The existing so-called low-level cutting bed produced in China is simply to add a cutting knife to the paper pattern cutting machine, and the knife can be dropped at a fixed height through a servo motor. The fabric cannot be

cut, especially the large-format fabric cutting, and the scope of use is limited. It cannot be applied to industries such as large toy

inflatable models, membrane structures, and

rowing shipbuilding industries that urgently need low-level cutting machines. Only small-format cutting can be performed. , has little practical significance, and is not a low-level cutting bed in the true sense.

Most of the cutting heads in foreign low-level cutting machines have single functions, fewer types of knives, and no

red light preview function.

Cutting different fabrics requires cumbersome tool changes and adjustments. It is easy to

cut waste fabrics and waste fabrics. In addition, The pen used is also very special and cannot be replaced with an ordinary pen. After the ink is used up, it can only be replaced with a pen produced by a foreign original factory, which is very expensive to use

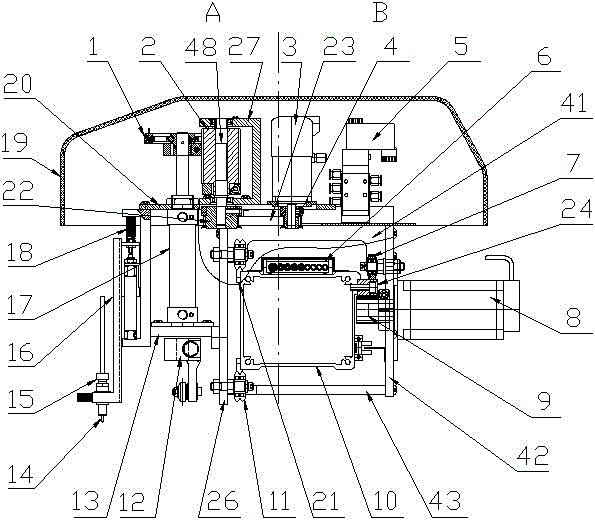

[0004] There are also some relatively good cutting heads used in the cutting bed at present, as disclosed on February 18, 2009, and the publication number is CN101367215 in the

Chinese patent, which discloses a cutting head for high-speed low-level cutting bed The cutting head for high-speed low-level cutting machine includes cutting head frame, pen, flat knife, pointed knife, round knife and

punching drill. The pen is set on the pen stand, which is connected to the vertical movement of the pen-down cylinder end, the fixed end of the pen-down cylinder is connected to the cutting head frame; The flat knife belt wheel on the cutting head frame is connected by splines; the sharp knife, round knife and flat knife are set in the same way; the

punching drill is set on the output shaft of the

punching air motor, and the punching air motor is set on the punching

drill base. The punching drill base is fixedly connected to the vertical moving end of the punching cylinder, and the fixed end of the punching cylinder is connected to the cutting head frame; among them, each cylinder is connected with the

solenoid valve, and each

pulley is connected with the rotary knife servo motor. , the

solenoid valve and rotary knife servo motor are set on the cutting head frame and connected with the

control circuit; the structural design of the cutting head is not reasonable enough, the whole is not simple and light enough, and the cutting head is not accurate in the cutting process

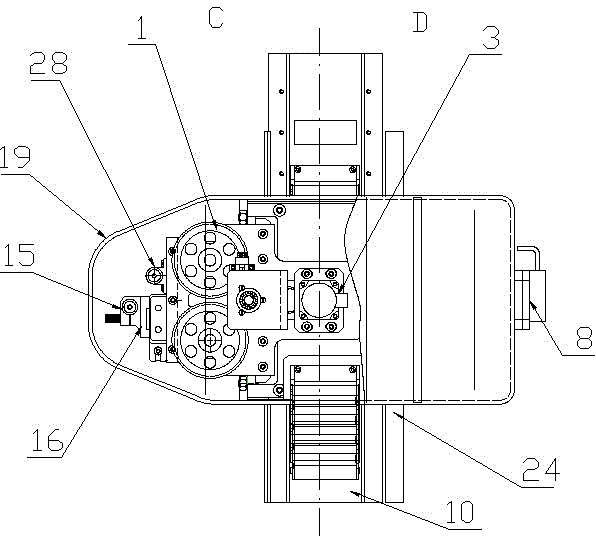

Another example is that the publication date is July 7, 1998, and the publication number is US5775189A, which discloses a cutting machine. The cutting machine includes a cutting frame. The knives are all set on the lower end of the

piston rod of the oil cylinder, the oil cylinder is fixed on the cutting frame, the upper end of the

piston rod is connected with the

pulley on the cutting frame, the cutting frame is equipped with a circular knife motor, an

angular displacement servo motor and a

cam motor, and the motor Both are connected to the

control circuit; the structure of the cutting machine is relatively complicated, and the stability of the cutting machine in the cutting process is poor, resulting in relatively

poor quality of the cut products

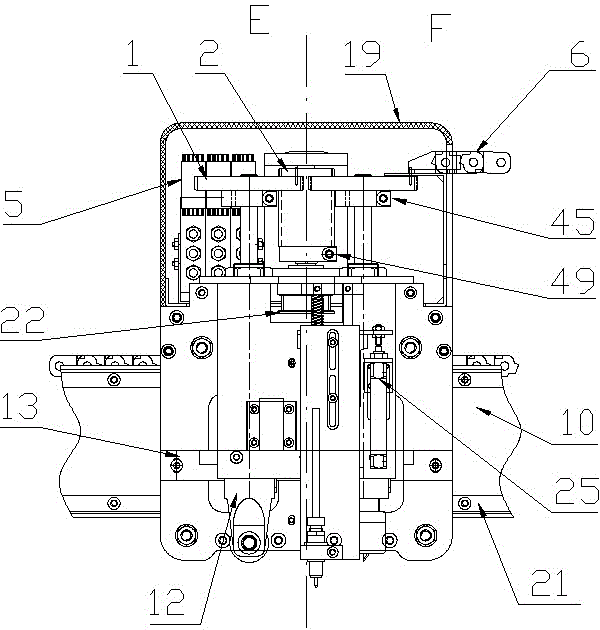

Another example is that the publication date is June 30, 2005, and the publication number is JP2005171420A Japanese Patent, which discloses a high-speed low-level cutting bed, which includes cutting heads, support tables, beams and other parts. A punching drill and a coloring pen are set on the top, the pen is arranged on the pen stand, the pen stand is connected to the vertical end of the first cylinder, and the fixed end of the cylinder is connected to the cutting head; the structural design of the cutting head on the cutting bed is not enough Reasonable, inconvenient to use, difficult to effectively improve the accuracy of cutting

In addition, if the publication date is July 11, 2007, the publication number is CN1994695A in the

Chinese patent, which discloses a multifunctional

cutting tool holder for

pneumatic tool changer, and the

cutting tool holder on the multifunctional

cutting tool holder for

pneumatic tool changer is provided with Mechanisms such as bearing housings, sliding blocks, and rolling spline pairs make the structure of the

pneumatic tool changer multifunctional cutting

tool holder more complicated, the manufacturing cost is higher, the efficiency of equipment operation is lower, and

energy consumption is increased.

[0005] To sum up, there is no cutting head for high-speed low-layer cutting bed with simple structure, reasonable design, scientific

layout, easy operation, convenient use, low production cost, long service life and high cutting accuracy. This reduces the overall performance of the high-speed low-rise cutting bed

Login to View More

Login to View More  Login to View More

Login to View More