Method for producing ZnSO alloy film with adjustable sulfur-doped growth band gap

An alloy film, sulfur doping technology, applied in metal material coating process, ion implantation plating, coating and other directions, to achieve the effect of good repeatability and stability, good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Take zinc oxide with a purity of 99.99% and zinc sulfide powder with a purity of 99.99%, and the S molar content is 10%, and mix the mixed powder of ZnO and ZnS. After the mixture is uniform, the powder is hydraulically formed into a disc with a thickness of 3 mm and a diameter of 50 mm at high temperature to obtain a target.

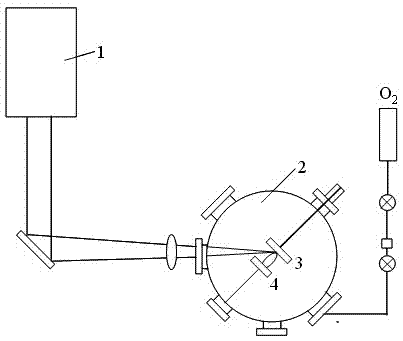

[0019] 2) Using quartz as the substrate, clean the surface of the substrate and put it into the growth chamber of the pulsed laser deposition device. -4 Pa, and then heated the substrate so that the substrate temperature was 300 °C, with ZnS-doped ZnO as the target, the distance between the substrate and the target was adjusted to 4.5 cm, the laser frequency was 3 Hz, and the laser energy was 250 mJ. The time is 30 minutes. After growth, it was cooled to room temperature at a cooling rate of 3 ℃ / min to obtain S-doped ZnSO alloy films with tunable bandgap.

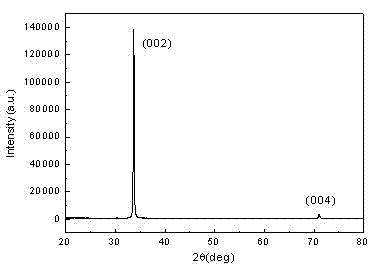

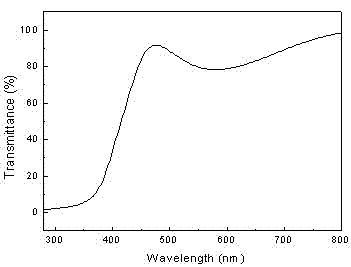

[0020] The obtained S-doped ZnSO alloy film with tunable bandgap has a forbidden ban...

Embodiment 2

[0022] 1) Take zinc oxide with a purity of 99.99% and zinc sulfide powder with a purity of 99.99%, and the S molar content is 30%, and mix the mixed powder of ZnO and ZnS. After the mixture is uniform, the powder is hydraulically formed into a disc with a thickness of 3 mm and a diameter of 50 mm at high temperature to obtain a target.

[0023] 2) Use quartz as the substrate, clean the surface of the substrate and put it into the growth chamber of the pulsed laser deposition device. -4 Pa, and then heated the substrate so that the substrate temperature was 400 °C, with ZnS-doped ZnO as the target, the distance between the substrate and the target was adjusted to 5 cm, the laser frequency was 5 Hz, and the laser energy was 300 mJ. The time is 30 minutes. After growth, it was cooled to room temperature at a cooling rate of 5 ℃ / min to obtain S-doped ZnSO alloy films with tunable bandgap.

[0024] The obtained S-doped ZnSO alloy thin film with tunable bandgap has a forbidden ba...

Embodiment 3

[0026] 1) Take zinc oxide with a purity of 99.99% and zinc sulfide powder with a purity of 99.99%, and the S molar content is 40%, and mix the mixed powder of ZnO and ZnS. After the mixture is uniform, the powder is hydraulically formed into a disc with a thickness of 3 mm and a diameter of 50 mm at high temperature to obtain a target.

[0027] 2) Using quartz as the substrate, clean the surface of the substrate and put it into the growth chamber of the pulsed laser deposition device. -3 Pa, and then heated the substrate so that the substrate temperature was 500 °C, with ZnS-doped ZnO as the target, the distance between the substrate and the target was adjusted to 5.5 cm, the laser frequency was 10 Hz, and the laser energy was 350 mJ. The grown The time is 30 minutes. After growth, it was cooled to room temperature at a cooling rate of 10 ℃ / min to obtain S-doped ZnSO alloy films with tunable bandgap.

[0028] The obtained S-doped ZnSO alloy film with tunable bandgap has a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap width | aaaaa | aaaaa |

| Bandgap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com