Water-borne adhesive used for steel plate flocking and its preparation method

A water-based, adhesive technology, applied in the direction of adhesives, adhesive types, graft polymer adhesives, etc., can solve the problems of insufficient bonding fastness, waterproof performance and poor aging resistance, etc. To achieve the effect of lasting bond strength and other properties, ensure bond strength and other properties, and moderate flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

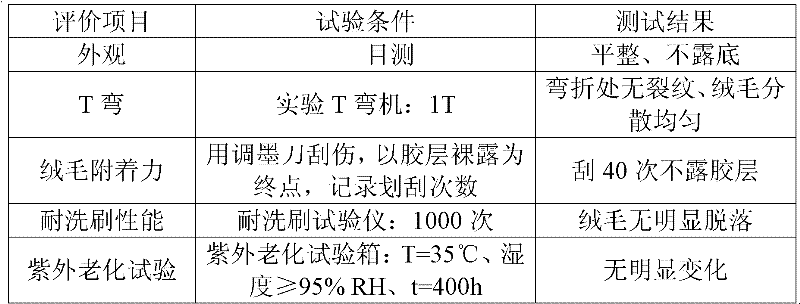

Examples

Embodiment 1

[0026] Example 1: A preparation method of a water-based adhesive for flocking steel plate, which is prepared by the following steps, and its component ratio is calculated in parts by weight:

[0027] (1) Preparation of polyurethane prepolymer: 150 parts of polyester polyol, 45 parts of isophorone diisocyanate and 0.01 parts of catalyst are mixed and stirred and heated to 75°C, reacted for 2 hours, and the stirring speed is 1000 rpm; cooling down; To 65°C, add 6 parts of dimethylolpropionic acid and 5 parts of N-methylpyrrolidone, and react for 4 hours at a temperature of 65°C and stirring speed of 1000 rpm; cool to 30°C and add 5 parts of three Ethylamine, react for 30 minutes at a stirring speed of 1000 rpm; then add 300 parts of deionized water, disperse and emulsify at a high speed for 1 hour at a stirring speed of 2000 rpm; finally add 4 parts of isophor The ketone diamine is reacted for 60 minutes at a stirring speed of 1000 revolutions per minute to obtain a polyurethane pr...

Embodiment 2

[0034] Example 2: A preparation method of a water-based adhesive for steel plate flocking, which is prepared by the following steps, and its component ratio is calculated in parts by weight:

[0035] (1) Preparation of polyurethane prepolymer: 250 parts of polyester polyol, 80 parts of isophorone diisocyanate and 0.1 part of catalyst are mixed and stirred and heated to 85°C, reacted for 1.5 hours, and the stirring speed is 1500 rpm; cooling down To 70°C, add 10 parts of dimethylolpropionic acid and 9 parts of N-methylpyrrolidone, and react for 3.5 hours at a temperature of 75°C and a stirring speed of 1500 rpm; cool to 40°C and add 8 parts of three Ethylamine, react for 10 minutes at a stirring speed of 1500 rpm; then add 600 parts of deionized water, disperse and emulsify at a high speed for 0.5 hours at a stirring speed of 3500 rpm; finally add 10 parts of isophor Ketone diamine reacted for 30 minutes at a stirring speed of 1500 rpm to obtain a polyurethane prepolymer; the cata...

Embodiment 3

[0039] Example 3: A preparation method of a water-based adhesive for steel plate flocking, prepared by the following steps, and its component ratios are calculated in parts by weight:

[0040] (1) Preparation of polyurethane prepolymer: Mix 200 parts of polyester polyol, 60 parts of isophorone diisocyanate and 0.05 parts of catalyst, stir and heat to 80°C, react for 1.8 hours, and stir at 1200 revolutions per minute; cooling down To 68°C, add 8 parts of dimethylolpropionic acid and 7 parts of N-methylpyrrolidone, and react for 3.8 hours at a temperature of 70°C and a stirring speed of 1200 rpm; cool to 35°C and add 6 parts of three Ethylamine, react for 20 minutes at a stirring speed of 1200 rpm; then add 500 parts of deionized water, disperse and emulsify at a high speed for 0.8 hours at a stirring speed of 3000 rpm; finally add 6 parts of isophor The ketone diamine is reacted for 50 minutes at a stirring speed of 1200 rpm to obtain a polyurethane prepolymer; the catalyst is dib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com