Organic silicon episulfide resin and preparation method thereof

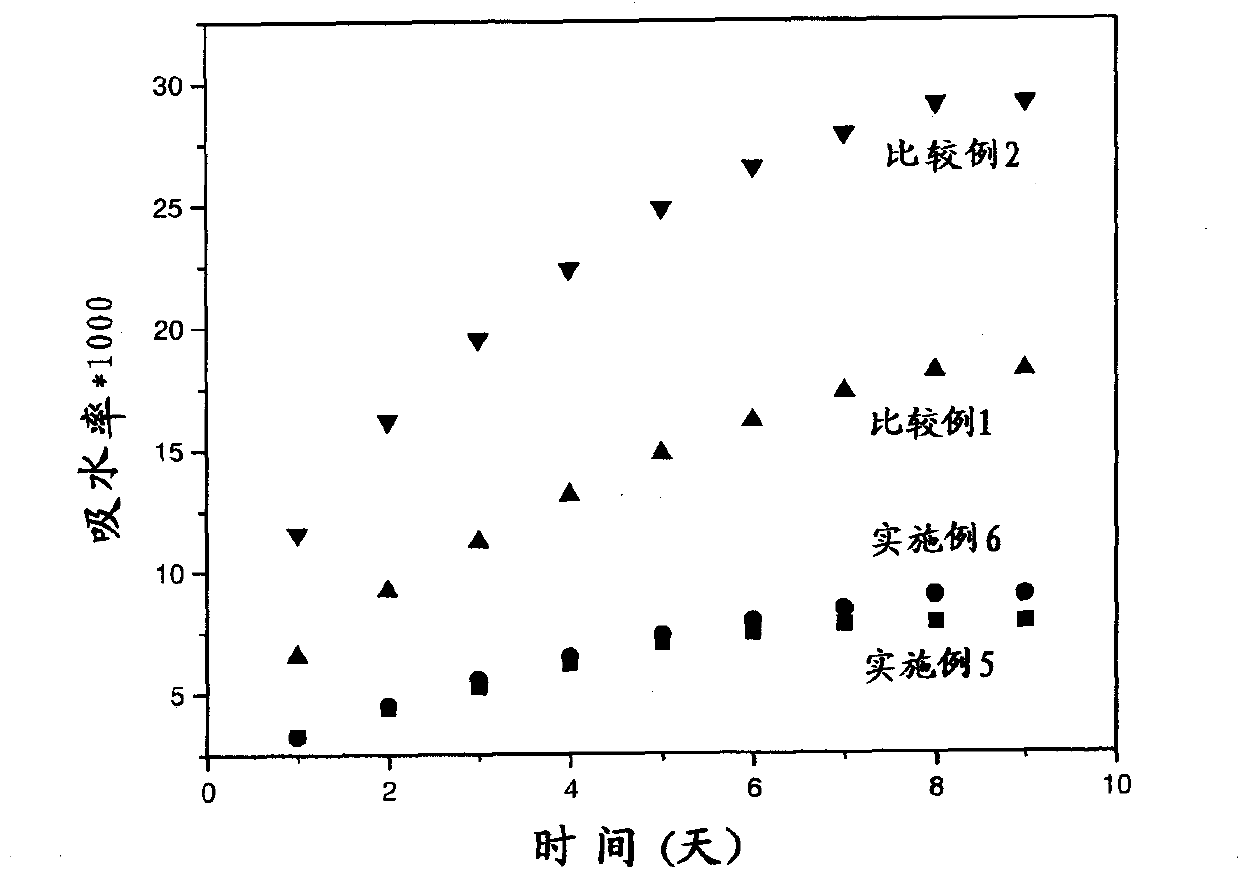

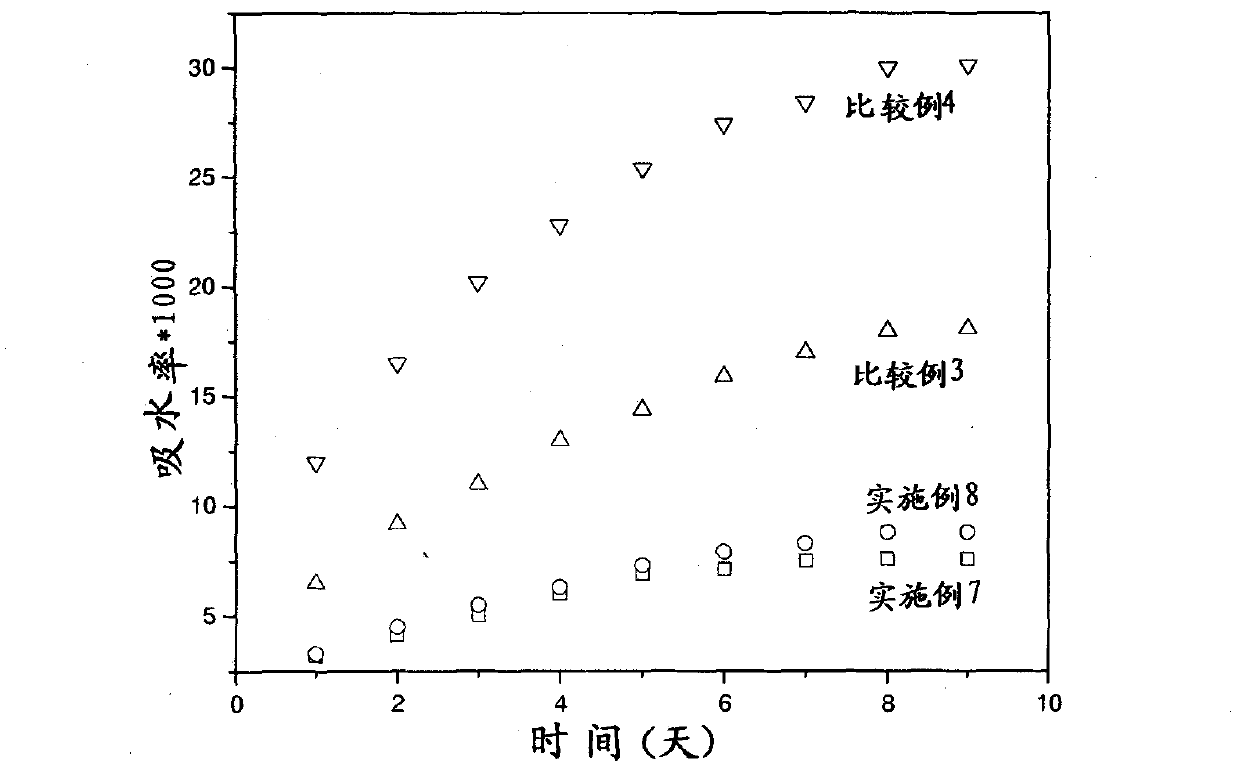

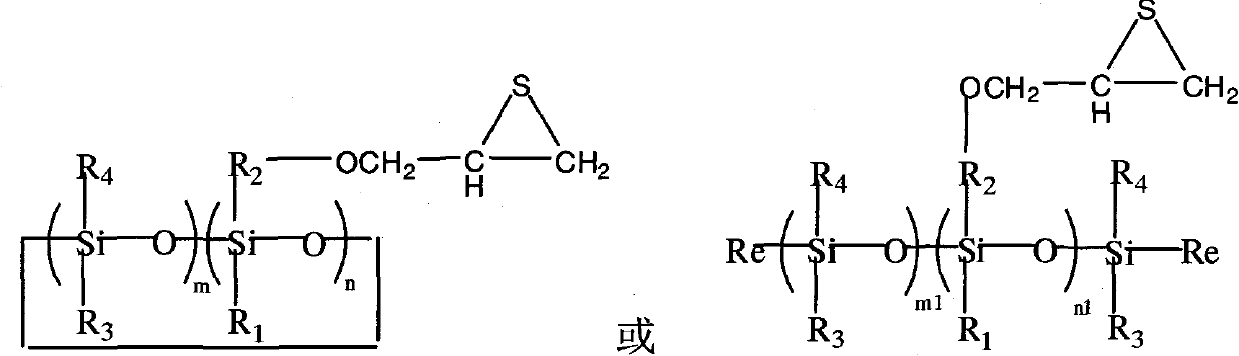

A technology of episulfide resin and silicon epoxy resin, which is applied in the direction of silicon organic compounds, can solve the problems of macroscopic phase separation and inability to achieve modification, and achieve the effects of high refractive index, high curing reactivity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add allyl glycidyl ether (35.7 grams, 0.31mol), toluene 50ml and 10ppm (in total weight of the reactant) chloroplatinic acid catalyst in a 250ml three-necked flask equipped with mechanical stirring, condenser and thermometer. The temperature of the above reaction mixture was raised to 70° C., (15 g, 0.0625 mol) octamethyltetrahydrocyclotetrasiloxane was added dropwise within 30 minutes, and the reaction was continued for 4 hours after the dropwise addition was completed. After the reaction was completed, the toluene solvent and unreacted reactants were removed with a rotary evaporator at 2mmHg / 80°C to obtain 41.5 grams of colorless and transparent silicone epoxy resin A with the following structural formula, and the yield was about 95.4%. The refractive index is 1.46.

