Double anti-wear automobile lubricating oil

A vehicle lubricating oil, dual technology, applied in the field of vehicle lubricating oil, can solve the problems of insufficient simulation, insufficient oil film thickness, increased friction pair wear, etc., to reduce wear, improve start-up wear, and extend the oil change period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

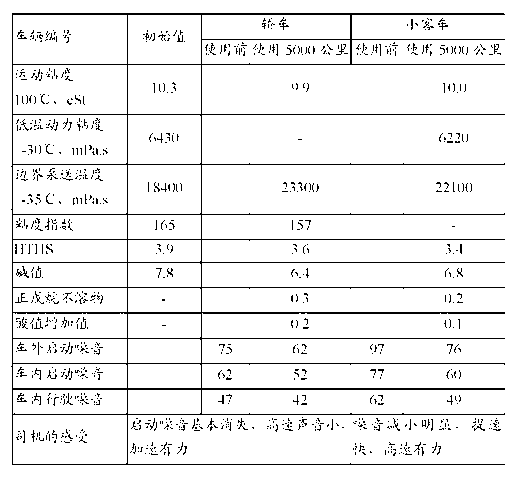

[0022] Add 35-94 mass parts of A in three times, first add 30% of A to the pre-adjusted kettle J, heat to 50 °C at a heating rate of 80-120 °C / hour, add 6.8 mass parts of B, 0.05 mass parts of C and 2 parts by mass of E, at a constant temperature of 50°C for 30 minutes to form a semi-finished material M; add 40% of A to the production blending kettle L, heat it to 80°C at a heating rate of 80-120°C / hour, and add it while stirring 0.3 parts by mass of G, 1 part by mass of D, 2 parts by mass of F and 5.5 parts by mass of H, stirred for 30 minutes, added the remaining 30% of A, stirred for 30 minutes; put the semi-finished material M into the production blending kettle L, stirred After 40 minutes, take samples for analysis, add 0.005-1 parts by mass of pour point depressant, 10-100 ppm of antifoaming agent and 1-100 ppm of demulsifier according to requirements, and stir for another 30 minutes. Table 1 shows the usage result data of the lubricant composition prepared in Example 1....

Embodiment 2

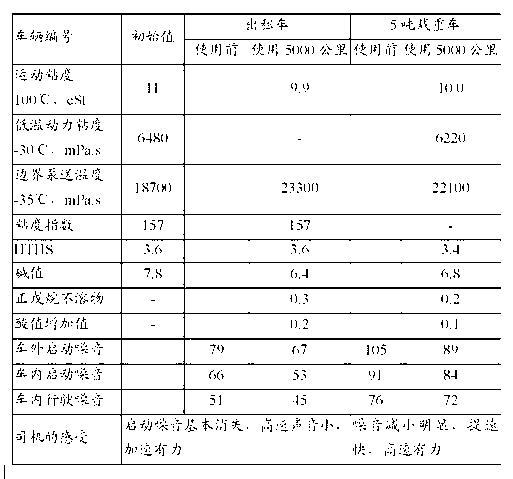

[0026] Add 35-94 parts by mass of A in three times, first add 30% of A to the pre-adjusted kettle J, heat to 50°C at a heating rate of 80-120°C / hour, add 6.8 parts by mass of B, 0.1 parts by mass of C and 5 parts by mass of E, mixed at a constant temperature of 50°C for 30 minutes to form a semi-finished material M; add 40% of A to the production blending kettle L, heat to 80°C at a heating rate of 80-120°C / hour, and add 0.5 mass Parts of G, 1.5 parts by mass of D, 5 parts by mass of F and 7 parts by mass of H, stirred for 30 minutes, added the remaining 30% of A, stirred for 30 minutes; put the semi-finished material M into the production mixing tank L, stirred for 40 minutes Finally, sampling and analysis, according to the requirements, add 0.005-1 mass parts pour point depressant, 10-100ppm antifoaming agent and 1-100ppm demulsifier, and then stir for 30 minutes. Table 2 shows the usage result data of the lubricant composition prepared in Example 2.

[0027] Table 2

[00...

Embodiment 3

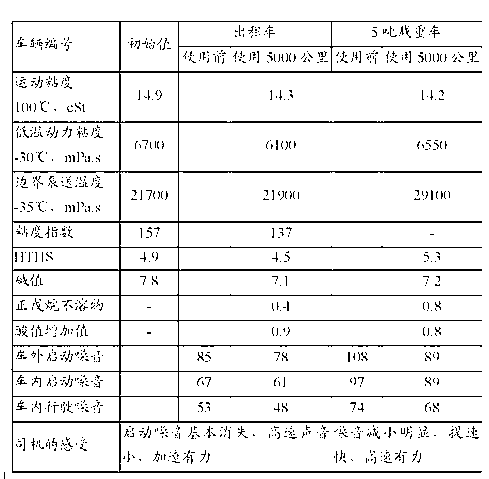

[0030]Add 35-94 parts by mass of A in three times, first add 30% of A to the pre-adjusted kettle J, heat to 50°C at a heating rate of 80-120°C / hour, add 6.8 parts by mass of B, 0.1 parts by mass of C and 8 parts by mass of E are mixed at a constant temperature of 50°C for 30 minutes to form a semi-finished material M; 40% of A is added to the production blending kettle L, heated to 80°C at a heating rate of 80-120°C / hour, and added while stirring 2 parts by mass of D, 5 parts by mass of F and 10 parts by mass of H, stirred for 30 minutes, added the remaining 30% of A, stirred for 30 minutes; put the semi-finished material M into the production blending kettle L, stirred for 40 minutes, and took a sample for analysis , add 0.005-1 parts by mass of pour point depressant, 10-100ppm of antifoaming agent and 1-100ppm of demulsifier according to requirements, and stir for another 30 minutes. Table 3 shows the usage result data of the lubricant composition prepared in Example 3.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com