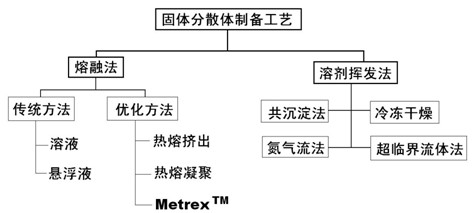

Preparation method for nano-granular solid dispersion of hydrophobic drug by high-voltage electrostatic spraying

A technology of high-voltage electrostatic spraying and hydrophobic drugs, which is applied in the direction of making drugs into special physical or ingestible devices, etc., which can solve the problem that the degree of entanglement of polymer molecules cannot be guaranteed, the stability of solid dispersions is not good, and it should not be too high Problems such as clogging of the spinning head, etc., achieve the effect of low cost, fast drying and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] High-voltage electrostatic spraying prepares hydrophobic drug nanoparticles--the method for paracetamol solid dispersion, comprising the steps:

[0051] (1) Preparation of paracetamol and polymer spinning solution

[0052] Polyvinylpyrrolidone (PVP K25) is used as the drug-loaded polymer substrate, and ethanol is used as the solvent to add paracetamol and the drug-loaded polymer substrate according to the mass ratio, that is, the ratio of paracetamol: drug-loaded polymer substrate is 1:10 Dissolve in an ethanol solvent to prepare a transparent and clear eutectic electrospray solution;

[0053] The eutectic electrospray solution is calculated by mass percentage, wherein the PVP content is 20%, the paracetamol content is 2%, and the rest are ethanol solvents;

[0054] (2), preparation of paracetamol solid dispersion

[0055] The eutectic electrospray solution obtained in step (1) was subjected to high-voltage electrostatic spraying, the flow rate of the high-voltage ele...

Embodiment 2

[0065] High-voltage electrostatic spraying prepares hydrophobic drug nanoparticles--the method for paracetamol solid dispersion, comprising the steps:

[0066] (1) Preparation of paracetamol and polymer spinning solution

[0067] Polyvinylpyrrolidone (PVP K25) is used as the drug-loaded polymer substrate, and ethanol is used as the solvent to mix paracetamol and the drug-loaded polymer substrate according to the mass ratio, that is, the ratio of paracetamol: drug-loaded polymer substrate is 5:10 Added to ethanol for dissolution to prepare a transparent and clear eutectic electrospray solution;

[0068] In the co-dissolving electrospray solution, calculated by mass percentage, the PVP content is 20%, the paracetamol content is 10%, and the rest is ethanol solvent;

[0069] (2), preparation of paracetamol solid dispersion

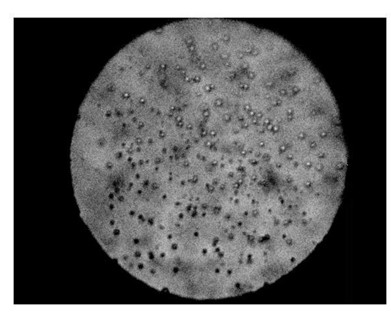

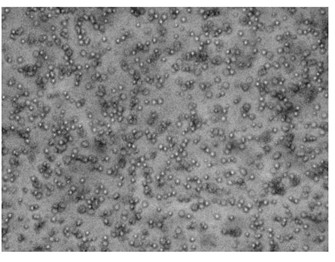

[0070] The co-dissolution electrospray solution obtained in step (1) was subjected to high-voltage electrostatic spraying according to the conditions of Ex...

Embodiment 3

[0072] High-voltage electrostatic spraying prepares hydrophobic drug nanoparticles--the method for paracetamol solid dispersion, comprising the steps:

[0073] (1) Preparation of paracetamol and polymer spinning solution

[0074] Polyvinylpyrrolidone (PVP K25) is used as the drug-loaded polymer substrate, and ethanol is used as the solvent to mix paracetamol and the drug-loaded polymer substrate according to the mass ratio, that is, the ratio of paracetamol: drug-loaded polymer substrate is 5:20 Add it to ethanol solvent for dissolution to prepare a transparent and clear eutectic electrospray solution;

[0075] In the co-dissolving electrospray solution, calculated by mass percentage, the PVP content is 20%, the paracetamol content is 5%, and the rest is ethanol solvent;

[0076] (2), preparation of paracetamol solid dispersion

[0077] The co-dissolution electrospray solution obtained in step (1) was subjected to high-voltage electrostatic spraying according to the conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com