Use of surfactant/defoamer mixtures for enhanced metals loading and surface passivation of silicon substrates

A technology of surfactant and defoaming agent, applied in the field of products manufactured by this method, can solve problems such as damage to incinerator construction materials, unacceptable incineration system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

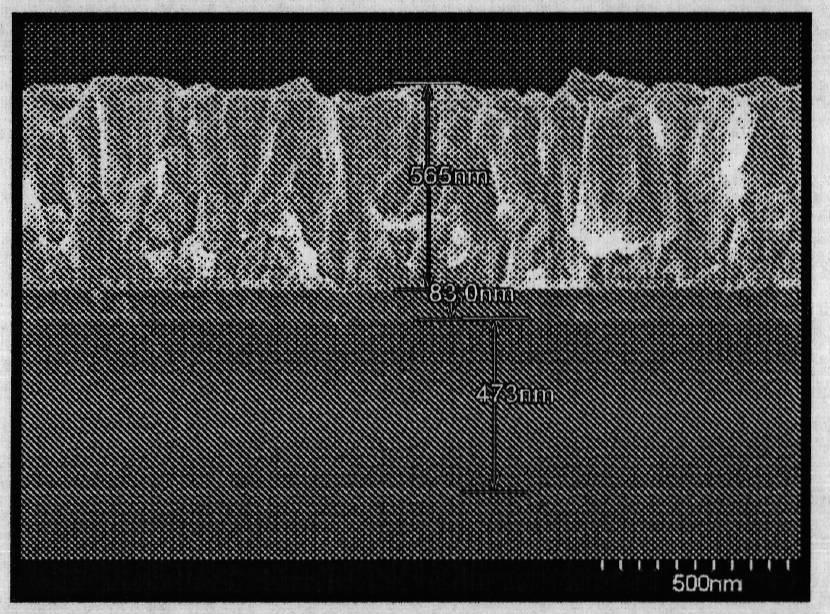

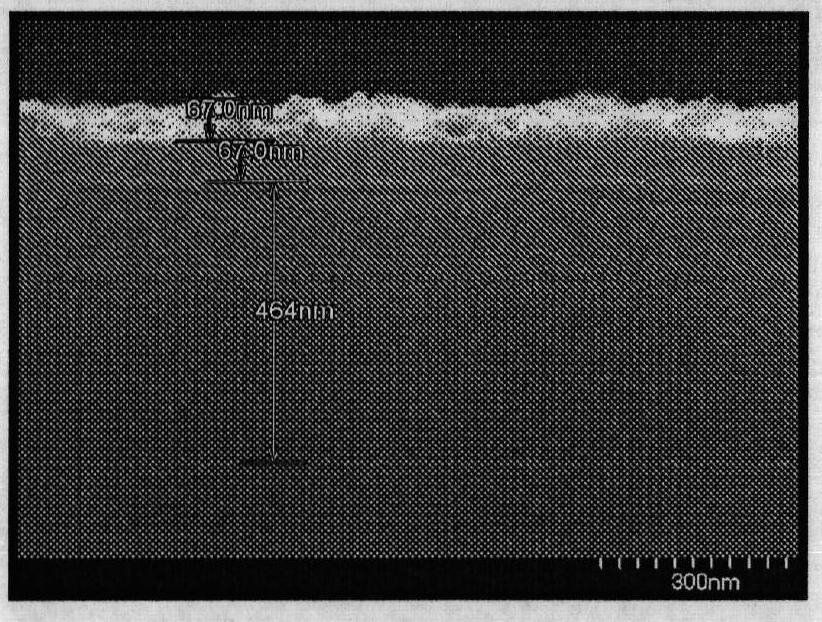

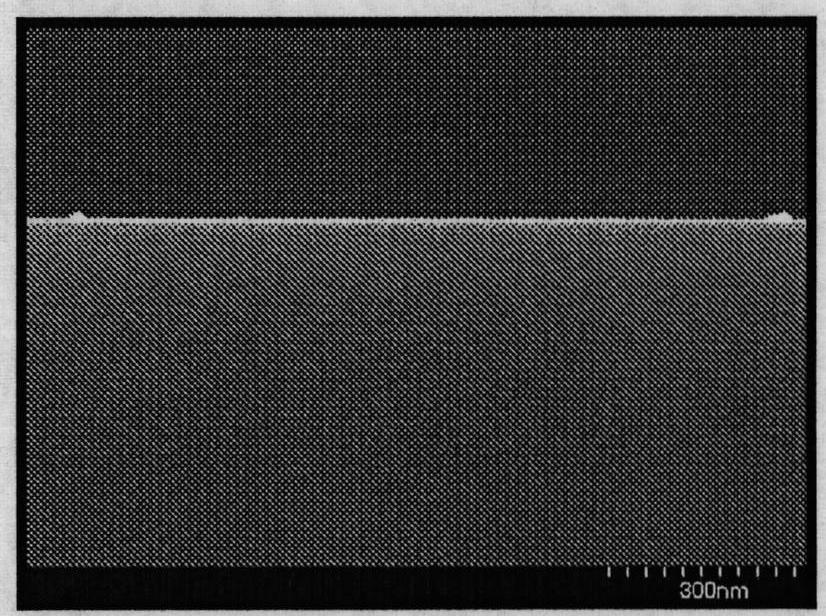

Image

Examples

example 1

[0113] A concentrated removal composition was prepared as follows: 6.75% by weight NHCl, 43.6% by weight water, 30% by weight HF (49%), 15% by weight HEDP (60%), 4.5% by weight Dowfax3B2 (45%) (Dowfax3B2 is as 45% by weight % solution purchased and used as such) and 0.15% by weight of antifoaming agent, wherein the antifoaming agent is RA20 (Formulation A), P1 (Formulation B), 17R2 (Formulation C), 17R4 (Formulation D), or One of 25R2 (Formulation E). Each concentrated composition was diluted 2:1 with 30% hydrogen peroxide (ie, 2 parts concentrate to 1 part 30% H2O2) prior to use.

[0114] Another set of concentrated removal compositions was prepared as follows: 6.75% by weight NHCl, 47.5% by weight water, 30% by weight HF (49%), 15% by weight HEDP (60%), and 0.75% by weight Foaming agent is RA20 (Formulation F), P1 (Formulation G), 17R2 (Formulation H), 17R4 (Formulation I), or One of 25R2 (Formulation J). Each concentrated composition was diluted 2:1 wit...

example 2

