Hydraulic control system for rotation system of horizontal directional drilling machine

A technology of hydraulic control system and horizontal directional drilling rig, which is applied to the automatic control system of drilling, rotary drilling, rotary drilling rig, etc., can solve the problems of insufficient power, suction of hydraulic motor, excessive pressure loss of manual slide valve, etc. , to achieve the effect of convenient operation, small pressure loss and solving power shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

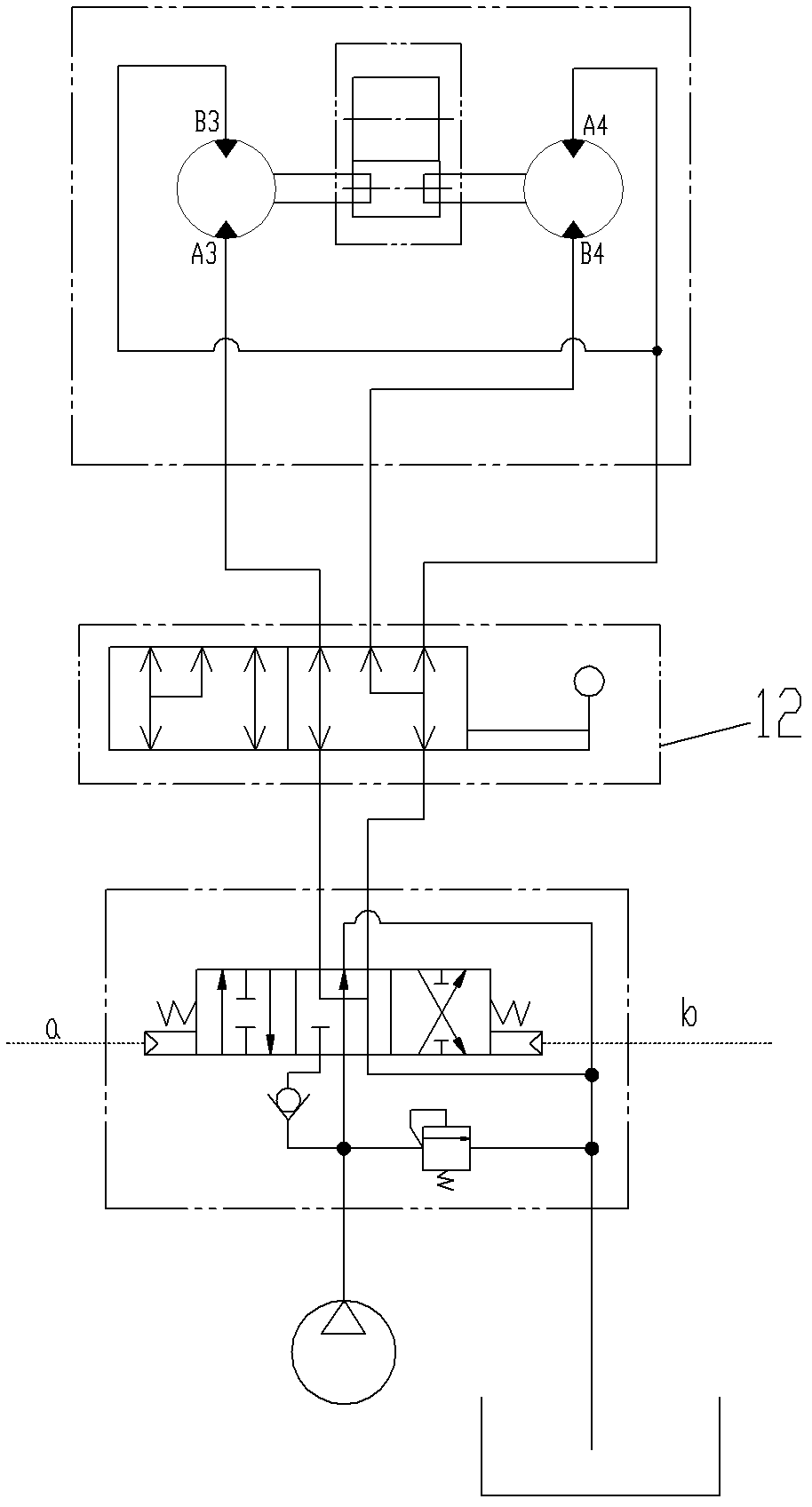

