Antibacterial biaxially oriented polypropylene film and preparation method thereof

A technology of biaxially stretched film and antibacterial polypropylene, which is applied in the field of antibacterial polypropylene biaxially stretched film and its preparation, and can solve problems such as cumbersome production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

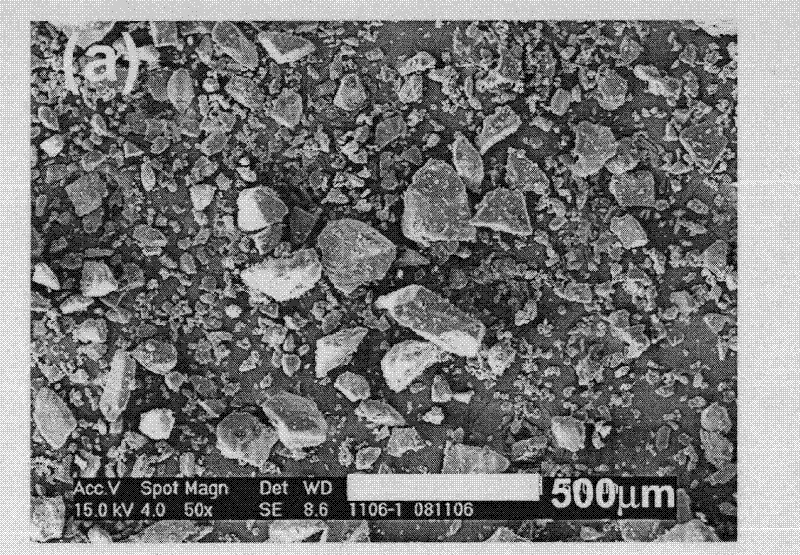

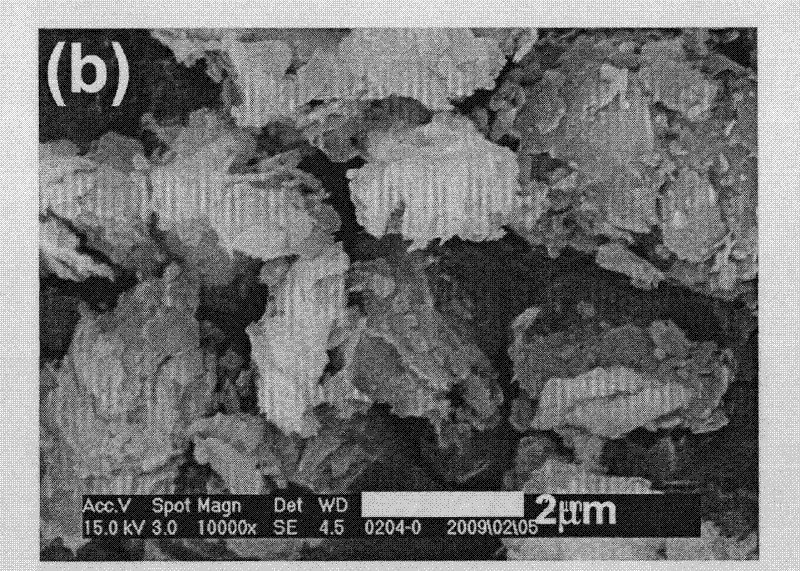

[0070] Weigh 60.0 g of inorganic montmorillonite (Zhejiang Fenghong Clay Chemical Co., Ltd. MMT, sheet thickness 20-30 nm, sheet width 1 μm-30 μm), and add it to 20.0 g of polyhexamethyleneguanidine propionate (Shanghai High Polyguanidine F3000) in an aqueous solution (concentration is 10% wt), heated to 80 ° C, vigorously stirred for 8 hours, then the suspension was put into an oven for drying, and the dried product was put into a pulverizer to pulverize to obtain polyguanidine / Montmorillonite composite antibacterial agent (composite antibacterial agent 1), wherein the ratio of polyhexamethylene guanidine propionate to montmorillonite is 1:3.

Embodiment 2

[0072] Montmorillonite 80.0g (same as Example 1) is added to the ethanol solution (concentration is 10%wt) of 20.0g polyhexamethyleneguanidine hydrochloride (Shanghai High Poly Corporation F1000), and other steps are the same as Example 1 . A polyguanidine / montmorillonite composite antibacterial agent (composite antibacterial agent 2) was obtained, wherein the ratio of polyhexamethyleneguanidine hydrochloride to montmorillonite was 1:4.

Embodiment 3

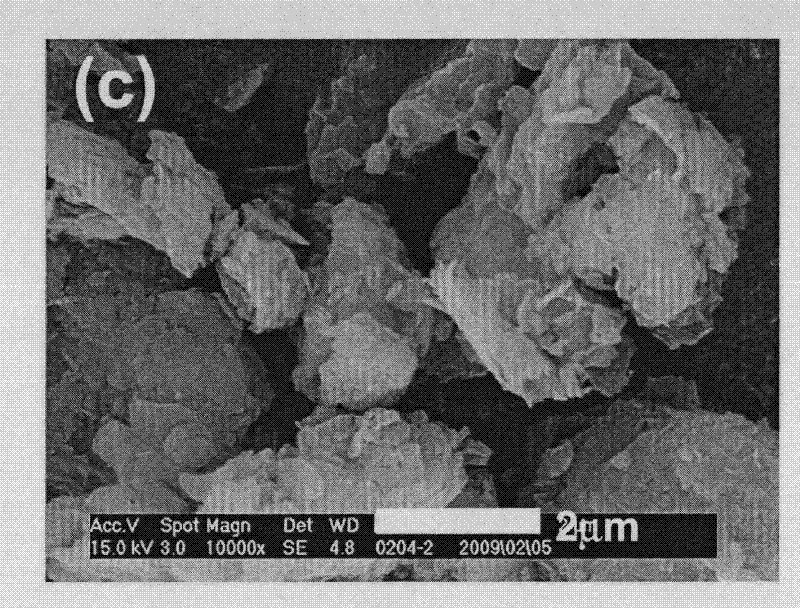

[0074] Take by weighing montmorillonite 1000.0g (same as embodiment 1), join in the aqueous solution (concentration is 30%wt) that contains 300.0g polyhexamethylene biguanide hydrochloride (Shanghai Shan's Industrial Co., Ltd. PMHB), utilize spray Drying equipment for drying. The inlet temperature is set at 170°C, the outlet temperature is set at 80°C, and the ejected product is polyguanidine / montmorillonite composite antibacterial agent (composite antibacterial agent 3), in which polyhexamethylene biguanide hydrochloride and montmorillonite The ratio is 1:3.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com