Electromagnetic pump cooling system and control method thereof

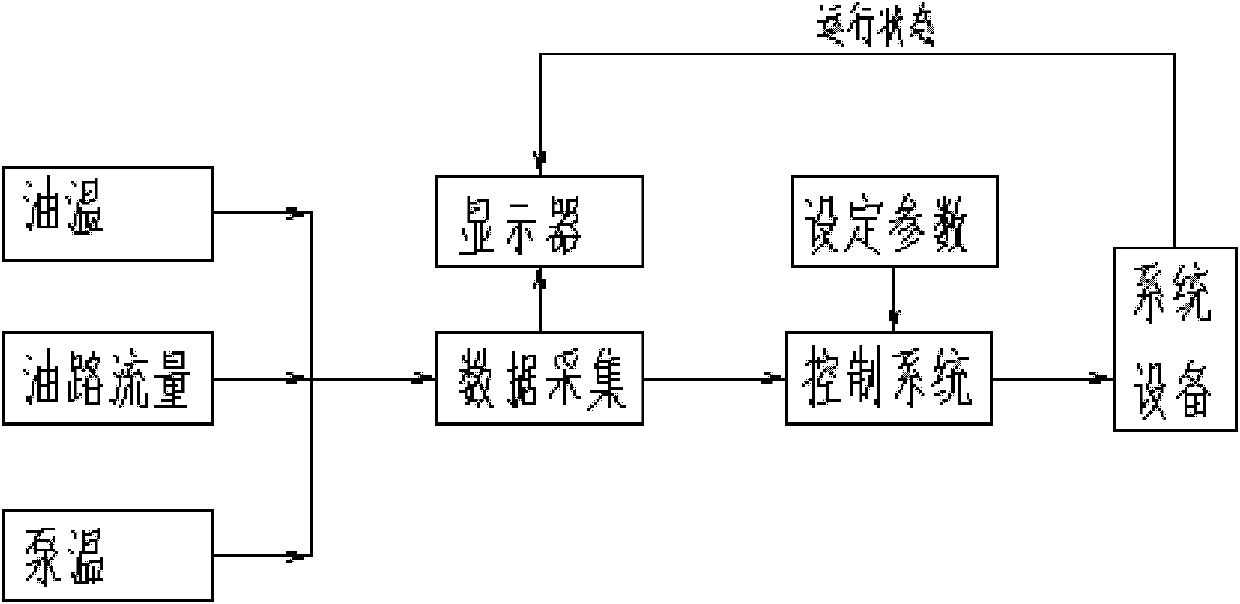

A cooling system, electromagnetic pump technology, applied in the direction of pump control, pump components, variable capacity pump components, etc., can solve the problems of limiting the working capacity and safety of electromagnetic pumps, limited cooling capacity, reducing flow resistance, etc., to avoid Electromagnetic pump operation accidents, strong cooling capacity, and the effect of avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

