Preparation method of sodium alginate immobilized bacterial combination for polycyclic aromatic hydrocarbon pollution remediation

A technology of sodium alginate and combined bacteria, which is applied in the field of biological treatment of environmental pollutants, and can solve problems such as poor adaptability of single strains and secondary pollution of bacterial groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

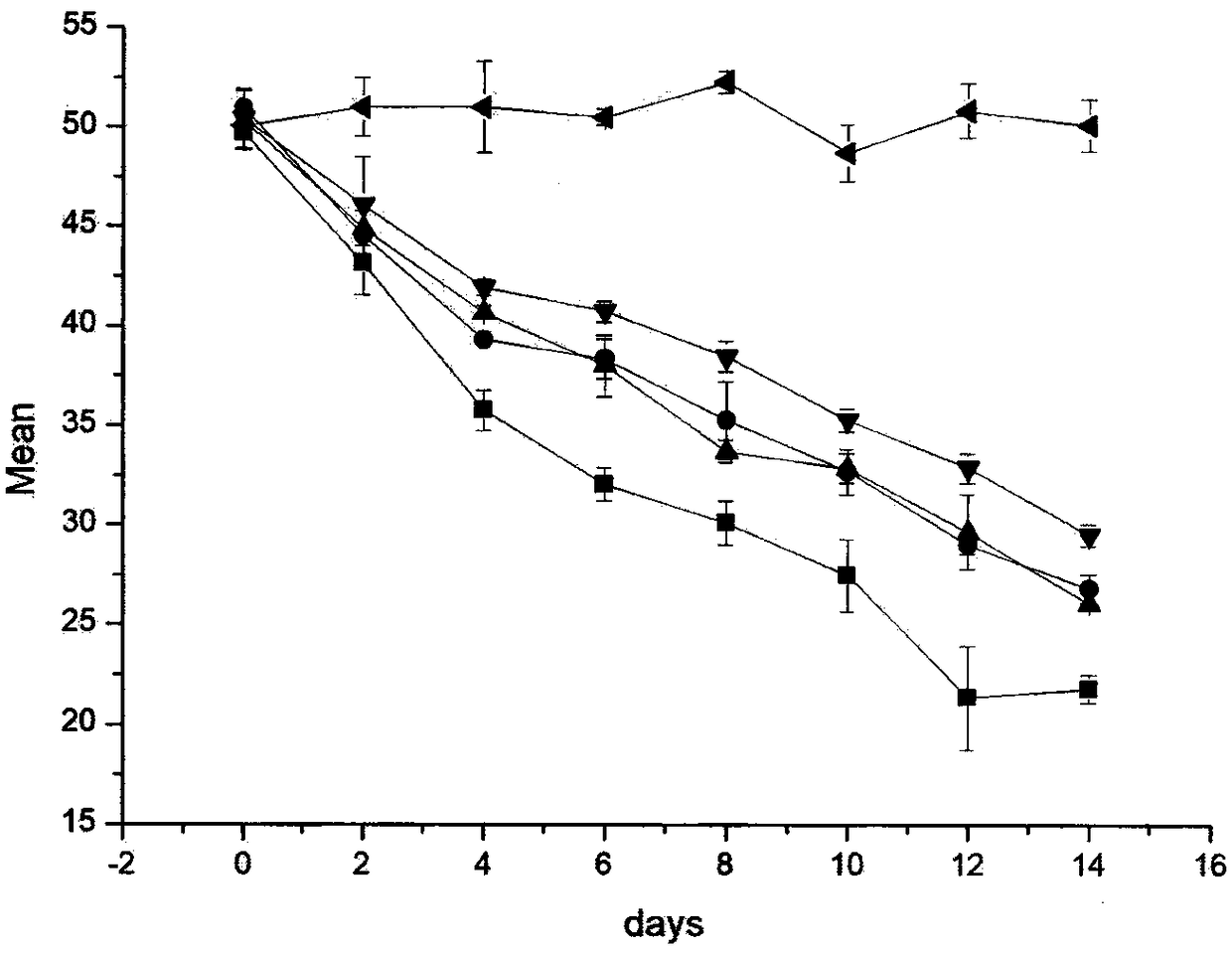

[0053] Example 1: Comparison of the degradation effects of different proportions of free combined flora on benzo[a]pyrene

[0054] According to the differences in the degradation ability and growth rate of the 8 strains to benzo[a]pyrene, the 8 strains were divided into two groups, P6 and P7 were the main degrading bacteria, and the other 6 strains were secondary degrading bacteria.