[0131] A concentrated removal composition was prepared as follows: 4.5% by weight NH4Cl, 20% by weight HF (49%), 10% by weight HEDP (60%), 3.04% by weight Dowfax3B2 (45%), 0.104% by weight 25R2, 33.4% by weight H2O2 (30%), additional substances in the amounts shown in Table 5, and the balance is water, wherein such additional substances are diethylene glycol monobutyl ether (hereinafter referred to as BC), dipropylene glycol monobutyl ether Propyl ether (hereinafter referred to as DPGPE) or propylene glycol (hereinafter referred to as PG). The foam height test described in Example 1 was performed at room temperature and the results are shown in Table 5.

[0132] Table 5: Foaming at room temperature for different removal compositions

[0133]

example 3

[0135] Prepare the following formulations:

[0136] Formulation M: 4.5 wt% NH 4 Cl, 20 wt% HF (49%), 10 wt% HEDP (60%), 3 wt% Dowfax 3B2 (45%), 0.1 wt% Super Defoamer 225, 33.4 wt% H 2 o 2 (30%), 29% by weight water

[0137] Formulation N: 4.5 wt% NH 4 Cl, 20 wt% HF (49%), 10 wt% HEDP (60%), 3 wt% Dowfax3B2 (45%), 0.1 wt% 31R2, 33.4 wt% H 2 o 2 (30%), 29% by weight water

[0138] Formulation O: 4.5 wt% NH 4 Cl, 20 wt% HF (49%), 10 wt% HEDP (60%), 3 wt% Dowfax3B2 (45%), 0.5 wt% 25R2, 33.4 wt% H 2 o 2 (30%), 2% by weight sodium toluenesulfonate, 26.6% by weight water

[0139] Formulation P: 4.5% by weight NH 4 Cl, 20 wt% HF (49%), 10 wt% HEDP (60%), 3 wt% Dowfax3B2 (45%), 0.07 wt% Super Defoamer 225, 33.4 wt% H2O2 (30%), 29.03 wt% water

[0140] Formulation Q: 4.5 wt% NH 4 Cl, 20 wt% HF (49%), 10 wt% HEDP (60%), 3 wt% Dowfax 3B2 (45%), 0.02 wt% Super Defoamer 225, 33.4 wt% H 2 o 2 (30%), 29.08% by weight water

[0141] Formulation R: 4.5 wt% NH 4 Cl, 20 wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com