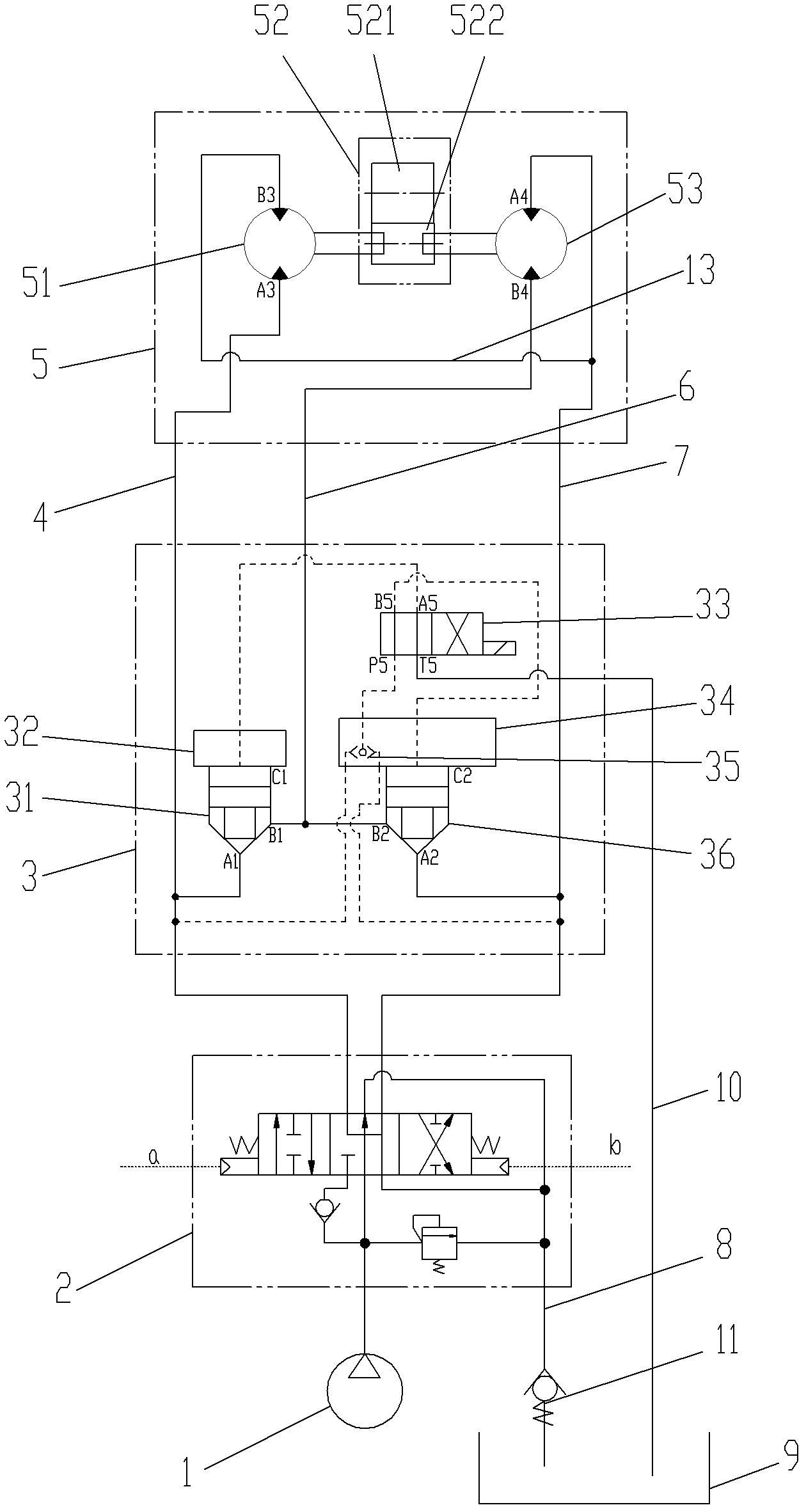

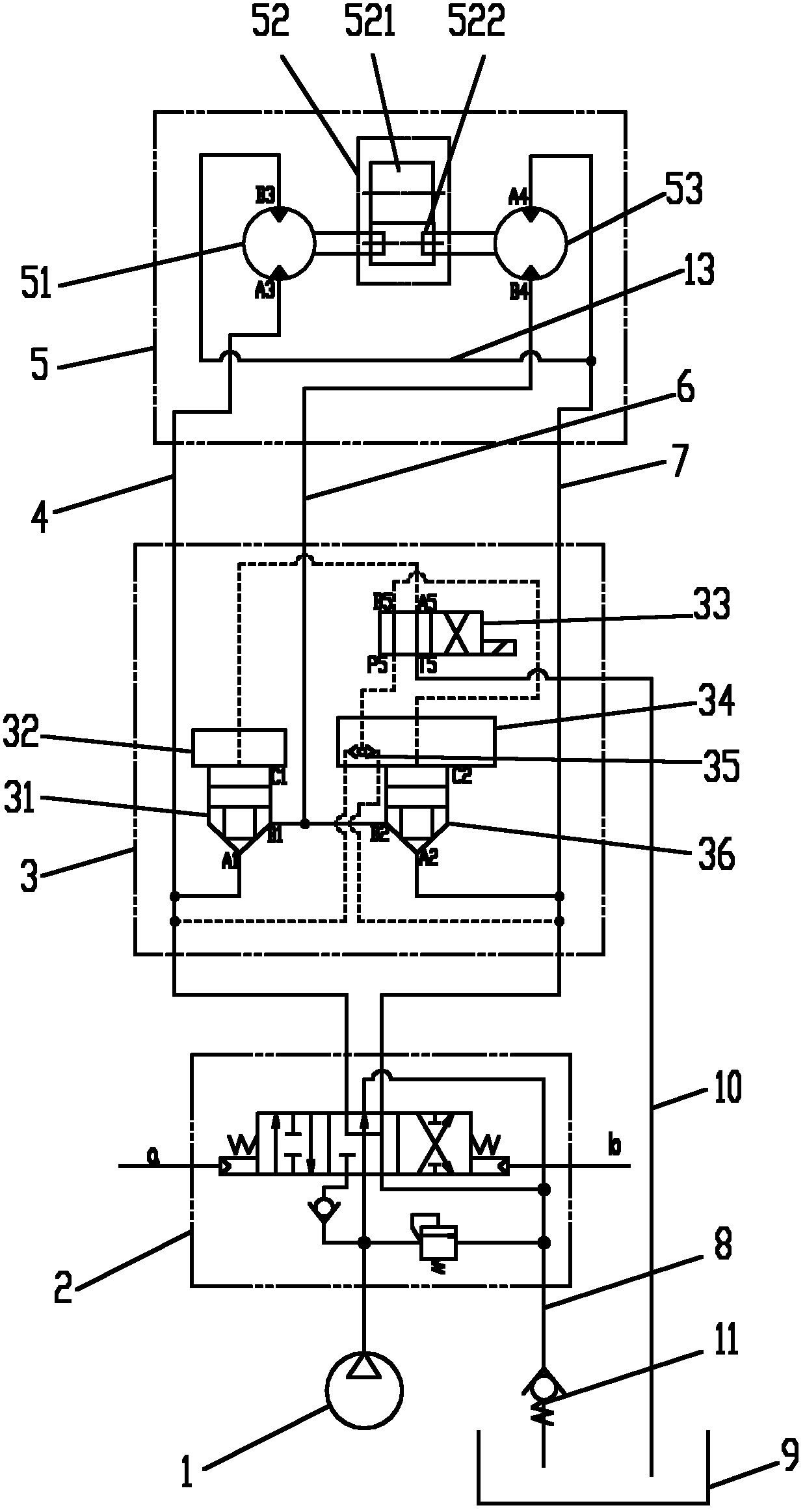

[0019] Such as figure 2 As shown, the hydraulic control system of the rotary system of the horizontal directional drilling rig of the present invention includes a main pump 1 , a main control valve 2 , a two-speed valve device, and a power head assembly 5 . (In order to distinguish the oil port or oil passage of each component, in this embodiment, numbers are added after the code of the corresponding oil port or oil passage for distinction.)

[0020] The power head assembly 5 mainly includes the hydraulic motor I53, the hydraulic motor II51 and the reducer assembly. The reducer assembly mainly includes the input gear 522 and the output gear 521. The output shafts of the hydraulic motor I53 and the hydraulic motor II51 are connected in series through the input gear 522. After the hydraulic motor I 53 and the hydraulic motor II 51 rotate, they drive the input gear 522 to rotate, and the input gear 522 drives the output gear 521 to complete the final rotation of the power head. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com