Special fireproof paint for hard polyurethane foam (PUF) thermal insulation material and preparation method thereof

A foam insulation material and rigid polyurethane technology, applied in fireproof coatings, epoxy resin coatings, coatings, etc., can solve the problems of fast speed, large smoke volume, ignition, etc., achieve high thermal stability and prolong flame resistance time , Strong effect of moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Melt 20-30 parts of modified high-chlorinated polyethylene with 2-3 parts of butyl acetate to form a 30% solution under high-speed stirring, and mix 10-15 parts of internal vinyl acid resin and 4-5 parts of 50% epoxy resin Add 1-2 parts of organic expansive soil into the solution under low-speed stirring, and stir for about ten minutes; then add 2-5 parts of melamine, 6-10 parts of pentaerythritol, 6-10 parts of zinc aluminate, 13-15 parts Ammonium polyphosphate, 2-6 parts of chlorinated paraffin, 2-6 parts of titanium dioxide, 4-8 parts of flame retardant, etc., after stirring for 30 minutes, send them to the grinder for grinding, and stop grinding after the detection fineness reaches 90μm; Next, add 1-2 parts of defoamer, and add all the remaining 8-12 parts of xylene and stir evenly.

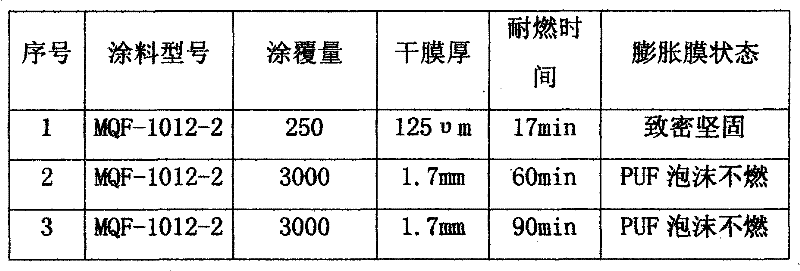

[0007] After the preparation was successfully prepared, several flame resistance tests were carried out. A set of test data is shown below:

[0008] Data 1 was inspected by Beijing Bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com