Microscopic particle rotator of bidirectional conical optical fibers

A technology of micro-particles and rotators, applied in cladding optical fiber, radiation/particle processing, optical waveguide and light guide, etc., can solve the problems of laser optical tweezers, such as bulky, difficult to move, high cost, etc., to achieve large control range, convenient modification, The effect of high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in more detail below in conjunction with accompanying drawing example:

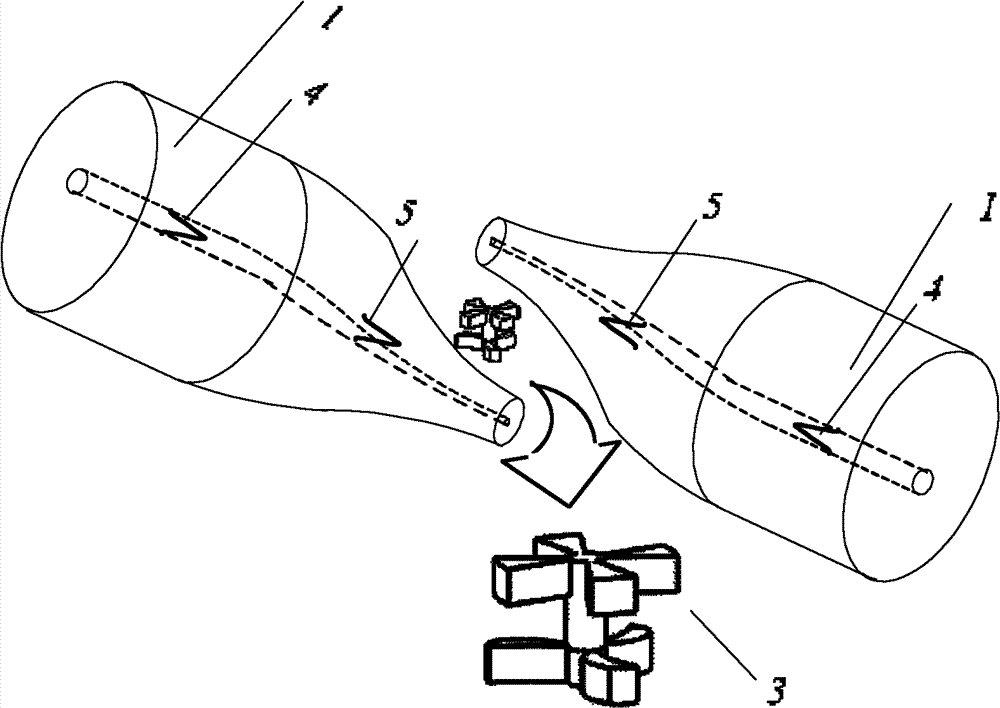

[0033] to combine figure 1 , the first embodiment of the present invention is composed of two standard single-mode optical fibers 1, which are made of a tapered optical fiber 2 and a double-body microparticle 3, which are cut by fusion tapering, and inject light into the two tapered optical fibers . Because of the special structure of the tapered fiber, the transmitted light 4 in the fiber core is transmitted out of the cladding in the form of evanescent waves 5 and acts on the tiny particles 3, and this part of the transmitted evanescent field generates light radiation pressure on the tiny particles 3 Torsion torque is formed to realize rotation.

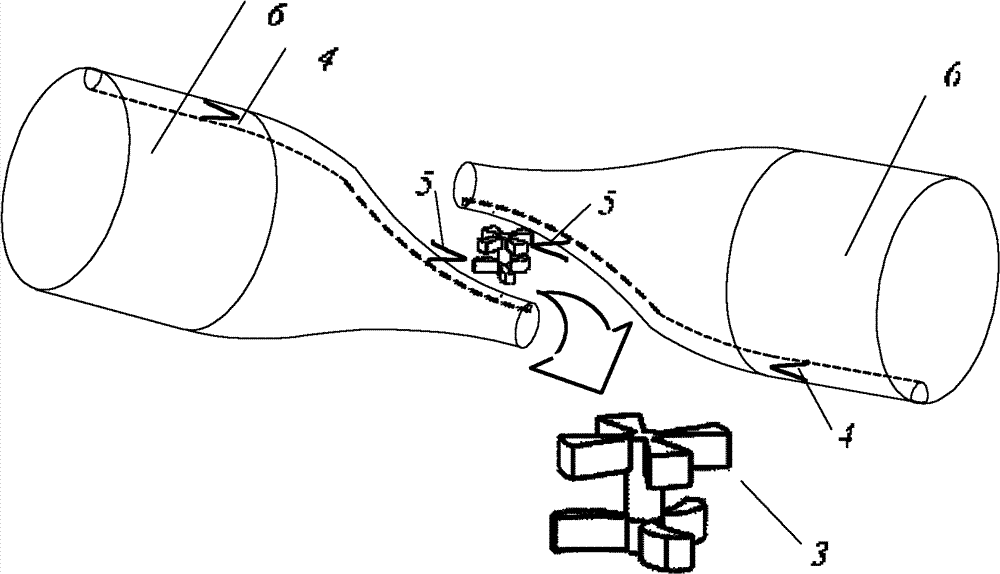

[0034] to combine figure 2 , The second embodiment of the present invention is composed of two surface single-core optical fibers 6 which are made of a tapered optical fiber and double-body micro-particles 3 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com