Three-layered composite chitin non-woven fabric, and preparation method and application thereof

A layer-composite, chitin technology, used in textiles and papermaking, chemical instruments and methods, non-woven fabrics, etc., can solve the problems of increasing patient pain, adhesion, and easy adhesion, and achieve excellent breathability, moisture retention, and softness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

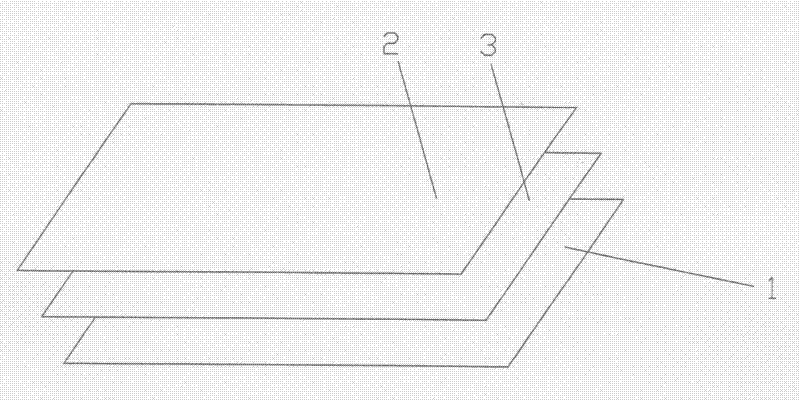

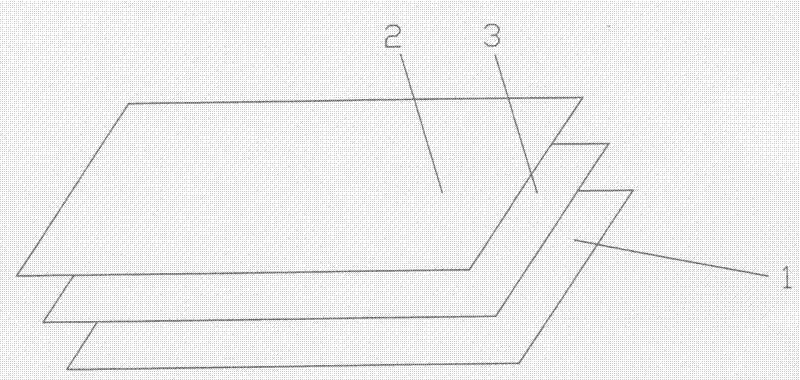

[0026] please see figure 1 , figure 1 The chitin three-layer composite non-woven fabric is composed of chitin fiber cloth layer 1, ES fiber cloth layer 2 and viscose fiber cloth layer 3 between chitin fiber cloth layer 1 and ES fiber cloth layer 2. Chitin The fiber cloth layer 1, the ES fiber cloth layer 2 and the viscose fiber cloth layer 3 are bonded together by a needle punching machine commonly used in the non-woven machinery industry. The ES of the ES fiber cloth layer 2 mentioned here is the abbreviation of the English full name "Ethylene-Propylene Side By Side". ES fiber is a kind of polyolefin fiber developed by Japan Zhiso Company. composite fiber. ES fiber is a composite fiber with a two-component skin-core structure. The cortex has a low melting point and excellent flexibility, while the core has a high melting point, high strength, excellent liquid absorption, and good water repellency. The three-layer composite of chitin The preparation method of non-woven fabr...

Embodiment 2

[0033] Only change the fineness and length of the chitin fiber in step A) to 2.5dtex and 45mm respectively, change the grammage of the chitin fiber cloth layer 1 to 30g / ㎡, and change the needling speed to 60 times / min; Change the fineness and length of the ES fiber in step B) to 1.6dtex and 60mm respectively, and change the grammage of ES fiber cloth layer 2 to 50g / ㎡; only change the fineness and length of the viscose fiber in step C) to 3.0dtex and 45㎜, the weight of the viscose fiber cloth layer 3 was changed to 200g / ㎡; the speed of the needle punching machine was changed to 400 times / min, and a chitin three-layer composite with a total weight of 280g / ㎡ was obtained. Non-woven fabric, all the other are with the description to embodiment 1.

Embodiment 3

[0035] Only change the fineness and length of the chitin fiber in step A) to 3.0dtex and 50mm respectively, change the grammage of the chitin fiber cloth layer 1 to 40g / ㎡, and change the needling speed to 80 times / min; Change the fineness and length of the ES fiber in step B) to 2.5dtex and 40mm respectively, and change the grammage of the ES fiber cloth layer 2 to 60g / ㎡; only change the fineness and length of the viscose fiber in step C) to 2.0dtex and 60㎜, the weight of the viscose fiber cloth layer 3 is changed to 210g / ㎡; the speed of the acupuncture machine is changed to 500 times / min, and the chitin three-layer composite with a total weight of 310g / ㎡ is obtained Non-woven fabric, all the other are with the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com