Oil phase dispersion sunblocking concentrate of nanometer titania and preparation method thereof

A technology of nano-titanium dioxide and dispersion, which is applied in the direction of cosmetic preparations, skin care preparations, cosmetics, etc., to achieve the effects of low viscosity, uniform dispersion, and favorable production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 15g polyhydroxystearate, 135g C12~C15 alkyl benzoate (AB, British Croda) and 150g modified nano-titanium dioxide (SHU-103 nano-titanium dioxide produced by Shanghai Shanghui Nano Technology Co., Ltd., Particle size 30 ~ 50nm), and put the polyhydroxystearate at 80 ℃ to make it melt completely; then add the weighed polyhydroxystearate and modified nano-titanium dioxide to the C12~C15 alkyl benzoate, and stir and mix evenly with a high-speed mixer; finally, grind the oily dispersion containing nanoparticles with a ball mill for 1 hour, and filter and separate with a 300-mesh filter to obtain a blue coating gloss white oily dispersion concentrate. The concentrate is uniform and stable, with a solid content of 50% and a dynamic viscosity of 230±10mPa·s (25°C).

Embodiment 2

[0029] Weigh 20g of polyhydroxystearic acid, 115g of C12~C15 alkyl benzoate and 165g of modified nano titanium dioxide (SHU-103 nano titanium dioxide produced by Shanghai Shanghui Nano Technology Co., Ltd., particle size 30~ 50nm), and put the polyhydroxystearic acid at 80°C to make it melt completely; then add the weighed polyhydroxystearic acid and nano-titanium dioxide to the C12~C15 alkyl benzoic acid ester in turn during stirring and use a high-speed mixer to stir and mix evenly; finally, grind the oily dispersion containing nanoparticles for 1 hour with a grinder, and filter and separate with a 300-mesh filter to obtain a white oily dispersion concentrate with blue coating luster. The concentrate is uniform and stable, with a solid content of 55% and a dynamic viscosity of 320±10mPa·s (25°C).

Embodiment 3

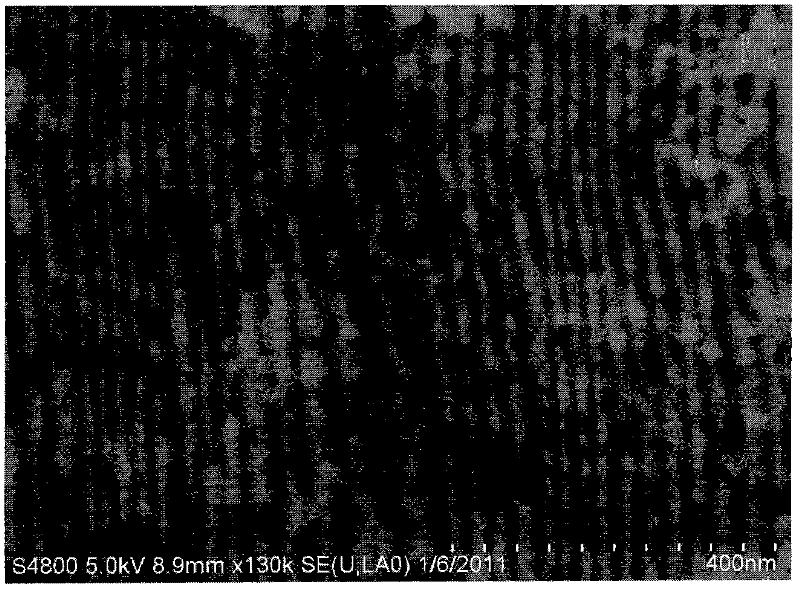

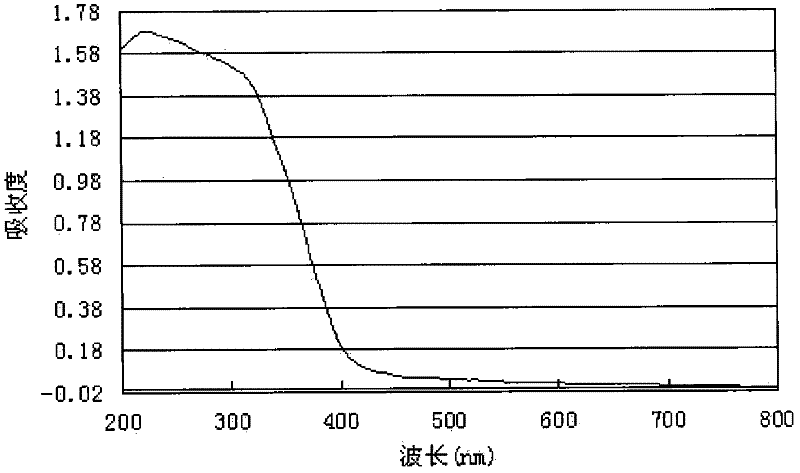

[0031] Weigh respectively 15g of polyhydroxystearate, 150g of C12~C15 alkyl benzoate and 135g of modified nano-titanium dioxide (SHU-103 nano-titanium dioxide produced by Shanghai Shanghui Nano Technology Co., Ltd., particle size 30~50nm), and put the polyhydroxystearic acid at 80°C to melt it completely; then add the weighed polyhydroxystearic acid and nano-titanium dioxide to the C12~C15 alkylbenzyl and use a high-speed mixer to stir and mix evenly; finally, grind the oily dispersion containing nanoparticles for 1 hour with a grinder, and filter and separate with a 300-mesh filter to obtain a concentrated white oily dispersion with blue coating luster things. The concentrate is uniform and stable, with a solid content of 45% and a dynamic viscosity of 80±10mPa·s (25°C). The particle size of the nano-titanium dioxide in the dispersion concentrate is as follows figure 1 shown. Depend on figure 1 It can be seen that there are almost no aggregates in the dispersion concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com