Fracturing fluid prepared from simulated stratum produced water or stratum produced water

A technology for simulating formation and produced water, applied in the field of fracturing fluid, it can solve the problems of perishability and alkali-sensitive damage to the bottom layer, and achieve the effects of protecting the environment, saving water resources and energy, and preventing changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

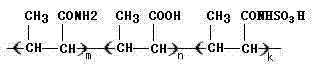

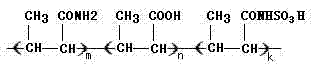

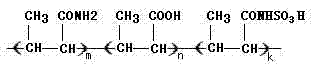

Method used

Image

Examples

Embodiment 1

[0034] 10m on site 3 Add 9560Kg of water to the container, and slowly add 25Kg of thickener while circulating with a pump or agitator, then add 400Kg of potassium chloride, 10Kg of crude oil demulsifier, and 5Kg of sodium lauryl sulfate, and continue to circulate or Stir for 30 minutes so that the liquid is fully mixed and the thickener is fully swollen to form a base liquid.

[0035] 5m on site 3 Add 4975Kg of water to the container, add 5Kg of zirconium oxychloride and 20Kg of ammonium persulfate while stirring with a pump or stirrer, continue to circulate or stir for 30 minutes, so that the zirconium oxychloride and ammonium persulfate are dissolved and mixed fully , to form a cross-linking solution containing a breaker with a content of 0.1% zirconium oxychloride.

[0036] During fracturing construction, while pumping the base fluid, mix the crosslinking fluid with the base fluid at a volume ratio of base fluid: crosslinking fluid = 100 liters: 1 liter to form a fracturi...

Embodiment 2

[0039] 10m on site 3 Add 9540Kg of water to the container, and slowly add 35Kg of thickener while circulating with a pump or stirrer, then add 400Kg of potassium chloride, 10Kg of crude oil demulsifier, and 15Kg of sodium lauryl sulfate, and continue to circulate or Stir for 30 minutes so that the liquid is fully mixed and the thickener is fully swollen to form a base liquid.

[0040] 2m on site 3 Add 980Kg of water to the container, and add 1000Kg of triethanolamine zirconate and 20Kg of ammonium persulfate while circulating with a pump or stirring with a stirrer, and continue to circulate or stir for 30 minutes, so that the triethanolamine zirconate and ammonium persulfate dissolve and Mix well to form a cross-linking solution.

[0041] During fracturing construction, while pumping the base fluid, mix the crosslinking fluid with the base fluid at a volume ratio of base fluid: crosslinking fluid = 100 liters: 0.2 liters to form a fracturing fluid.

[0042] The above fractu...

Embodiment 3

[0044] 10m on site 3 Add 9950Kg of formation produced water into the container, and slowly add 30Kg of thickener, then add 10Kg of crude oil demulsifier, 10Kg of sodium lauryl sulfate, and continue to circulate or stir for 30 minutes , so that the liquid is fully mixed and the thickener is fully swollen to form a base liquid.

[0045] 5m on site 3 Add 4975Kg of water to the container, add 5Kg of zirconium oxychloride and 20Kg of ammonium persulfate while stirring with a pump or stirrer, continue to circulate or stir for 30 minutes, so that the zirconium oxychloride and ammonium persulfate are dissolved and mixed fully , to form a cross-linking solution containing a breaker with a content of 0.1% zirconium oxychloride.

[0046] During fracturing construction, while pumping the base fluid, mix the crosslinking fluid with the base fluid at a volume ratio of base fluid: crosslinking fluid = 100 liters: 1 liter to form a fracturing fluid.

[0047] The above fracturing fluids are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com