Honokiol or magnolol or honokiol-magnolol mixed solid lipid nanosphere preparation and preparation method thereof

A technology of solid lipid nano and honokiol, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

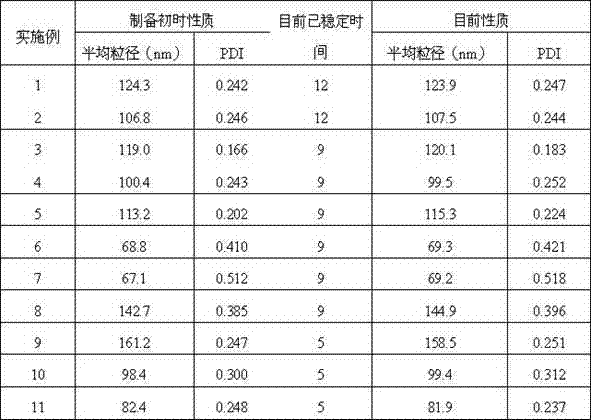

Examples

preparation example Construction

[0016] 1) Preparation of the dispersed phase: heat and melt the solid lipid material, then add honokiol, or magnolol, or a mixture of the two, and mix quickly to form a dispersed phase, or add surfactant to the solid lipid material The agent is heated and melted, then add honokiol or magnolol or the mixture of the two, and quickly mix to form a dispersed phase, or after mixing the honokiol or magnolol or the mixture of the two with the surfactant, quickly Mix evenly with the molten lipid material to form a dispersed phase, place the dispersed phase in an environment of -30 ~ 30 ° C, avoid light, cool and solidify for later use, or keep the molten state and directly perform the following operations;

[0017] 2) Preparation of the continuous phase: when no surfactant is added to the dispersed phase, the surfactant is added to the dispersion medium and mixed to form a continuous phase;

[0018] 3) Particle dispersion: Mix the continuous phase (room temperature or raised to the p...

Embodiment 1

[0024] In practice, the present invention is made of: honokiol 35mg, glyceryl monostearate 0.15g, glyceryl behenate 0.25g, soybean lecithin 50mg, poloxamer 188 0.15g, ultrapure water 10ml, Among them, each part is precisely weighed, and honokiol, glyceryl monostearate, glyceryl behenate, soybean lecithin and poloxamer 188 are mixed, heated, melted and mixed, placed in the refrigerator for solidification, and then the above Put the matrix mixture into the insulation sleeve at 76°C, and add 10ml of ultrapure water at the same temperature at the same time, use an ultrasonic cell pulverizer, under the condition of ultrasonic power 400W, use the probe to ultrasonic 16 times, each ultrasonic 6S, interval 6S, and then keep warm (76°C) absorb the dispersion liquid after ultrasound, pass it through a 0.22 μm microporous membrane while it is hot, cool the filtrate at room temperature and fill it with nitrogen to melt seal, and then obtain honokiol solid lipid nanoparticles.

Embodiment 2

[0026] The present invention can also be made by: honokiol 35mg, glyceryl monostearate 0.15g, glyceryl behenate 0.25g, poloxamer 188 0.15g, ultrapure water 10ml to make, wherein, accurate weighing Take each part, mix honokiol, glyceryl monostearate and glyceryl behenate, heat, melt and mix well, add poloxamer 188 dissolved in 80°C ultrapure water, keep warm (80°C) Under normal circumstances, use a high-speed disperser to disperse for 5 minutes at a speed of 11000r / min, then add the initial dispersion to a heat preservation sleeve at 75°C, use an ultrasonic cell pulverizer, and use a probe to sonicate 20 times at an ultrasonic power of 400W, each time Ultrasound for 10S, interval of 10S, and then keep warm (75°C) to absorb the dispersion after ultrasonication, pass it through a 0.22μm microporous membrane while it is hot, cool the filtrate at room temperature and fill it with nitrogen to melt seal to obtain honokiol solid lipid nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com