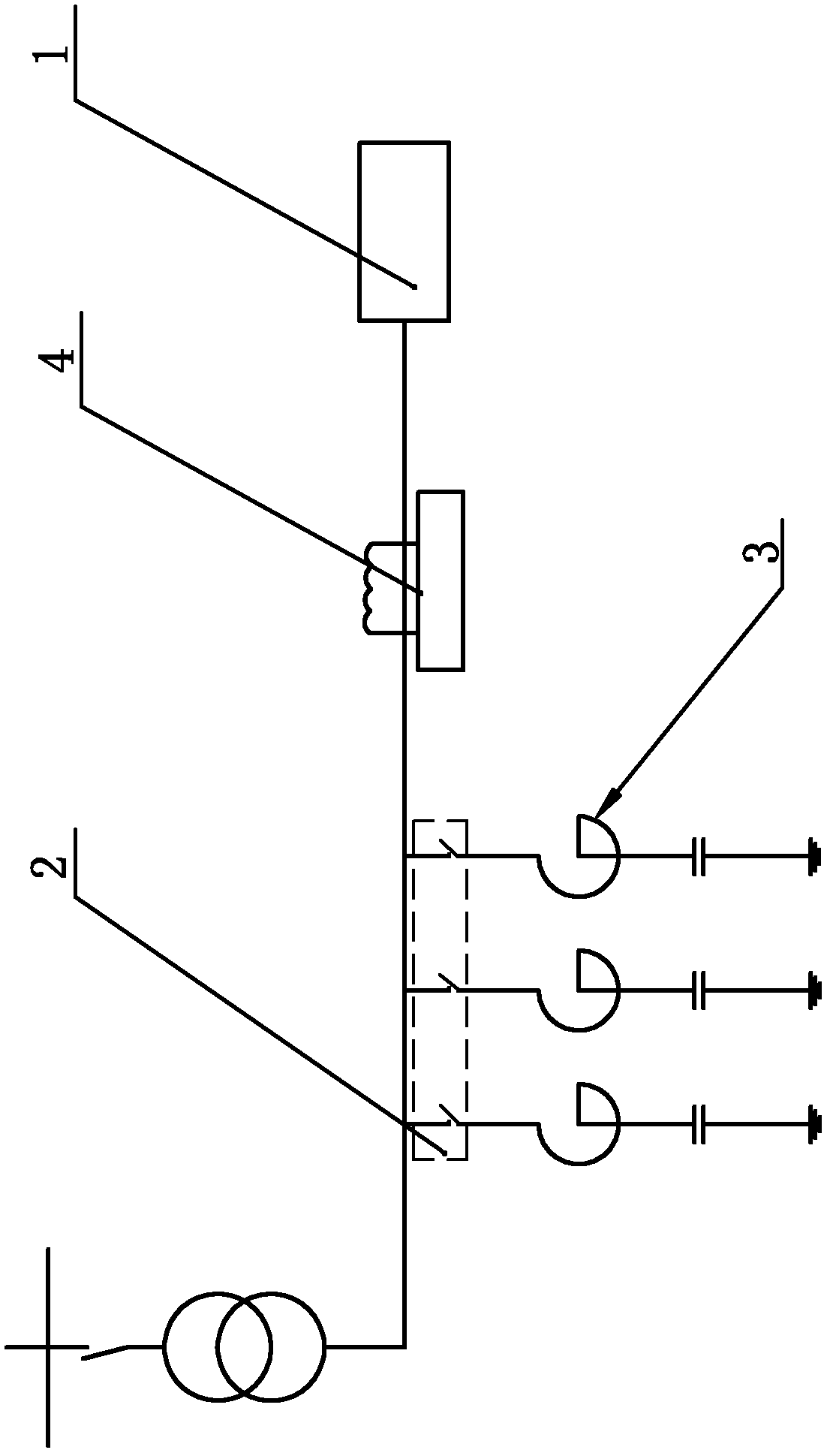

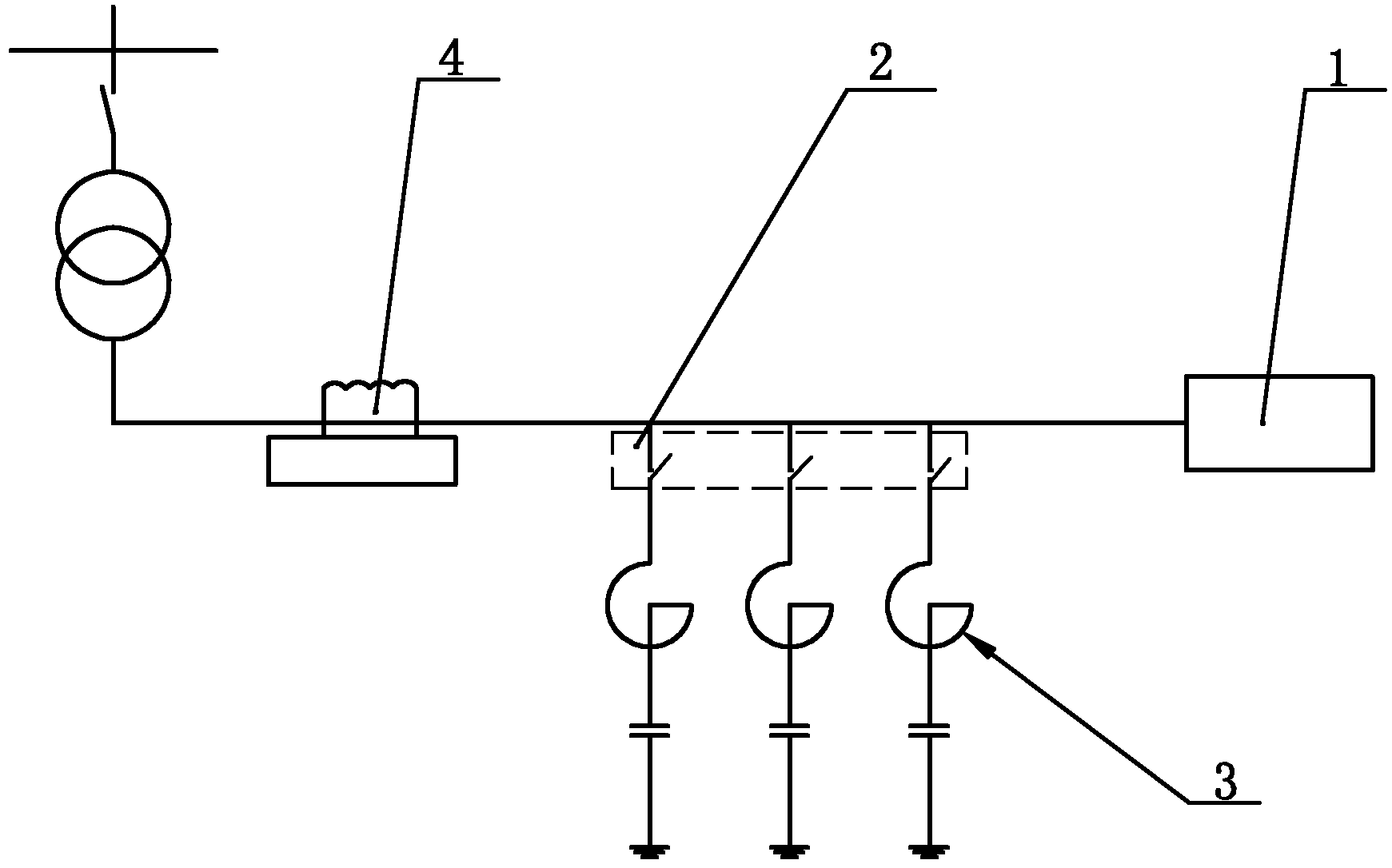

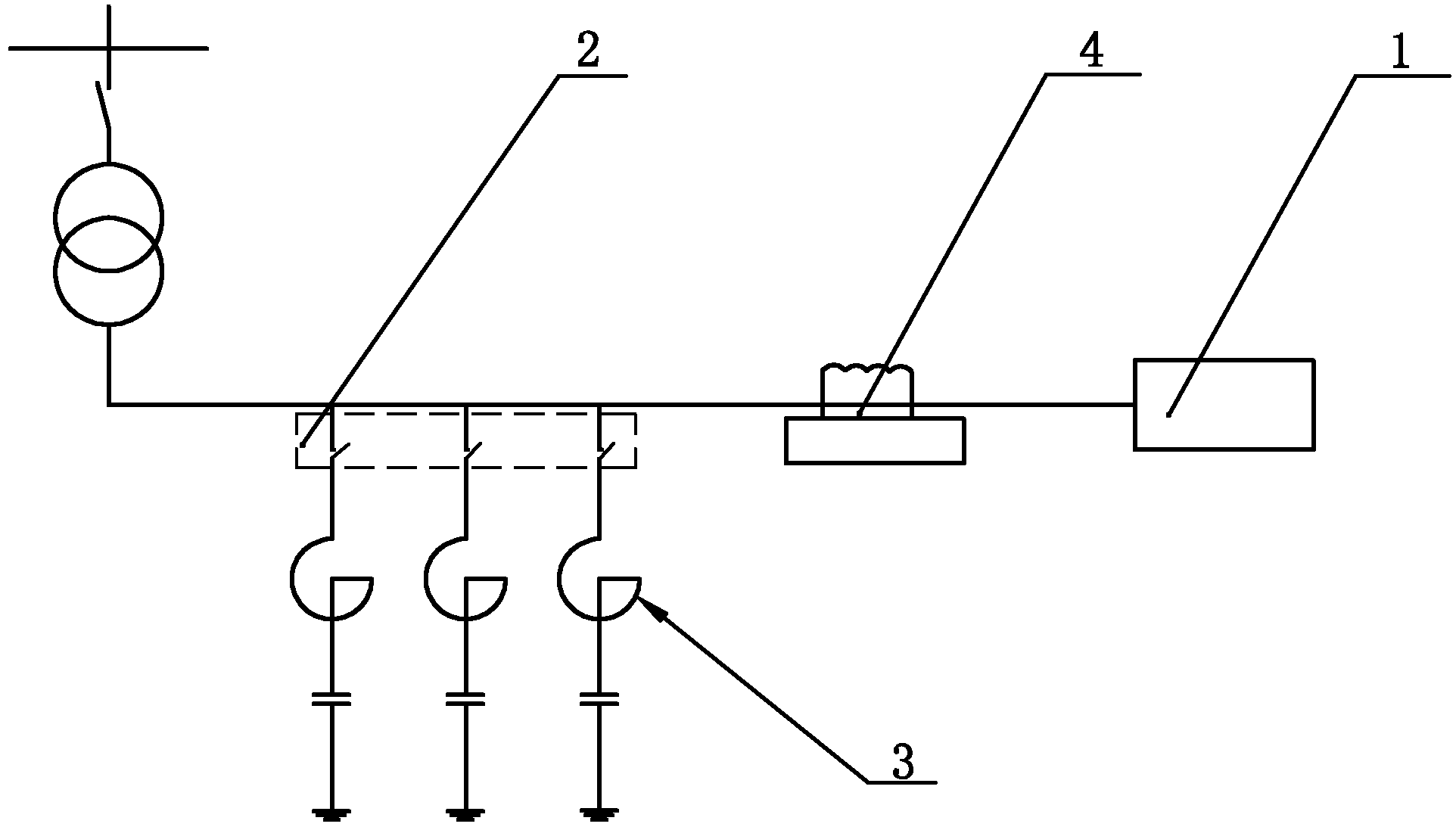

Filtering device of intermediate frequency smelting furnace

A filter device and melting furnace technology, applied in harmonic reduction devices, AC networks to reduce harmonics/ripples, etc., can solve problems affecting the safe operation of electrical equipment and power grids, excessive harmonic currents, overcompensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0015] A valve factory in Qingtian is equipped with a 0.5-ton intermediate frequency furnace. The transformer capacity is: 350 KVA, and the transformation ratio = 10KV / 0.4KV. After actual measurement, its PF (total power factor) cosφ 1 =0.93; reactive power = 249 Kvar, total current I rms =990A, THD V (Voltage Total Harmonic Distortion) = 16.0﹪; THD i (current total harmonic distortion) = 25.0﹪;

