Multi-fuel energy-saving furnace

An energy-saving furnace and fuel technology, which is used in solid heating fuels, household furnaces/stoves, lighting and heating equipment, etc., can solve the problems of insufficient combustion of fuel and air, low utilization of heat energy, and insufficient combustion. , to achieve the effect of using smokeless, high combustion value and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

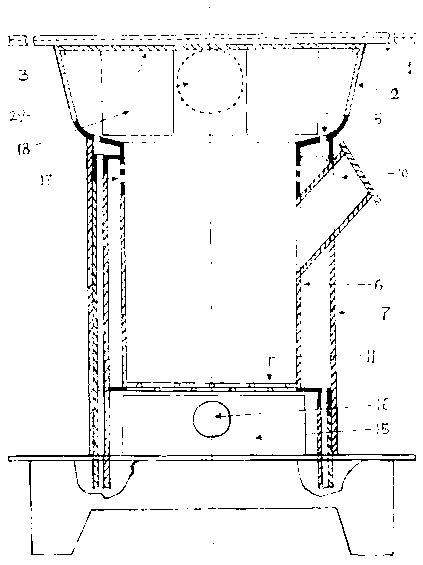

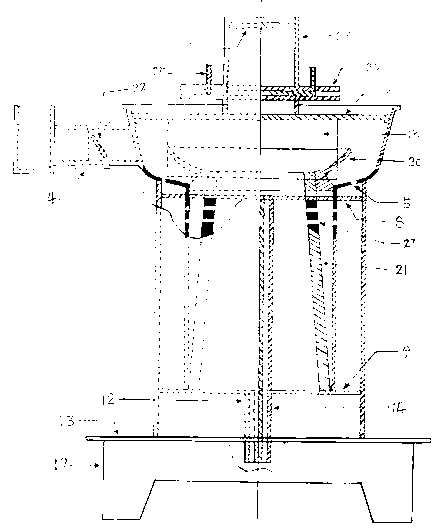

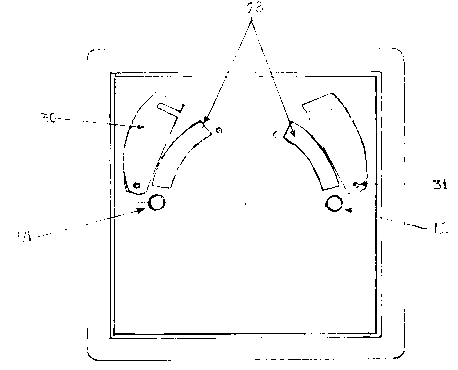

[0021] Example 1. Used to burn coal.

[0022] Such as figure 1 or figure 2 As shown, it includes a furnace panel 1, a furnace pot 2, a furnace cylinder 6, a furnace outer cylinder 7, a third air inlet partition 8, a secondary air inlet pipe 12, a furnace foot bottom plate 13, a third air inlet pipe 14, an ash box 15, Fire baffle ring 18, furnace foot side plate 19, air return ring 20 and furnace core 21, furnace panel 1 is a movable type, is placed on the furnace basin 2 when in use, and is pinned by two latches. There is a furnace ring 3 and a flue gas outlet hole 29 on the furnace basin 2, and a flue gas elbow joint 4 is connected to the flue gas outlet hole 29, and a thermal energy adjustment and heat preservation is installed on the flue gas elbow joint 4. valve 22. There are three air inlet holes 5 in a circle at the bottom of the stove basin 2 . The furnace basin 2 is welded together with the hearth cylinder 6 and the furnace outer cylinder 7 , the furnace ou...

Embodiment 2

[0024] Example 2. It is used to burn firewood, various crop straws and other waste combustibles.

[0025] Such as figure 1 As shown, it includes a furnace panel 1, a furnace basin 2, a furnace cylinder 6, a furnace outer cylinder 7, a third air inlet partition 8, a secondary air inlet pipe 12, a furnace foot bottom plate 13, a third air inlet pipe 14, an ash box 15, Fire baffle ring 18, stove foot side plate 19 and air return ring 20, stove panel 1 are movable, are placed on the stove basin 2 when in use, are pinned by two latches. There is a furnace ring 3 and an exhaust gas outlet hole 29 on the furnace basin 2, and a smoke exhaust gas elbow joint 4 is connected to the smoke exhaust gas outlet hole 29, and a thermal energy adjustment heat preservation device is installed on the exhaust gas elbow joint 4. valve 22. There are three air inlet holes 5 in a circle at the bottom of the stove basin 2 . The furnace basin 2 is welded together with the hearth cylinder 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com