Manufacturing method of vehicular interior decorating material

A manufacturing method and technology for interior trim, applied in the field of manufacturing interior materials for vehicles, can solve problems such as limitations, and achieve good appearance, guaranteed adhesion, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

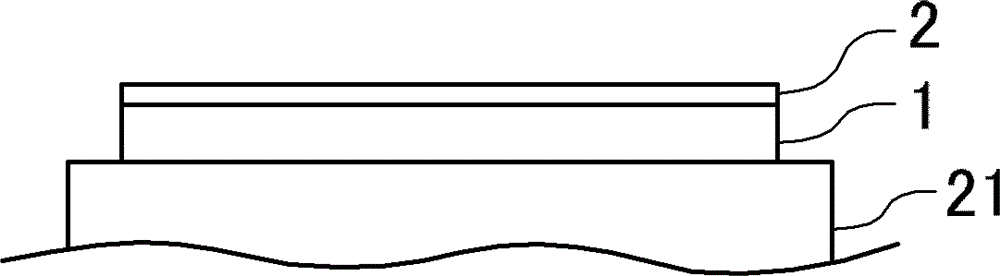

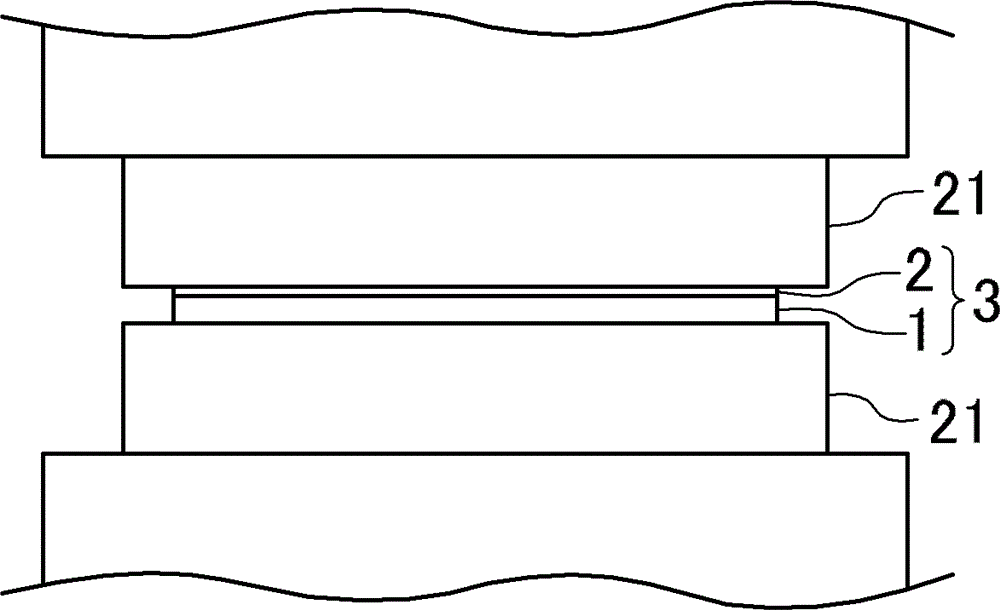

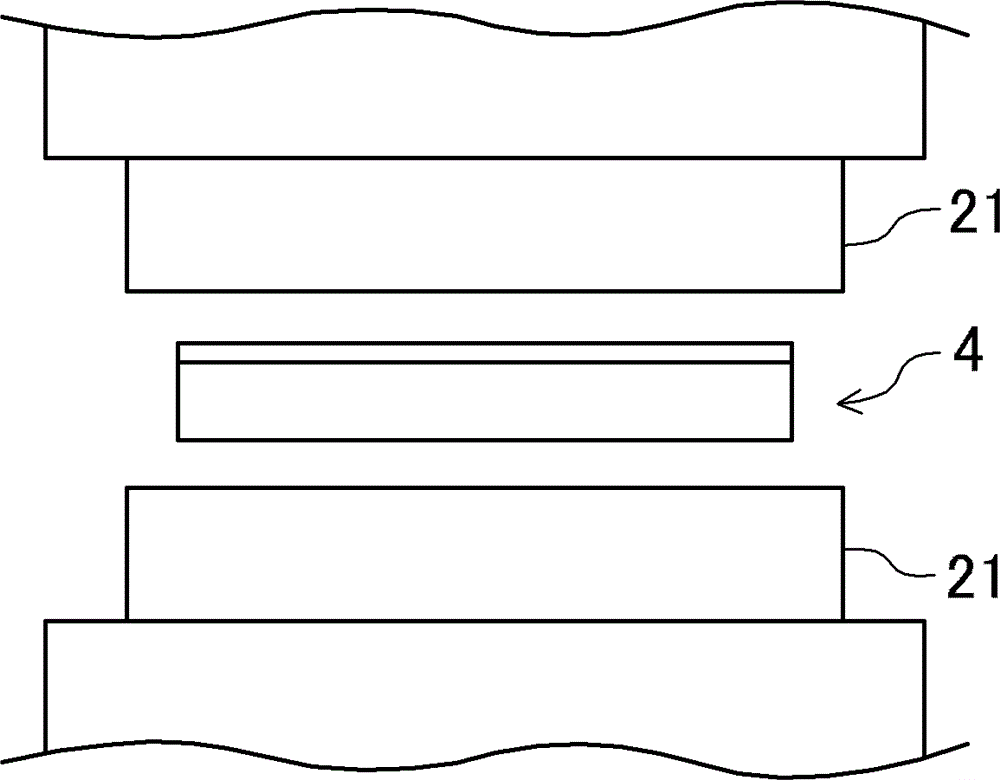

[0120] stampable sheet

[0121] Thermoplastic resin: polypropylene particles (weight average molecular weight 200,000, MFR65g / 10min, average particle diameter Melting point 165°C)

[0122] Reinforcement fiber: glass fiber (length 25mm, average diameter 13μm)

[0123] Thermally expandable particles:

[0124] Surface material

[0125] Polyester organic fiber non-woven fabric (thickness 1.2mm)

[0126] Resin sheet (resin film)

[0127] Polypropylene with a thickness of 40 μm (MFR65, melting point 160°C)

[0128] polyamide fiber

[0129] Nylon 6 with a thickness of 25 μm (melting point 215°C)

[0130] Spunbond nonwoven fabric

[0131] Polyester fiber spunbonded non-woven fabric (weight per unit area 13g / m 2 , thickness 0.08mm)

[0132]The dispersion is prepared by adding 0.5 g / L of surfactant, namely sodium dodecylbenzenesulfonate, to 1.5 liters of water and then stirring to prepare a bubble containing tiny bubbles, and then adding A raw material formed of 40% by dry...

Embodiment 2

[0141] Other conditions were the same as in Example 1 except that the length of the reinforcing fibers, namely glass fibers, was 25 mm and the average diameter thereof was 11 μm.

Embodiment 3

[0143] Other conditions were the same as in Example 1 except that the length of the reinforcing fibers, namely glass fibers, was 25 mm and the average diameter was 7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com