Portable central processing unit (CPU) controlled high-power electric welding machine

A portable, electric welding machine technology, applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of heavy waste of raw materials, unstable output current, poor welding effect, etc., to maximize the heat dissipation effect and increase the air volume , The effect of reducing the radiator area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

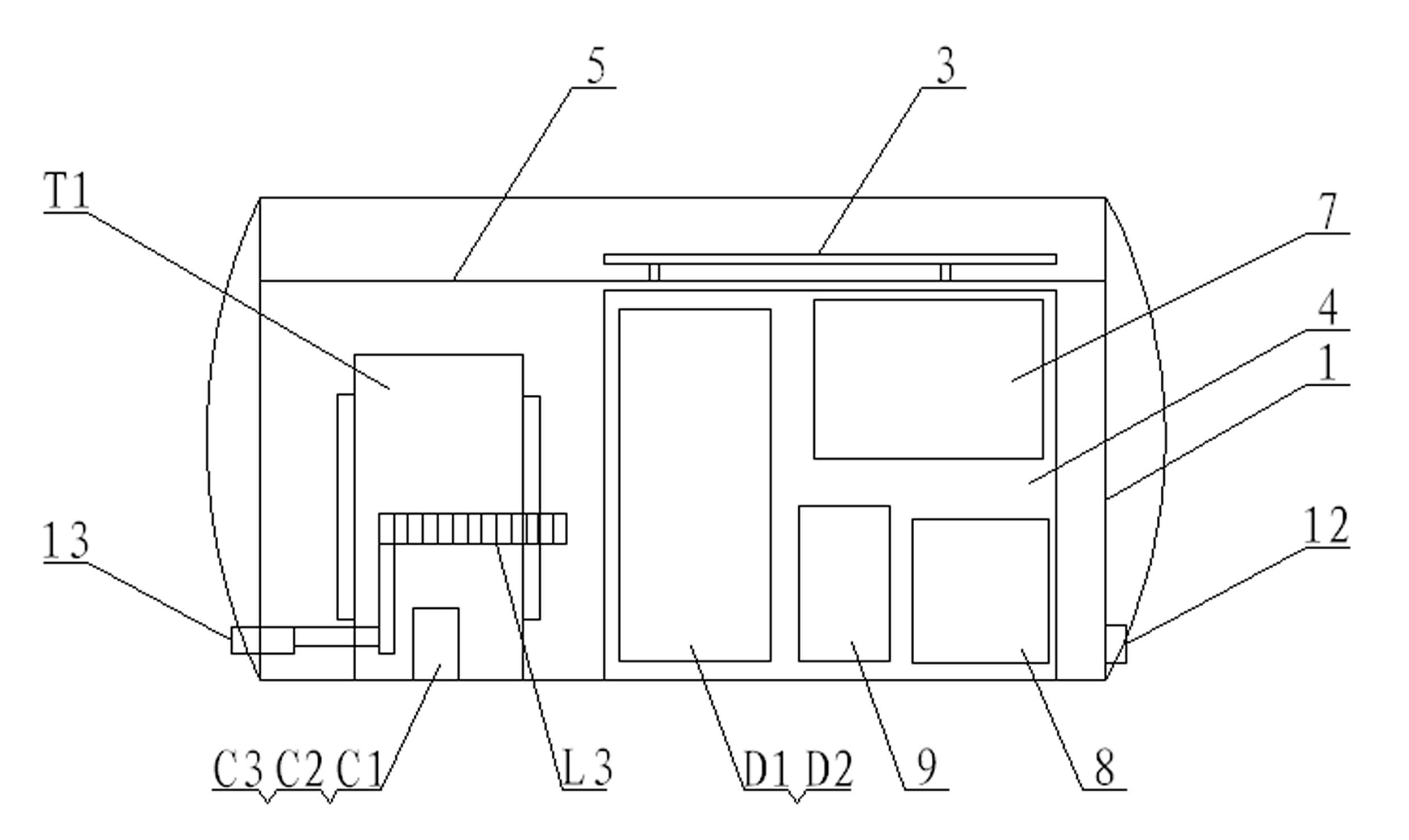