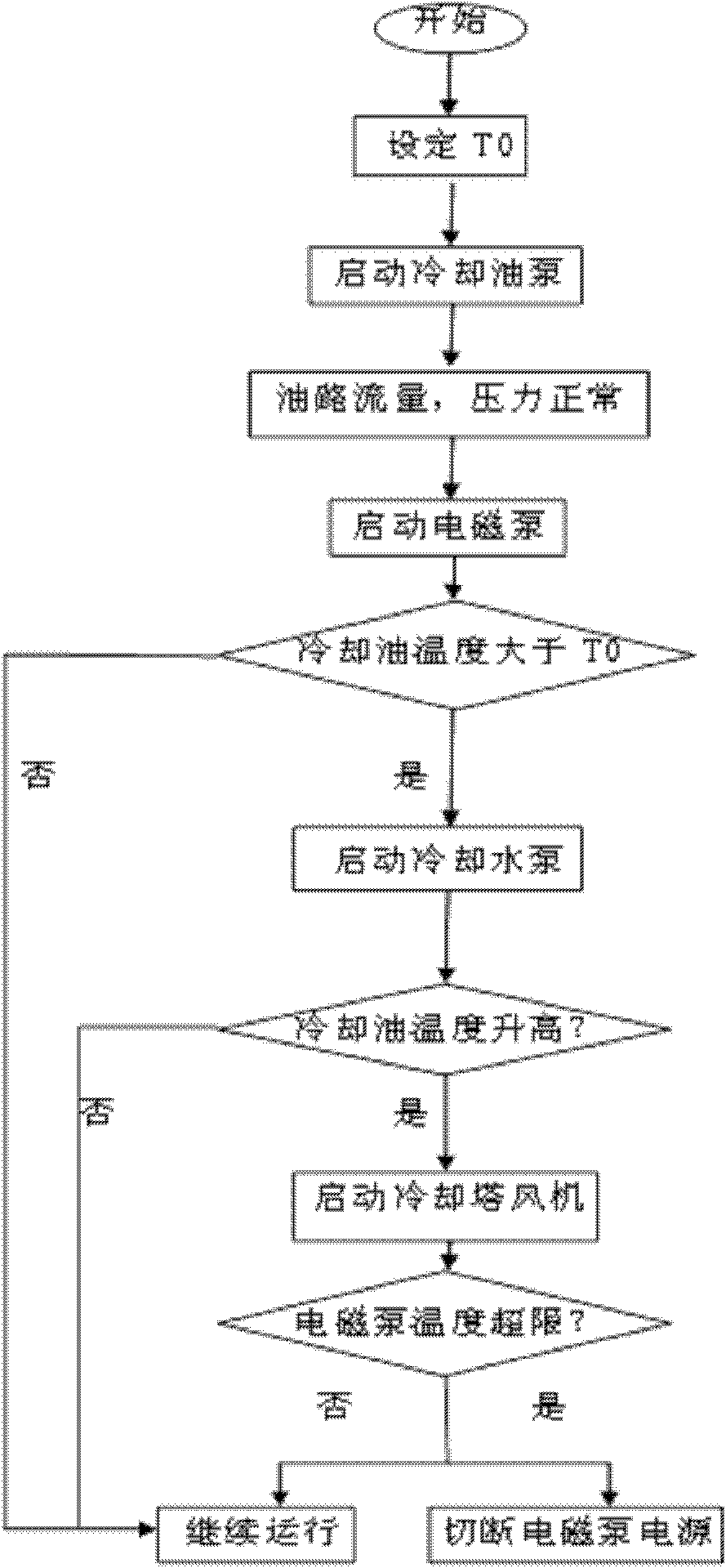

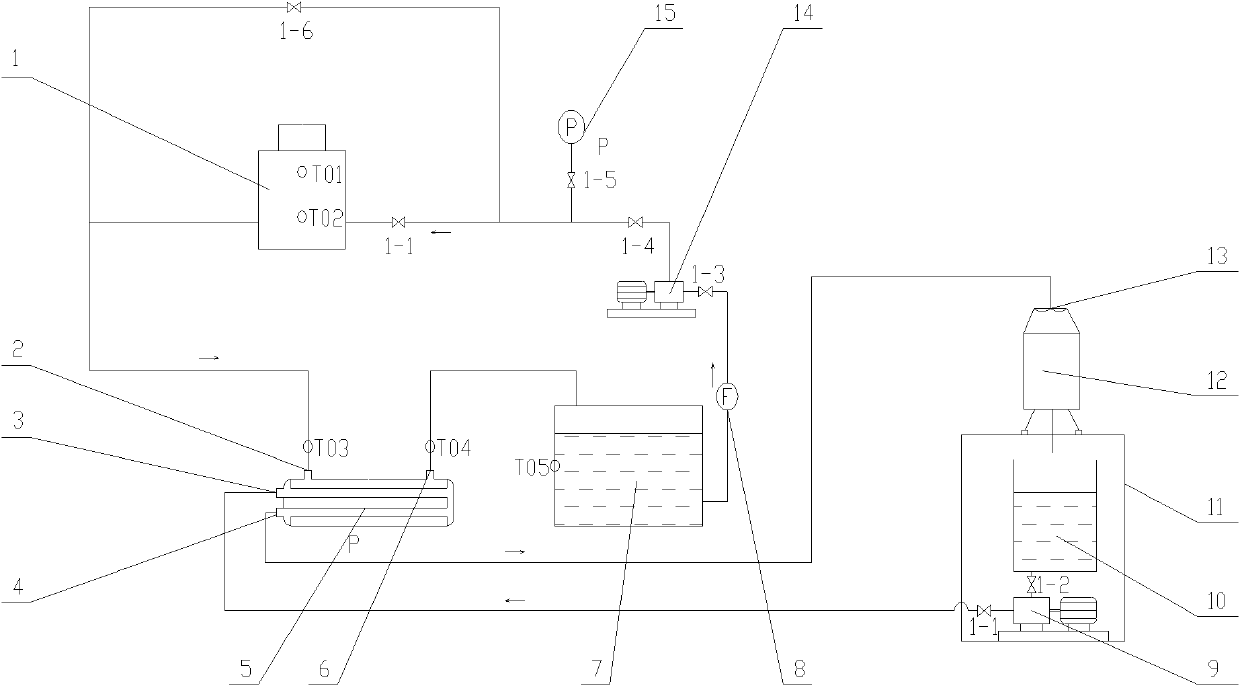

[0032] Example 1: Electromagnetic pump operates under low flow conditions

[0033] Such as image 3 , the current liquid metal circuit needs 1m 3 / h flow rate. First, set T0 to 60°C, start the cooling oil pump 14, and satisfy the interlocking conditions for starting the electromagnetic pump. After checking that the flow rate and oil pressure of the oil circuit are normal, the power of the electromagnetic pump can be turned on, and the electromagnetic pump starts to preheat under low voltage. During the preheating period, the oil circuit bypass valve 1-6 should be properly adjusted to reduce the flow through the electromagnetic pump The cooling oil flow of the pump is convenient for preheating.

[0034] When the temperature T01 and T02 of the electromagnetic pump both reach about 150°C, the liquid metal sodium can be charged into the electromagnetic pump, and the electromagnetic pump starts to run officially, and the oil bypass valve 16 is closed at the same time. At this t...

Embodiment 2

[0036] Example 2: Electromagnetic pump operates under medium flow conditions

[0037] Such as image 3 , the current liquid metal circuit needs 5m 3 / h flow rate. First, set T0 to 60°C, start the cooling oil pump 14, and satisfy the interlocking conditions for starting the electromagnetic pump. After checking that the oil flow and oil pressure are normal, turn on the power supply of the electromagnetic pump and adjust its input voltage to about 100V for preheating. At this time, the oil bypass valve 16 remains closed, and all the cooling oil flows through the electromagnetic pump.