[0016] I 5 =184A I 7 =103A I 11 =56A

[0017] Q 5 =√3*Us*I 5 =127.5Kvar Q 5min =90.7 Kvar

[0018] Q 7 =√3*Us*I 7 =73.4Kvar Q 7min =49.3 Kvar

[0019] Q 11 =√3*Us*I 11 =38.8Kvar Q 7min =26.5Kvar

[0020] Q=∑Qn =239.7Kvar Q min =∑Qnmin =166.5Kvar

[0021] Meet the experience requirements of ∑Qn min ≦∑Qn.

[0022] Taking into account the production specifications of the capacitors, it was finally determined that:

[0023] Q 5 =150Kvar (one way) The switching current threshold is set to 500A;

[0024] Q 7 =72Kvar (one way) The switching current threshold is set t...

specific Embodiment 2

[0027] The basic parameters of the system design of a company in Jinyun County are as follows: transformer capacity = 630KVA, transformation ratio = 10KV / 0.4KV, rated current at the low-voltage side = 909.3A,

[0028] Considering the overload operation, the overload factor β=1.2 is taken. Since the system has not yet been put into production, and the intermediate frequency furnace is a current-type harmonic source, the harmonic current is approximately estimated by In =I1 / n (where I1 is the fundamental current value), I5 =909.3*1.2 / 5=218.6A, take 220A, I 7 =909.3*1.2 / 7=154.8A, take 155A, I 11 =909.3*1.2 / 11=99.1A, take 100A,

[0029] Compensation capacity, Q 5 =√3*Us*I 5 =152KVar, Q 7 =√3*Us*I 7 =107kvar, Q 11 =√3*Us*I 11 =69KVar

[0030] ∑Qn=Q 5 +Q 7 +Q 11 =328KVar, can be rounded up ∑Qn=152+100+70=320KVar

[0031] Filter Compensation Control Method

[0032] Q 5 =152Kvar (one way) The switching current threshold is set to 500A;

[0033] Q 7 =100Kvar (one way) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com