Air electrode material of double template porous channel structure for lithium air battery and preparation method thereof

A lithium-air battery and air electrode technology, which is applied to battery electrodes, structural parts, circuits, etc., can solve the problems of reducing the utilization rate of air electrode pores, reducing cycle performance and rate performance, and air electrode blockage, etc., to achieve good electrochemical cycle Stability, simple and easy preparation method, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

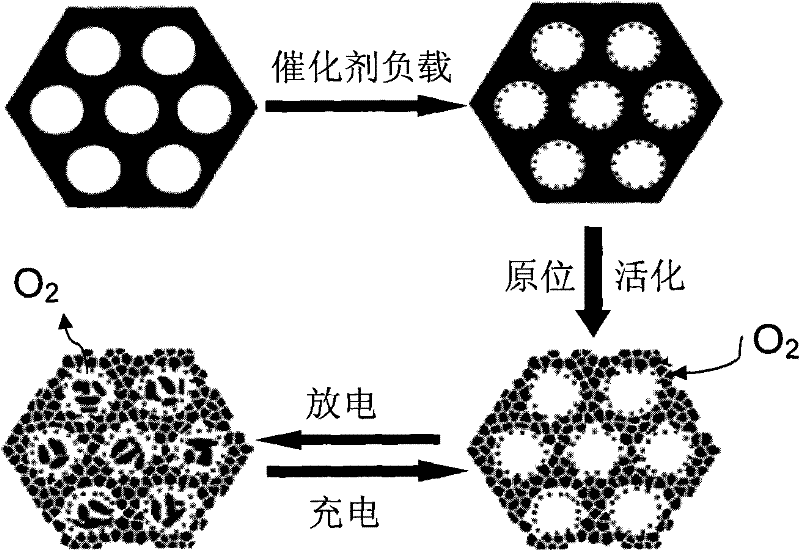

[0036] The preparation method of the dual-mode channel structure air electrode material of the present invention, the method comprises the following steps:

[0037] (1) supporting catalysts in situ on the surface of the porous carrier;

[0038] (2) Carry out in-situ activation treatment of the pores on the porous carrier after loading the catalyst;

[0039] (3) Uniformly mixing the porous carrier obtained in (2) with the binder to form a dual-mode porous structure air electrode material, and the mass ratio of the porous carrier to the binder is 1:1˜10:1.

[0040] The in-situ loading of the catalyst on the surface of the porous carrier includes in-situ chemical reaction deposition on the surface of the porous carrier, impregnation, electroplating deposition, physical vapor deposition or a combination thereof. The thickness of the catalyst on the surface of the porous carrier is 0.5-50nm, and the size of the porous carrier is 50nm-1000nm.

[0041]The in-situ activation treatme...

Embodiment 1

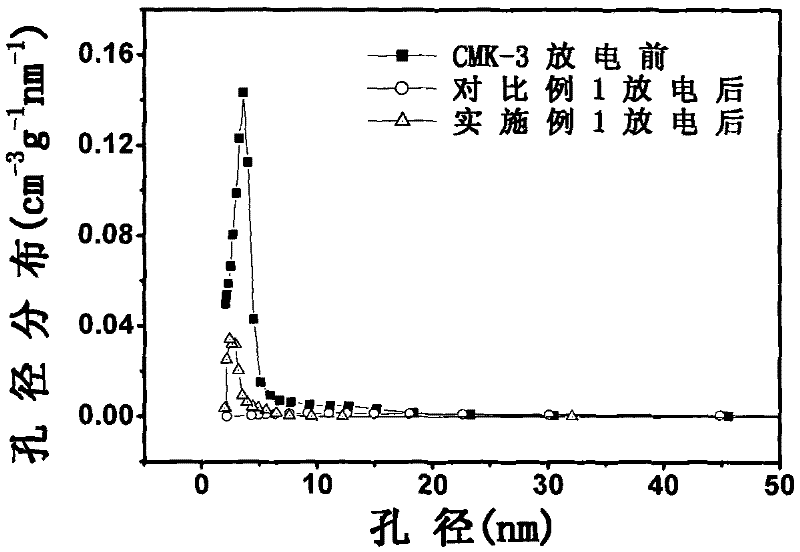

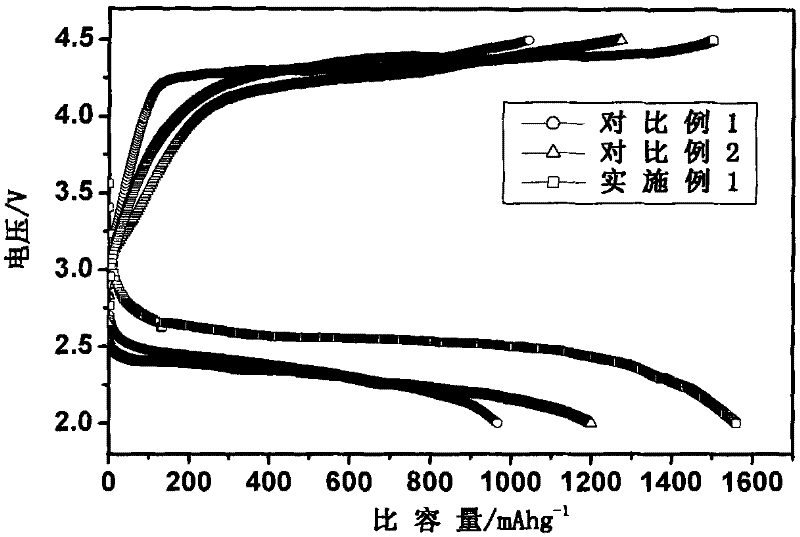

[0056] ①Catalyst loading: first take 1g of dry ordered mesoporous carbon CMK-3, and use the same catalyst loading method as in Comparative Example 2 to obtain MnO 2 @CMK-3 carrier; ② in situ activation: take 0.4g of MnO 2 @CMK-3, add 0.4g KOH and 4ml distilled water, evaporate the water to dryness at 100°C, then transfer to nickel crucible, tube furnace N 2 Under atmosphere, heat up to 750°C at a heating rate of 2°C / min, keep at 750°C for 1 h, wash with 2mol / L HCl at room temperature, then wash with water until neutral, and finally dry the mixture in vacuum at 100°C, and mix with poly The mass ratio of vinylidene fluoride (PVDF) 9:1 prepares air electrode by the mode of comparative example 1, assembles with comparative example 1, in the voltage range of 2-4.5V, 0.1mA / cm 2 The charge-discharge test was carried out at the current density. The obtained test results are shown in Table 1. From the data in Table 1, it can be seen that compared with Comparative Example 1 and Compa...

Embodiment 2

[0058] ① Catalyst loading: First, 1 g of dry ordered mesoporous carbon CMK-3 was immersed in 4.6 mol / L Co(NO 3 ) 2 In 50ml ethanol solution, magnetically stirred for 30min, then centrifuged at 2950r / min for 30min, dried in vacuum at room temperature for 24h, and then treated at 573K for 4h, obtained by impregnation method. 3 o 4 @CMK-3 carrier; ② in situ activation: take 0.4g of Co 3 o 4 @CMK-3, add 0.4g KOH and 4ml distilled water, evaporate the water to dryness at 100°C, then transfer to nickel crucible, tube furnace N 2 Under atmosphere, heat up to 750°C at a heating rate of 2°C / min, keep at 750°C for 1 h, wash with 2mol / L HCl at room temperature, then wash with water until neutral, and finally dry the mixture in vacuum at 100°C. There is no catalyst in the new pores due to activation, that is, the Co 3 o 4 Air electrode material with double-mode pore structure as catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com