[0038] When the temperature T01 and T02 of the electromagnetic pump both reach about 150°C, fill the electromagnetic pump with liquid metal sodium, and the electromagnetic pump starts to run. At this time, adjust the flow rate of the liquid metal to 5m by adjusting the input voltage of the electromagnetic pump 3 / h.

[0039] During operation, in order to provide 5m 3 / h flow rate, the power o...

Embodiment 3

[0040] Example 3: Electromagnetic pump operates under higher flow conditions

[0041] Such as image 3 , the current liquid metal circuit needs 9m 3 / h flow rate. First, set T0 to 60°C, start the cooling oil pump 14, and satisfy the interlocking conditions for starting the electromagnetic pump. After checking that the oil flow and oil pressure are normal, turn on the power supply of the electromagnetic pump and adjust its input voltage to about 100V for preheating. At this time, the oil bypass valve 16 remains closed, and all the cooling oil flows through the electromagnetic pump.

[0042] When the temperature T01 and T02 of the electromagnetic pump both reach about 150°C, fill the electromagnetic pump with liquid metal sodium, and the electromagnetic pump starts to run. At this time, adjust the flow rate of the liquid metal to 9m by adjusting the input voltage of the electromagnetic pump 3 / h.

[0043] To maintain 9m 3 At a flow rate of / h, the electromagnetic pump is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com