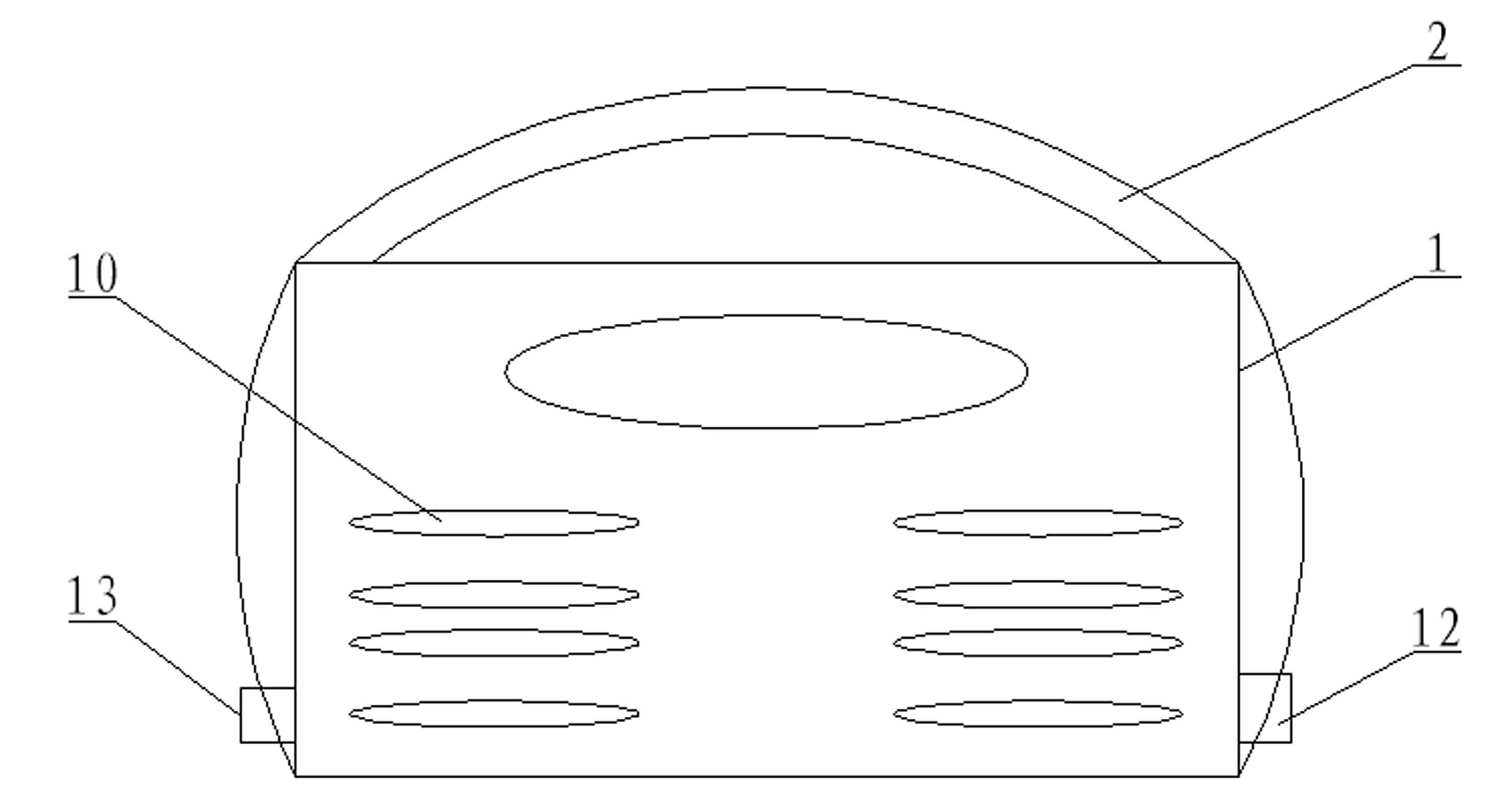

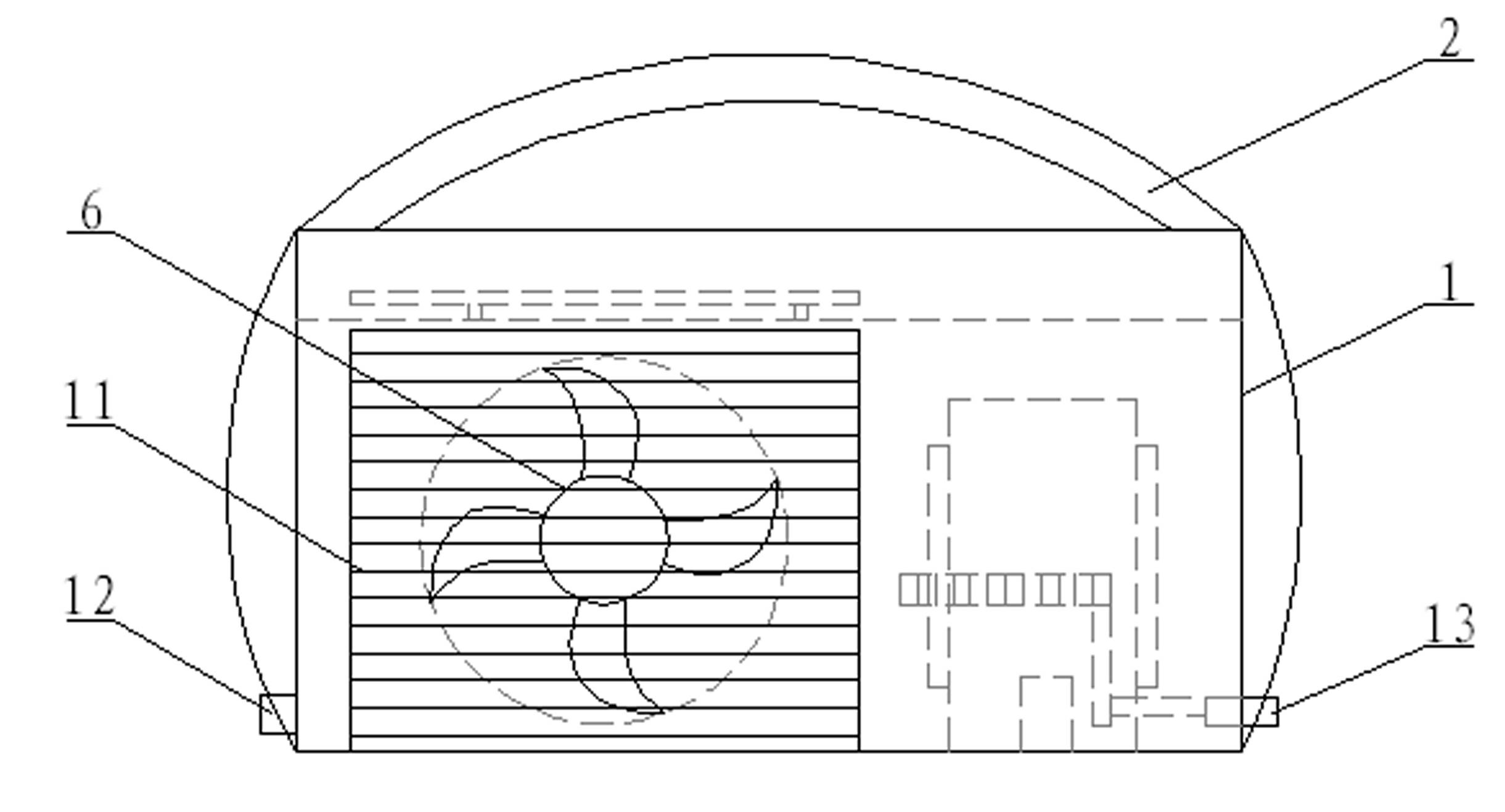

[0027] Figure 1-5As shown, a CPU-controlled high-power portable electric welding machine includes a casing 1, a handle 2, a CPU-controlled circuit board 3, a radiator 4, a shielding layer 5, a fan 6, a full-bridge high-frequency conversion circuit 7, an input module 8, and a control transformer 9. Two resonant inductors L1, L2, high frequency transformer T1, two fast recovery diodes D1, D2, input filter capacitor C1, resonant capacitor C2, output filter capacitor C3 and ferrite reactor L3. The upper part of the housing 1 is connected to the handle 2, the front panel of the housing 1 is provided with an air outlet 10, the rear panel of the housing 1 is provided with an air inlet 11, and a shielding layer 5 is arranged horizontally in the housing 1 to divide the inner cavity of the electric welding machine into upper and lower parts, and the CPU controls the circuit board 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com