A kind of corrosion-resistant high-strength neutron shielding alloy material and preparation method thereof

An alloy material and high-strength technology, which is applied in the field of high-strength neutron shielding alloy materials and their preparation, can solve problems such as failure to meet the requirements of corrosion resistance and mechanical properties that cannot meet the requirements of nuclear chemical equipment manufacturing, and achieve excellent neutron shielding. performance, improving comprehensive mechanical properties, and the effect of a single phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

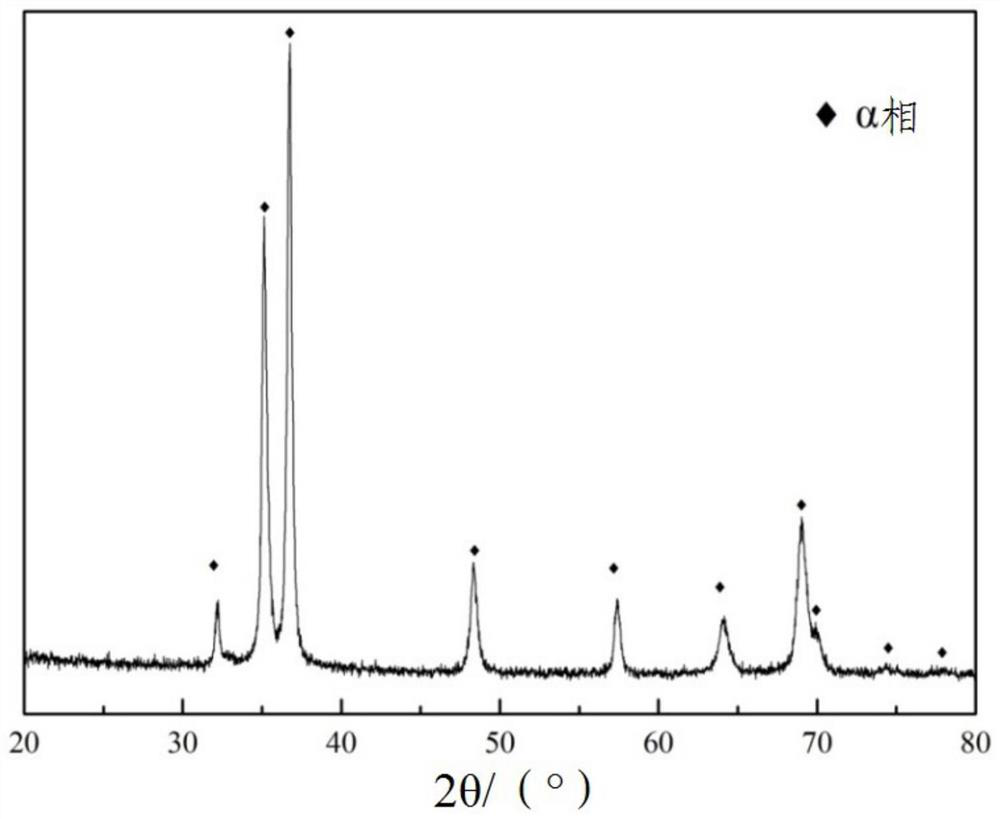

Image

Examples

Embodiment 1

[0030] The alloy material of this embodiment is composed of the following elements in mass percentage: Hf 50%, the balance is Zr and unavoidable impurities.

[0031] The alloy material preparation method of the present embodiment comprises the following steps:

[0032] Step 1. Mix zirconium sponge and hafnium sponge, and then press to obtain an electrode block, and then conduct vacuum consumable electrode melting on the obtained electrode block to obtain an alloy ingot; the zirconium sponge is in accordance with YS / T 397- 2015 standard industrial-grade zirconium sponge, the hafnium sponge is an industrial-grade hafnium sponge that meets the YS / T399-2013 standard;

[0033] Step 2. Carrying out machining and chamfering the alloy ingot obtained in step 1 in turn, and then performing three-fire secondary forging on the chamfered alloy ingot to obtain a forged alloy ingot; the three-fire secondary forging The conditions are as follows: successively upsetting and drawing three time...

Embodiment 2

[0042] The alloy material of this embodiment is composed of the following elements in mass percentage: Hf 49%, the balance is Zr and unavoidable impurities.

[0043] The alloy material preparation method of the present embodiment comprises the following steps:

[0044] Step 1. Mix zirconium sponge and hafnium sponge, and then press to obtain an electrode block, and then conduct vacuum consumable electrode melting on the obtained electrode block to obtain an alloy ingot; the zirconium sponge is in accordance with YS / T 397- 2015 standard industrial-grade zirconium sponge, the hafnium sponge is an industrial-grade hafnium sponge that meets the YS / T399-2013 standard;

[0045] Step 2. Carrying out machining and chamfering the alloy ingot obtained in step 1 in turn, and then performing three-fire secondary forging on the chamfered alloy ingot to obtain a forged alloy ingot; the three-fire secondary forging The conditions are as follows: upsetting twice at 1000°C, 900°C and 800°C in...

Embodiment 3

[0050] The alloy material of this embodiment is composed of the following elements in mass percentage: Hf 51%, the balance is Zr and unavoidable impurities.

[0051] The alloy material preparation method of the present embodiment comprises the following steps:

[0052] Step 1. Mix zirconium sponge and hafnium sponge, and then press to obtain an electrode block, and then conduct vacuum consumable electrode melting on the obtained electrode block to obtain an alloy ingot; the zirconium sponge is in accordance with YS / T 397- 2015 standard industrial-grade zirconium sponge, the hafnium sponge is an industrial-grade hafnium sponge that meets the YS / T399-2013 standard;

[0053] Step 2. Carrying out machining and chamfering the alloy ingot obtained in step 1 in turn, and then performing three-fire secondary forging on the chamfered alloy ingot to obtain a forged alloy ingot; the three-fire secondary forging The conditions are as follows: successively upsetting and drawing three time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com