White light LED (Light Emitting Diode) device and manufacturing method thereof

A LED device and LED chip technology, applied in the field of lighting, can solve the problems of high cost, uneven glue distribution, poor stability, etc., and achieve the effect of convenient manufacturing process, simple structure, and adjustable color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

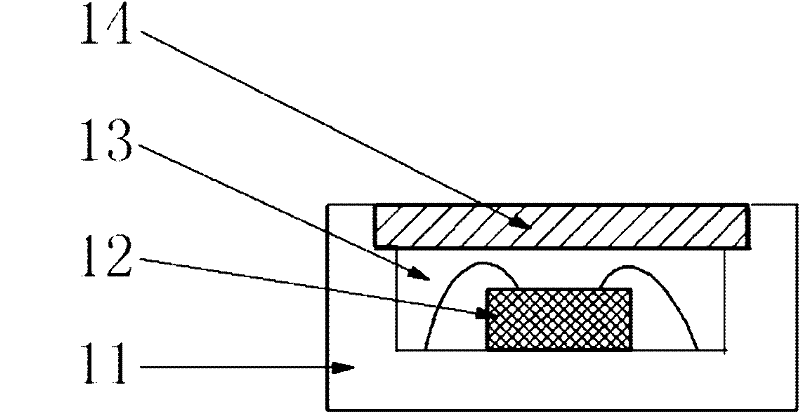

[0031] Embodiment 1: as figure 1 , a white LED device, comprising a substrate 11, the substrate is an aluminum substrate, the substrate 11 is concave, cylindrical, a blue LED chip 12 is fixed on the inner bottom surface of the concave substrate 11, the inner bottom surface of the substrate 11 and its inner side Reflective treatment is done on the wall to reflect light and increase light utilization efficiency, for example, a reflective film is provided on the surface of the substrate 11 . A quantum dot composite luminescent material plate 14 is arranged above the blue LED chip 12 , and a transparent packaging material 13 is filled between the blue LED chip 12 and the quantum dot composite luminescent material plate 14 . The quantum dot composite luminescent material plate 14 is nano-microporous glass uniformly dispersed with luminescent quantum dots, and the nano-microporous glass is wrapped with light-transmitting epoxy resin, and the entire outer surface of the nano-micropor...

Embodiment 2

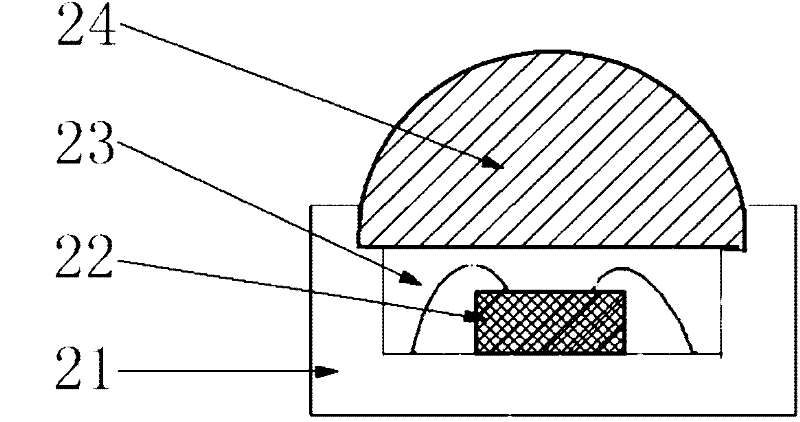

[0037] Embodiment 2: as figure 2 A single blue LED chip 22 is fixed on the concave bottom surface of the aluminum substrate 21, a quantum dot composite luminescent material plate 24 is arranged above the blue LED chip 22, and transparent Encapsulation material 23. The quantum dot composite luminescent material plate 24 is nano-microporous glass uniformly dispersed with yellow-light and red-light luminescent quantum dots, and the nano-microporous glass is protected by light-transmitting silica gel. The particle size of the luminescent quantum dots in this embodiment is 3-5 nm. The quantum dot composite luminescent material plate 24 in this embodiment is a curved plate, specifically a hemispherical shape with a convex surface outward.

[0038] The manufacturing steps of the white light LED device are as follows: first, a single blue LED chip 22 is fixed on the concave bottom surface of the aluminum substrate 11, after the blue LED chip 22 is welded with gold wires, a transpar...

Embodiment 3

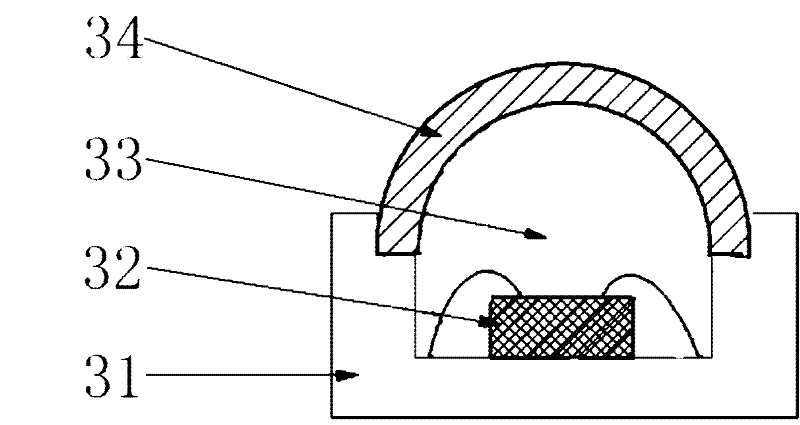

[0039] Embodiment 3: as image 3A single violet LED chip 32 is fixed on the concave bottom surface of the aluminum substrate 31, a quantum dot composite luminescent material plate 34 is arranged above the violet LED chip 32, and a transparent layer is filled between the violet LED chip 32 and the quantum dot composite luminescent material plate 34 Encapsulation material33. The quantum dot composite luminescent material plate 34 is nano-microporous glass uniformly dispersed with luminescent quantum dots emitting blue light, green light, and red light, and the nano-microporous glass is wrapped with light-transmitting polymethyl methacrylate Protect. The particle size of the luminescent quantum dots in this embodiment is 5-8 nm. The quantum dot composite luminescent material plate 34 in this embodiment is a curved plate, specifically a convex arc plate with equal wall thickness. The curved panel is preferred, so that the light emitted from the white LED device is more concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com