Silicon oxide compound silver powder and preparation method thereof as well as conductive silver paste

A technology of conductive silver paste and silicon oxide, applied in metal/alloy conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. The effect of improving electrical performance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

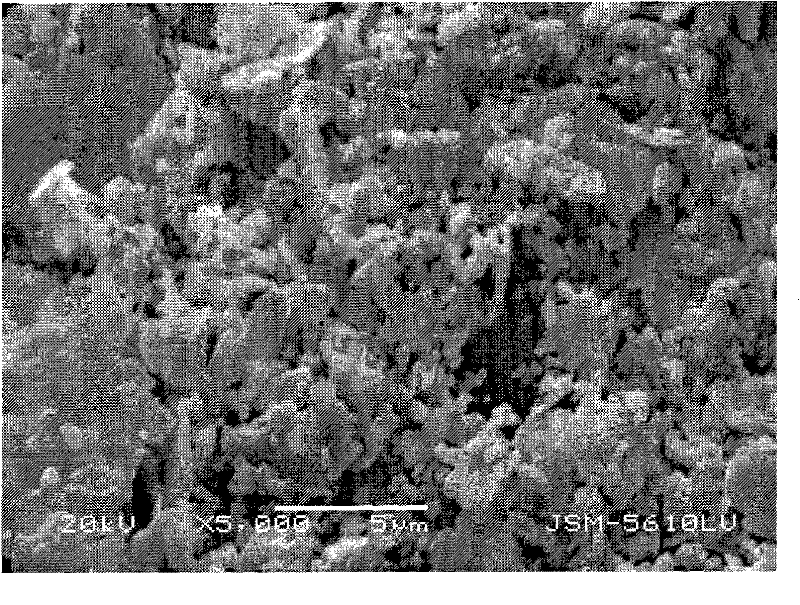

Image

Examples

preparation example Construction

[0017] The invention provides a kind of preparation method of silica composite silver powder, comprises the following steps:

[0018] a. Mix the silver powder and neutral silica sol evenly, wash, dry, and pulverize to obtain the initial product;

[0019] b. Dispersing the initial product in step a in ethanol, adding a dispersing aid, ball milling, washing, drying and pulverizing to obtain the silicon oxide composite silver powder.

[0020] The preparation method of the neutral silica sol adopted in the present invention is well known to those skilled in the art, for example, it can be prepared by the following method: deionized water, ethanol, ethyl tetrasilicate and nitric acid are mixed in a mass ratio of 15- 20: 150-200: 70-80: 0.5-1.0 and mix evenly, then add lye to adjust the pH value to 5-7 to obtain the neutral silica sol. Preferably, the mass ratio of deionized water, ethanol, tetraethyl orthosilicate and nitric acid is 36:320:145:1. The lye is various alkalis common...

Embodiment 1

[0038] This example is used to illustrate the silicon oxide composite silver powder provided by the present invention and its preparation method.

[0039] a. Preparation of neutral silica sol: mix deionized water, ethanol, tetraethyl orthosilicate and nitric acid evenly in a mass ratio of 36:350:150:1.5, mechanically stir for 1 hour, settle for 1 day, and then add alkali The pH value of the solution was adjusted to 5-7, and the neutral silica sol was obtained by filtration.

[0040] b. Disperse 500 g of spherical silver powder with an average particle size of 1.30 μm in the neutral silica sol in step a, mechanically stir for 20 minutes, wash with ethanol for 3 times, dry and pulverize to obtain the initial product.

[0041] c. Disperse the initial product of step b in 800g ethanol, add dispersing aids glycerol 4.5g, PVP 3.5g, zinc stearate 3.0g, then add 3500g zirconia balls (□3) into the planetary ball mill (Nanjing University Instrument Factory), ball milled for 10 hours, w...

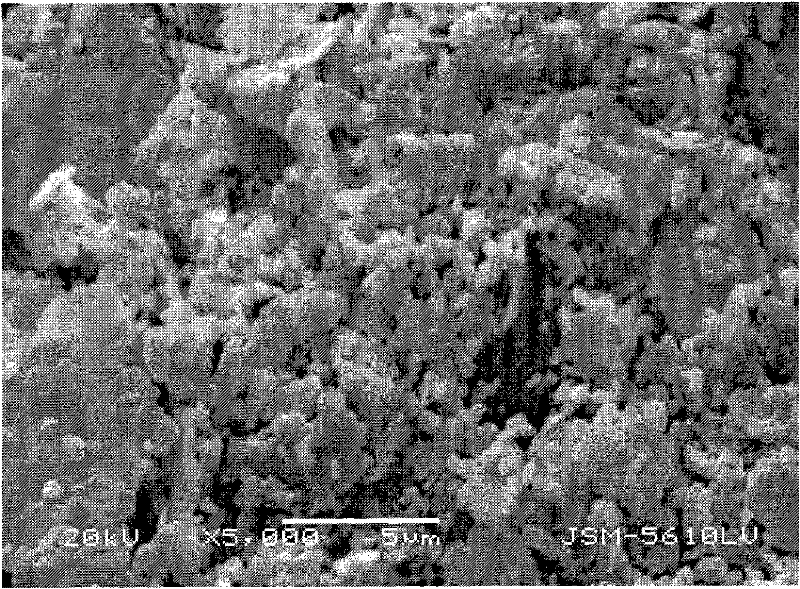

Embodiment 2

[0043] Adopt the method similar to Example 1 to prepare the silicon oxide composite silver powder of the present embodiment, the difference is: in the step b, get 500g of spherical silver powder with an average particle diameter of 1.50 μm and soak it in the neutral silica sol, mechanically stir for 30 Minutes, washed 3 times with ethanol, dried and pulverized.

[0044] Through the above-mentioned steps, the silicon oxide composite silver powder of this embodiment was obtained, denoted as A2, and the mass ratio of silicon oxide and silver particles in the silicon oxide composite silver powder was 2.24:100 according to the EDS test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com