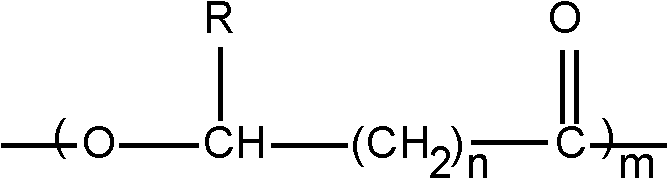

Method for preparing polyhydroxybutyrate (PHB)

A technology of polyhydroxybutyrate and seeds is applied in the field of preparing PHB by copper bacteria strain sh-1, which can solve the problems of low economic benefit and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

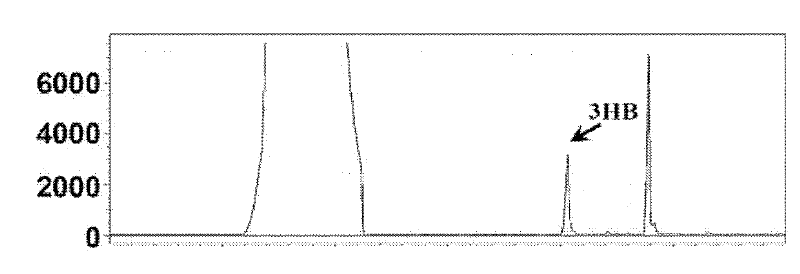

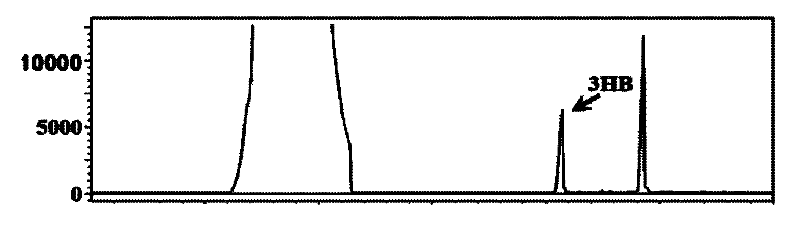

Image

Examples

Embodiment 1

[0068] The formula of culture medium used in the present embodiment is:

[0069] Incline medium: yeast extract 10g / L, peptone 10g / L, (NH 4 ) 2 SO 4 5g / L, agar 15g / L, pH7.

[0070] Seed medium: yeast extract 10g / L, peptone 10g / L, (NH 4 ) 2 SO 4 5g / L, pH7.

[0071] Fermentation medium: Na 2 HPO 4 ·7H 2 O 2g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 0.2g / L, ferric ammonium citrate 50mg / L, CaCl 2 2H 2 O 10mg / L, (NH 4 ) 2 SO 4 2g / L, glucose 60g / L, pH7.

[0072] 1. Production of PHB:

[0073] a. Inoculate the strains on the slant medium and culture at 30°C for 24h;

[0074] b. Inoculate a ring of well-grown slant culture into a 500mL Erlenmeyer flask containing 100mL seed medium, shake the flask at a rotational speed of 180r / min, and culture at 30°C for 24h;

[0075] c. Insert 10% of the inoculum into the fermentation medium, the capacity of the fermenter is 2L, the liquid volume is 1.5L, the stirring speed in the fermenter is 400r / min, the ventilation rate is 100L / min...

Embodiment 2

[0089] The formula of culture medium used in the present embodiment is:

[0090] Incline medium: yeast extract 10g / L, peptone 10g / L, (NH 4 ) 2 SO 4 5g / L, agar 15g / L, pH7.

[0091] Seed medium: yeast extract 10g / L, peptone 10g / L, (NH 4 ) 2 SO 4 5g / L, pH7.

[0092] Fermentation medium: Na 2 HPO 4 ·7H 2 O 6g / L, KH 2 PO 4 4g / L, MgSO 4 ·7H 2 O 0.5g / L, ferric ammonium citrate 75mg / L, CaCl 2 2H 2 O 25mg / L, (NH 4 ) 2 SO 4 7g / L, glucose 100g / L, pH7.

[0093] 1. Production of PHB:

[0094] a. Inoculate the strains on the slant medium and culture at 30°C for 24h;

[0095] b. Inoculate a ring of well-grown slant culture into a 500mL Erlenmeyer flask containing 100mL seed medium, shake the flask at a rotational speed of 180r / min, and culture at 30°C for 24h;

[0096] c. Insert 10% of the inoculum into the fermentation medium, the capacity of the fermenter is 2L, the liquid volume is 1.5L, the stirring speed in the fermenter is 400r / min, the ventilation rate is 180L / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com