Preparation method of single crystal silicon texture surface structure

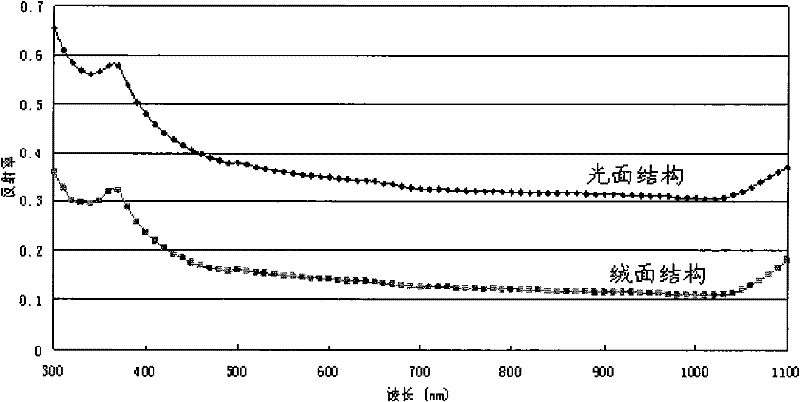

A monocrystalline silicon and suede technology, which is applied in the field of solar energy applications, can solve the problems of restricting production capacity, slow formation speed of suede surface, and limitation of battery efficiency, etc., and achieve the effects of increasing production capacity, saving process time, and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

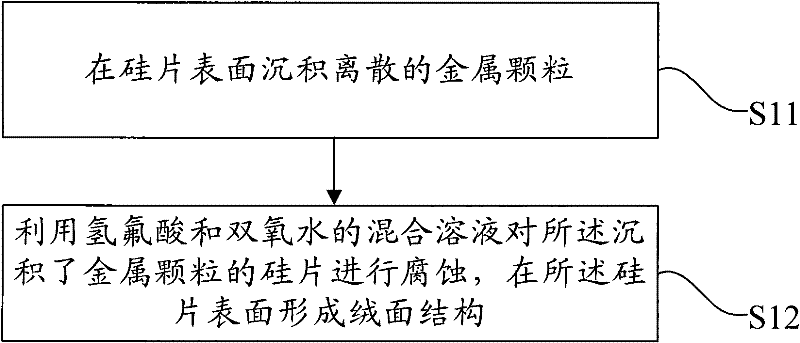

[0022] The preparation method of the suede that the embodiment of the present invention provides, such as image 3 The flowchart shown includes:

[0023] S11, depositing discrete metal particles on the surface of the silicon wafer;

[0024] S12, using a mixed solution of hydrofluoric acid and hydrogen peroxide to etch the silicon wafer on which the metal particles are deposited, to form a textured structure on the surface of the silicon wafer.

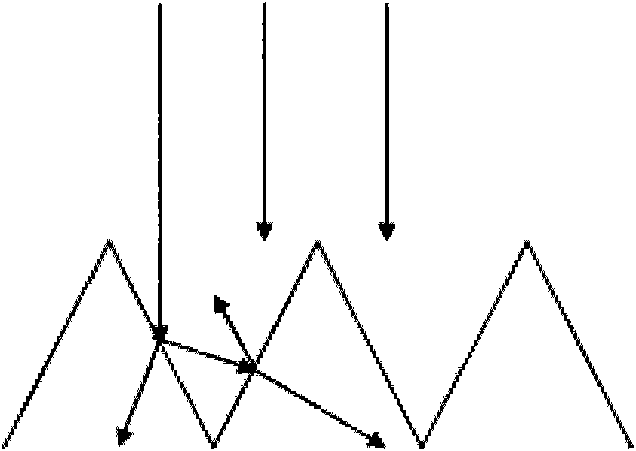

[0025] The suede preparation method provided in the embodiment of the present invention may be called a metal-catalyzed silicon corrosion method. At present, in the field of scientific research, the metal-catalyzed silicon etching method is mainly used to prepare silicon nanostructures, such as quantum dots, porous silicon, nanowires, etc. Its main principle is that in the environment of strong oxidizing HF acid solution, metal particles are used as catalysts to oxidize the silicon surface in contact with the metal particles through ...

Embodiment 1

[0044] The preparation method of the suede that present embodiment provides, as Figure 5 The flow chart shown includes the following steps:

[0045] S21, performing standard cleaning on the silicon wafer;

[0046] S21, using the chemical plating method, immerse the silicon wafer in HF and silver nitrate (AgNO 3 ) in the mixed solution, depositing discrete Ag particles on the surface of the silicon wafer.

[0047] This step is carried out at room temperature, the reaction time is 1min, the HF and AgNO 3 In the mixed solution, the concentration of HF is 10%, AgNO 3 The concentration is 0.01~0.03Mol / L. After this step, discrete and evenly distributed Ag particles will be deposited on the surface of the silicon wafer. After this step, the topography of the silicon wafer surface is as follows: Image 6 As shown, the white particles in the figure are deposited Ag particles. It can be seen from the figure that the deposited Ag particles are discrete, evenly distributed and com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com