[0028]

[0029] In a 100ml there-necked flask equipped with mechanical stirring and a thermometer, add the above-mentioned organosilicon epoxy resin A (8.7 grams, 0.0125mol), potassium thiocyanate (KS...

Embodiment 2

[0033] Add allyl glycidyl ether (14.4 grams, 0.125mol), toluene 50ml and 10ppm (in total weight of the reactant) chloroplatinic acid catalyst in a 250ml three-necked flask equipped with mechanical stirring, condenser and thermometer. The temperature of the resulting reaction solution was raised to 70° C., and (15 g, 0.0625 mol) octamethyltetrahydrocyclotetrasiloxane was added dropwise within 30 minutes, and the reaction was continued for 4 hours after the dropwise addition was completed. After the reaction was completed, the toluene solvent and unreacted reactants were removed with a rotary evaporator at 2mmHg / 80°C to obtain 28.1 grams of colorless and transparent silicone epoxy resin B with the following structural formula, and the yield was about 95.6%. The product The refractive index is 1.44.

[0034]

[0035] Add the organosilicon epoxy resin B (5.68 grams, 0.0125mol), potassium thiocyanate (KSCN) (2.43 grams, 0.05mol) (2.43 grams, 0.05mol), deionized water 10ml and Eth...

Embodiment 3

[0039] Add allyl glycidyl ether (35.7 grams, 0.31mol), toluene 50ml and 10ppm (in total weight of the reactant) chloroplatinic acid catalyst in a 250ml three-necked flask equipped with mechanical stirring, condenser and thermometer. The temperature of the resulting reaction solution was raised to 70° C., and (15 g, 0.112 mol) tetramethyldihydrodisiloxane was added dropwise within 30 minutes, and the reaction was continued for 4 hours after the dropwise addition was completed. After the reaction was completed, the toluene solvent and unreacted reactants were removed with a rotary evaporator at 2mmHg / 80°C to obtain 38.74 grams of colorless and transparent silicone epoxy resin C with the following structural formula, and the yield was about 95.6%. The refractive index is 1.45.

[0040]

[0041] Add the silicone epoxy resin C (9.05 grams, 0.025mol), potassium thiocyanate (KSCN) (14.58 grams, 0.15mol) and 40ml of deionized water obtained above in a 100ml three-necked flask equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com