[0055] Take the culture fluid of the 8 strains that have been subcultured for 48 hours and adjust the OD600 to 0.120. The equal volumes of the culture fluids of P6 and P7 were mixed as the inoculum of the main degrading bacteria; The two kinds of inoculums were mixed according to main degrading bacteria: secondary degrading bacteria = 1:0, 9:1, 4:1 and 3:2 respectively as the inoculation solutions of combinations 1-4. Add 0.2mL benzo[a]pyrene-acetone stock solution to a 15mL brown sample bottle, blow nitrogen to dryness, add 1.8mL inorganic salt liquid medium and 0.2mL bacterial inoculum, cultiv...

Embodiment 2

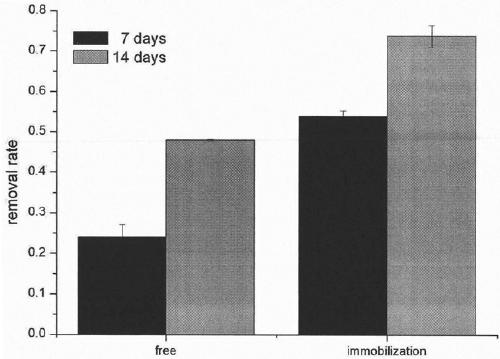

[0057] Example 2: Comparison of the degradation effects of the free combined flora and the sodium alginate immobilized combined flora on the degradation of benzo[a]pyrene

[0058] The strain P4 was inoculated in the R2A liquid medium, and the remaining 7 strains were inoculated in the glucose-inorganic salt liquid medium, and immobilized after culturing in a shaker at 28°C and 160 rpm for about 48 hours. In the ultra-clean workbench, add an equal volume of 4% sodium alginate solution to the bacterial solution of the 8 strains, stir slowly until the bacterial solution is uniform, use a sterile syringe to draw and inject 4% CaCl drop by drop 2 In the solution, let it stand for 5-10 minutes for hardening treatment, remove the pellet, wash it with sterile saline for 3 times, put it into a ground vial, and place it in a refrigerator at 4°C for later use. During this process, except for the sterilizing solution and sterile syringes, other supplies must be autoclaved at 121°C for 30 ...

Embodiment 3

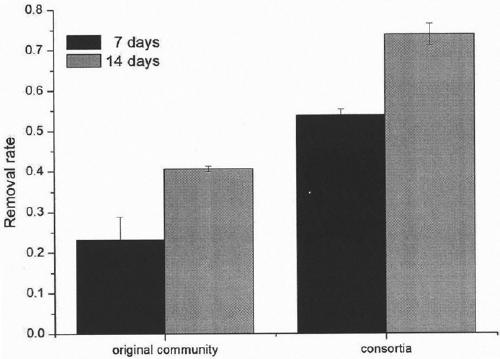

[0061] Example 3: Comparison of the degradation effects of immobilized original flora and combined flora on benzo[a]pyrene

[0062] Weigh 5 g of fresh sediment into 50 mL of inorganic salt liquid medium containing benzo[a]pyrene (concentration: 10 mg / L), and enrich culture at 25 degrees Celsius and 180 rpm on a shaking table for 7 days. After several subcultures, the concentration of benzo[a]pyrene was increased to 50mg / L, so that the polycyclic aromatic hydrocarbon degrading functional bacteria were enriched, and the original flora was obtained.

[0063] In the ultra-clean workbench, add an equal volume of 4% sodium alginate solution to the original flora bacterial solution, stir slowly until the bacterial solution is uniform, use a sterile syringe to absorb and inject 4% CaCl drop by drop 2 In the solution, let it stand for 5-10 minutes for hardening treatment, remove the pellet, wash it with sterile saline for 3 times, put it into a ground vial, and place it in a refrigerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com