Solar cell panel dedusting comb-shaped circuit and working system thereof

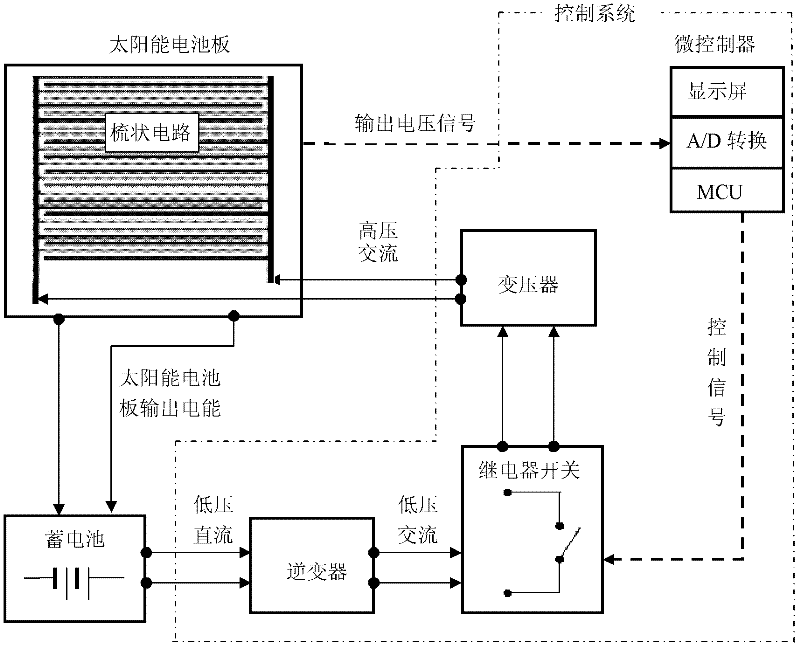

A technology of solar panels and working systems, applied in the field of solar power generation, can solve the problems of dust being difficult to clean, dust has a great adsorption force, and the cost of manpower and material resources, etc., to achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

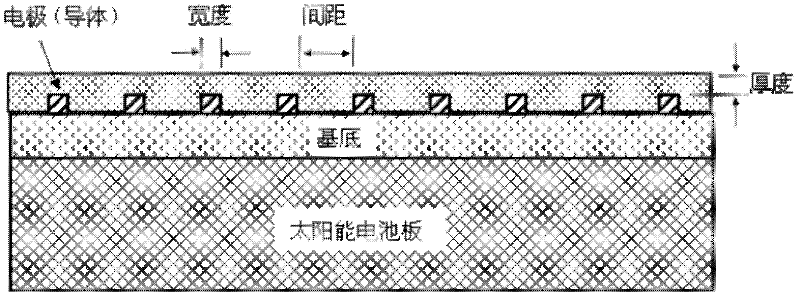

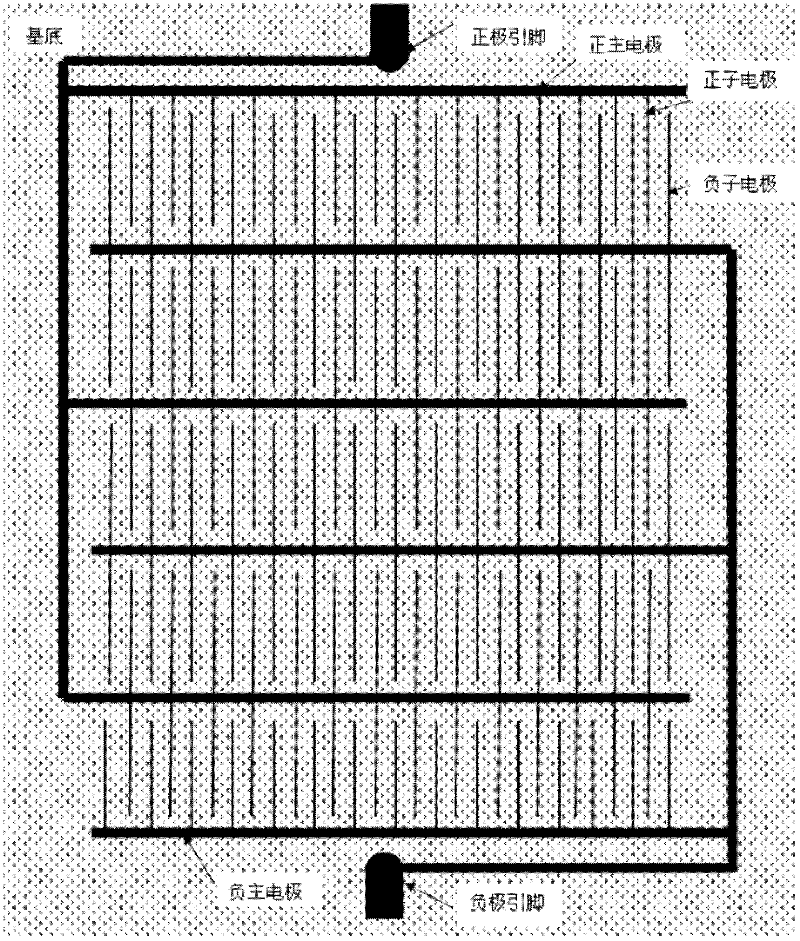

[0017] figure 1 It is a cross-sectional view of the dust removal comb circuit of the solar panel. The comb circuit is attached to the surface of the solar panel; the comb circuit is composed of a base layer, a circuit layer, and a transparent insulating protective film. The base layer is made of glass or transparent resin material. The base layer One side of the solar panel is attached to the surface of the solar panel, and the other side is laid with a circuit layer, which plays the role of isolating the solar conductive layer and the circuit layer of the comb circuit; the circuit layer includes three parts: the electrode pin part, the main electrode part and the sub-electrode part; the circuit layer The surface is covered with a transparent insulating protective film. The minimum thickness of the transparent insulating protective film is 50-150 microns, which prevents bre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com