Valve rod automatic machining machine

An automatic processing and valve stem technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing cost, low processing precision, low processing efficiency, etc., and achieve consistent processing quality and low processing cost , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

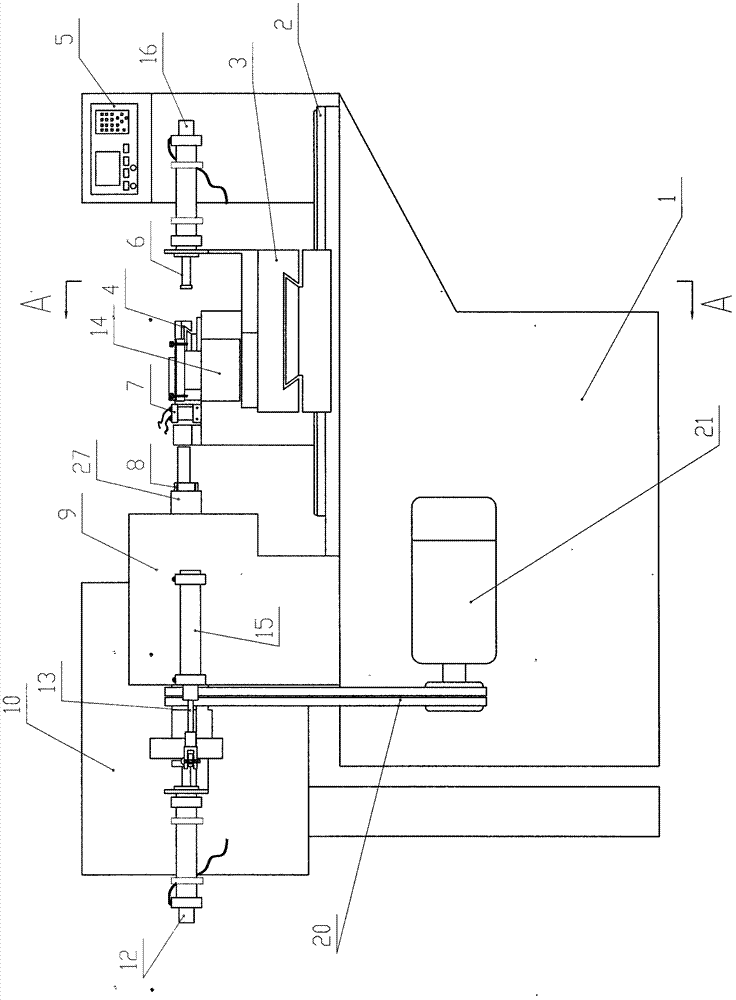

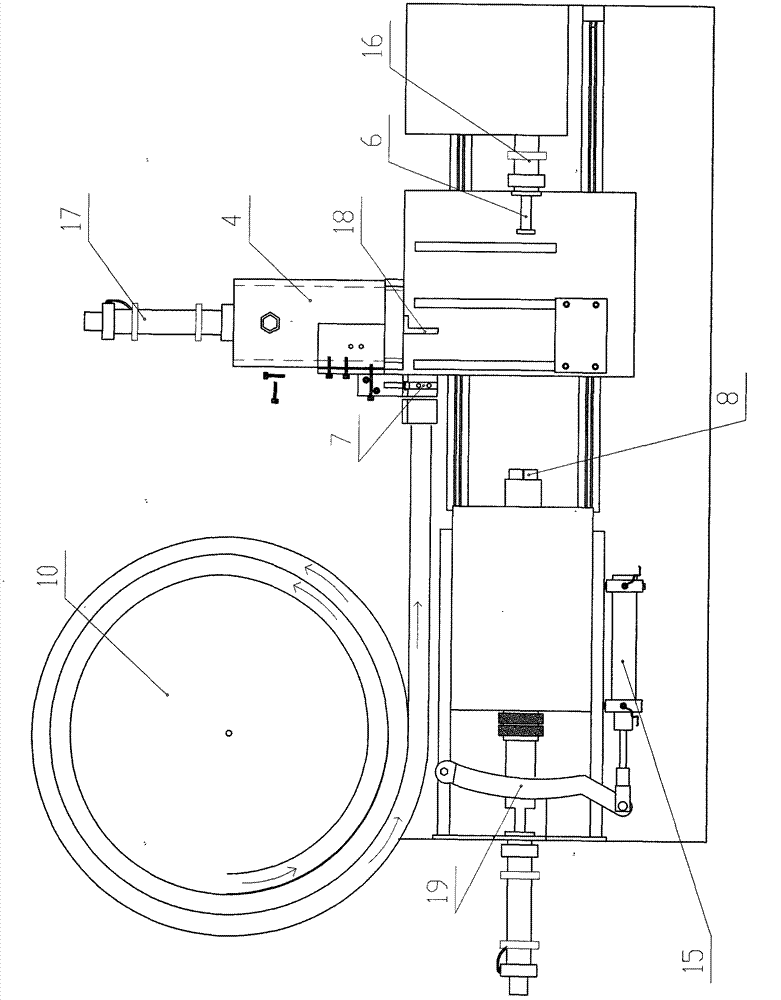

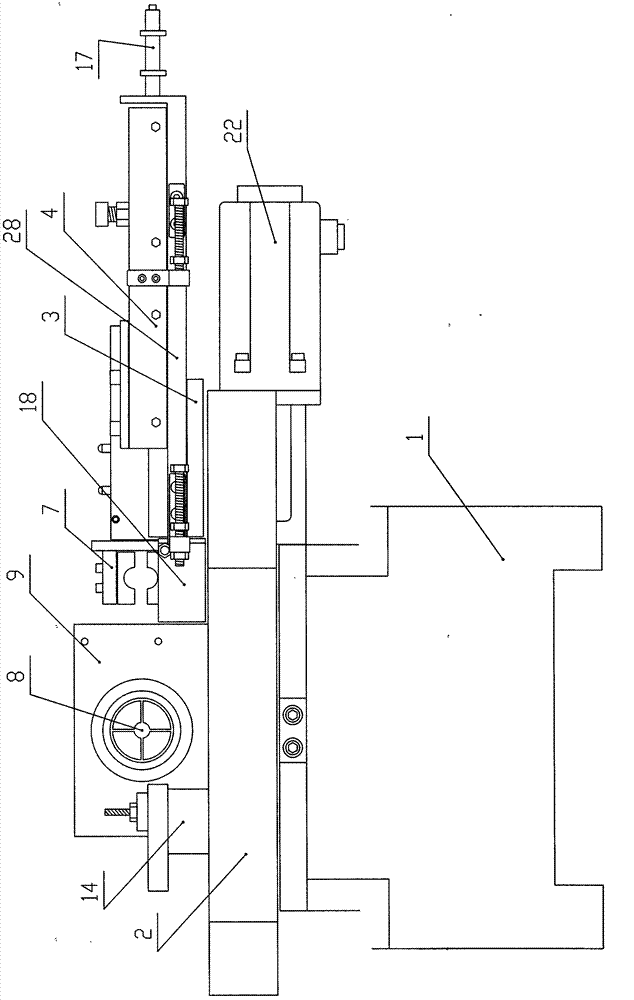

[0013] Such as figure 1 The valve stem automatic processing machine shown includes a main frame 1, a tool holder 14, a horizontal carriage 2, a longitudinal carriage 3, a headstock 9, a main shaft 27, a collet 8, a motor 21, and a tail box. The main shaft 27 is installed on the main shaft In the box 9, the rotating shaft of the motor 21 is connected with the belt 20, and the knife rest 14 is installed on the main frame 1 through the horizontal carriage 2 and the longitudinal carriage 3.

[0014] An automatic feeding device is provided on the main machine platform 1 opposite to the knife rest 14. The automatic feeding device is composed of a material conveying tray 10, a secondary longitudinal carriage 4, a pneumatic manipulator 7 and a limit block 18. The auxiliary longitudinal carriage 4 The pallet 28 is fixedly mounted on the main frame 1, the pneumatic manipulator 7 is fixedly mounted on the secondary longitudinal pallet 4, the limit block 18 is fixedly mounted on the palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com