Silicone resin modified epoxy resin-based neutron shielding material and its preparation and application

A technology of shielding material and epoxy resin, applied in the field of shielding materials, can solve the problem of large technical gap, and achieve the effect of simple and reliable preparation method and excellent neutron shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present embodiment provides a kind of preparation method of the epoxy resin modified by organosilicon resin, it comprises the following steps:

[0054] 100 parts by weight of bisphenol F type epoxy resin, 20 parts by weight of polymethyl silicone resin, 5 parts by weight of silane coupling agent (γ-aminopropyltriethoxysilane) and 0.5 parts by weight of catalyst two The dibutyltin laurate was mixed evenly, and then the obtained mixed system was reacted at 80° C. for 6 hours to obtain the silicone resin-modified epoxy resin.

Embodiment 2

[0056] Get 50 weight parts of anti-radiation auxiliary agent (boron carbide); ℃ vacuum drying, ready to use.

Embodiment 3

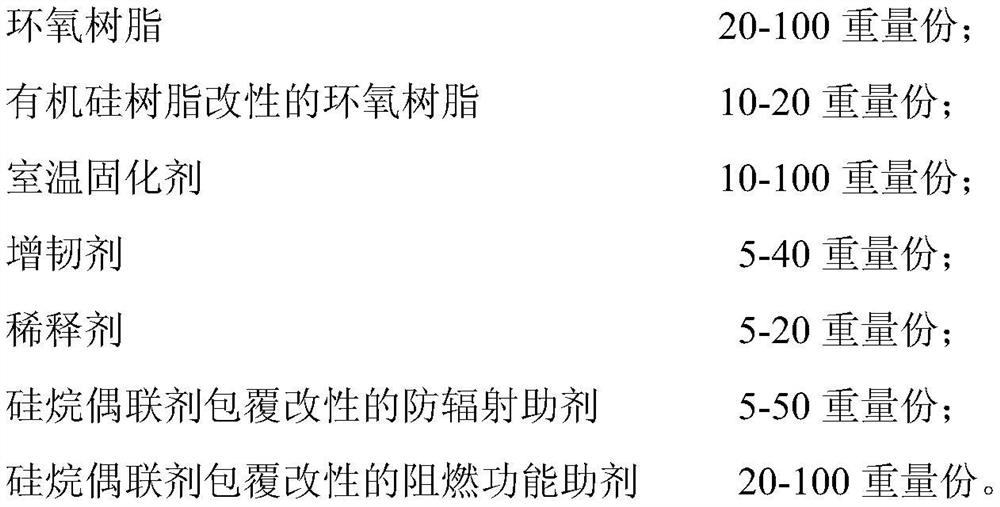

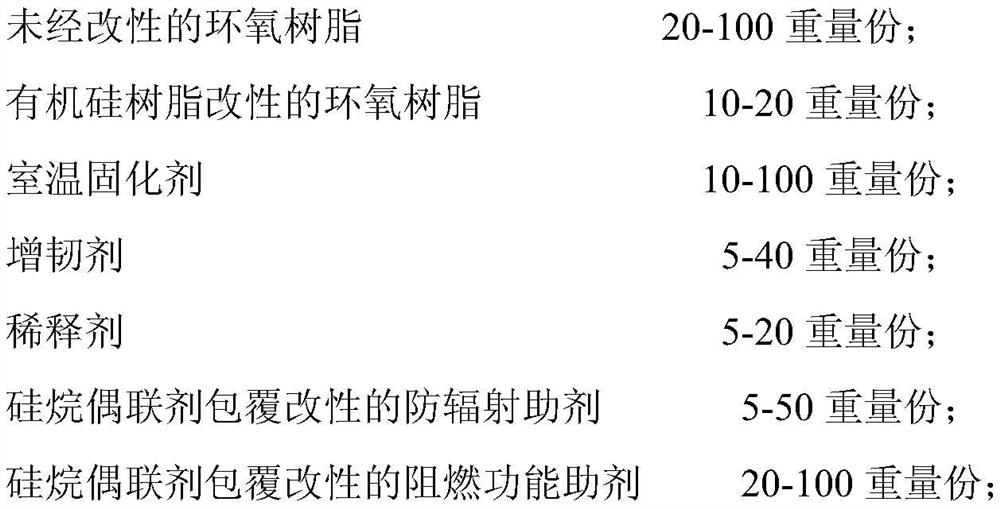

[0058] This embodiment provides a silicone-modified epoxy resin-based neutron shielding material, wherein the neutron shielding material is mainly prepared from the following raw material formula in parts by weight:

[0059] 100 parts by weight bisphenol F type epoxy resin;

[0060] The silicone resin modified epoxy resin prepared by the embodiment 1 of 10 parts by weight;

[0061] 30 parts by weight of aromatic amine room temperature curing agent;

[0062] The active end group of 20 parts by weight is the liquid rubber-modified epoxy resin of hydroxyl;

[0063] 10 parts by weight of allyl glycidyl ether;

[0064] The boron carbide that the embodiment 2 of 5 weight parts obtains;

[0065] Magnesium hydroxide or aluminum hydroxide prepared by the embodiment 2 of 40 parts by weight;

[0066] The preparation method of the silicone-modified epoxy resin-based neutron shielding material comprises the following steps:

[0067] (1), the epoxy resin modified by silicone resin, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com