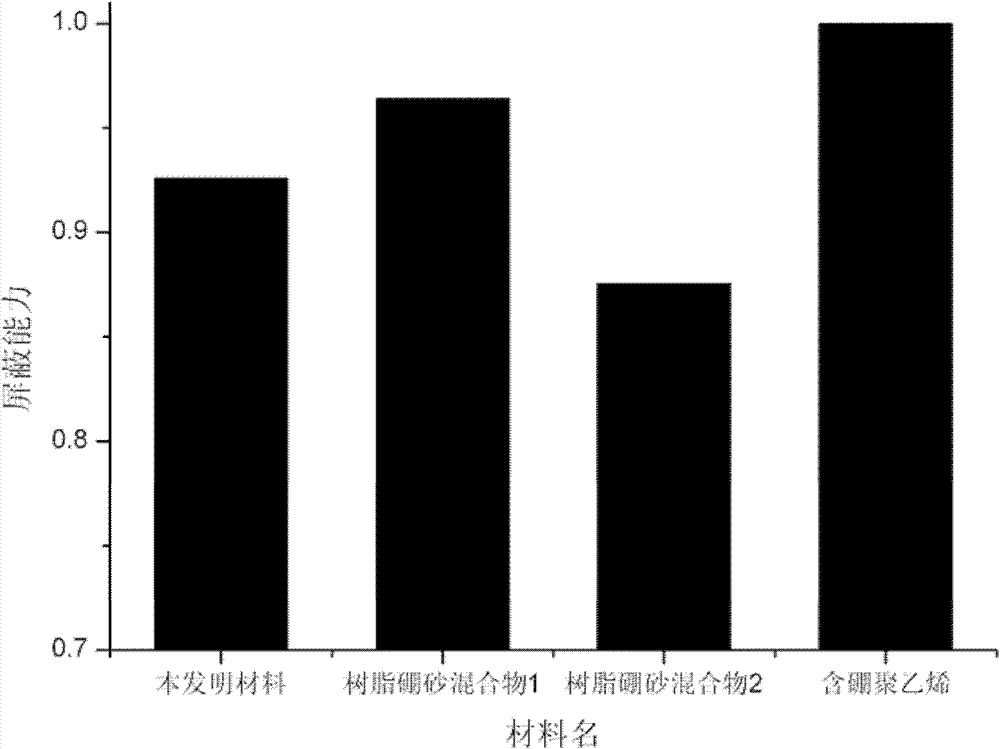

A technology of shielding material and manufacturing method, applied in shielding, manufacturing tools, reactors, etc., can solve the problems of slow molding speed, high cost, complicated process, etc., and achieve the effect of good neutron shielding ability, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

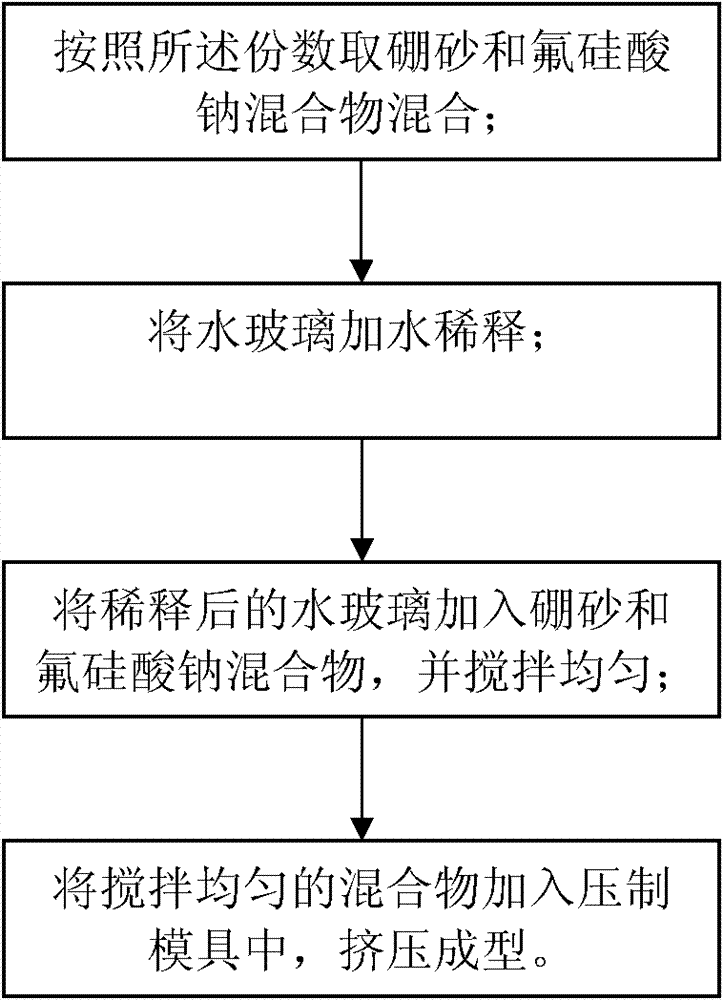

[0022] 1 Mix borax and sodium fluorosilicate mixture in parts by weight of 100:5; wherein, the ratio of parts by weight of borax, water glass and sodium fluorosilicate is 100:50:5;

[0023] 2 Dilute the water glass with water, the ratio of water is 1 / 10 to 1 / 15 of the water glass quality. A larger water ratio is good for stirring, but it will reduce the adhesive performance, and a dilution ratio of 1:10 is selected as a better balance point.

[0024] 3 Slowly add the diluted water glass to the mixture of borax and sodium fluorosilicate, and stir quickly.

[0025] 4 Add the well-stirred mixture into the pressing mold, extrude it, and use it after demoulding.

[0026] The initial setting time of the shielding material is 5-30 minutes (varies with the curing dose), the complete curing time is about 6-24 hours, and the curing temperature is room temperature.

Embodiment 2

[0028] 1 Mixing borax and sodium fluorosilicate mixture in parts by weight of 100:6; wherein, the ratio of parts by weight of borax, water glass and sodium fluorosilicate is 100:60:6;

[0029] 2 Dilute the water glass with water, the ratio of water is 1 / 12 of the water glass quality. A larger proportion of water facilitates stirring, but reduces adhesive properties.

[0030] 3 Slowly add the diluted water glass to the mixture of borax and sodium fluorosilicate, and stir quickly.

[0031] 4 Add the well-stirred mixture into the pressing mold, extrude it, and use it after demoulding.

[0032] The initial setting time of the shielding material is 5-30 minutes (varies with the curing dose), the complete curing time is about 6-24 hours, and the curing temperature is room temperature.

Embodiment 3

[0034] 1 Mix borax and sodium fluorosilicate mixture in parts by weight of 100:15; wherein, the ratio of parts by weight of borax, water glass and sodium fluorosilicate is 100:70:15;

[0035] 2 Dilute the water glass with water, the ratio of water is 1 / 15 of the water glass quality.

[0036] 3 Slowly add the diluted water glass to the mixture of borax and sodium fluorosilicate, and stir quickly.

[0037] 4 Add the well-stirred mixture into the pressing mold, extrude it, and use it after demoulding.

[0038] The initial setting time of the shielding material is 5-30 minutes (varies with the curing dose), the complete curing time is about 6-24 hours, and the curing temperature is room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com