Multistage series-connection gasifier chamber structure

A furnace structure and gasifier technology, which are used in the gasification of granular/powder fuel, the manufacture of combustible gas, the petroleum industry, etc. Problems such as low space utilization rate of gasification furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

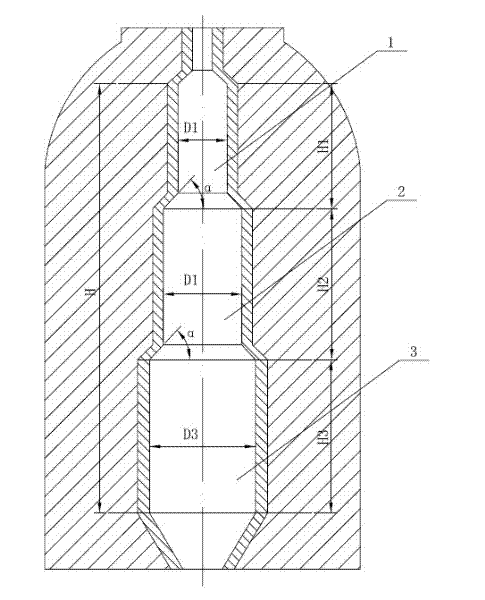

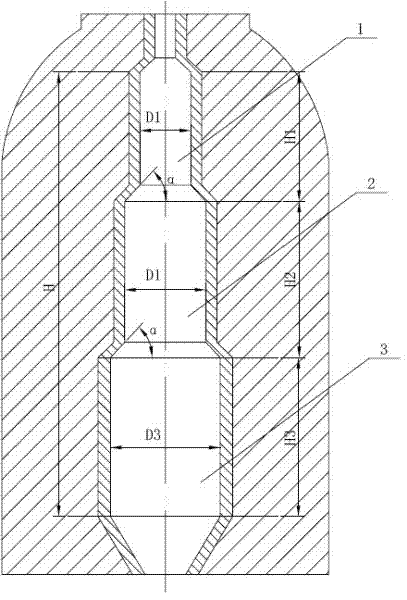

[0020] Such as figure 1 As shown, the furnace structure of the multi-stage series gasifier includes the first-stage furnace 1, the second-stage furnace 2 and the third-stage furnace 3 connected in sequence in the longitudinal direction, and the first-stage furnace 1, the second-stage furnace 2 and the third-stage furnace The three-stage furnaces 3 are all hollow cylinders, and the first-stage furnace 1, the second-stage furnace 2 and the third-stage furnace 3 are connected by a hollow frustum of cone.

[0021] The first-stage furnace 1 is located at the upper end with a diameter of D 1 , with height H 1 ;The second-stage furnace 2 is located in the middle, with a diameter of D 2 , with height H 2 ; The third stage furnace 3 is located at the lower end, with a diameter of D 3 , with height H 3 ; The total height of the three-stage furnace is H, that is, H=H 1 +H 2 +H 3 .

[0022] And the three-stage hearth is satisfied: D 1 2 3 , 01 2 3 <H.

[0023] The diameter D of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com