Infrared laser in ultra quantum conversion limit based on optic superlattice and construction method thereof

A technology of optical superlattice and construction method, applied in the fields of nonlinear frequency conversion and laser, can solve the problems of disadvantageous high conversion efficiency, difficult to obtain large aperture, high optical quality optical superlattice, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

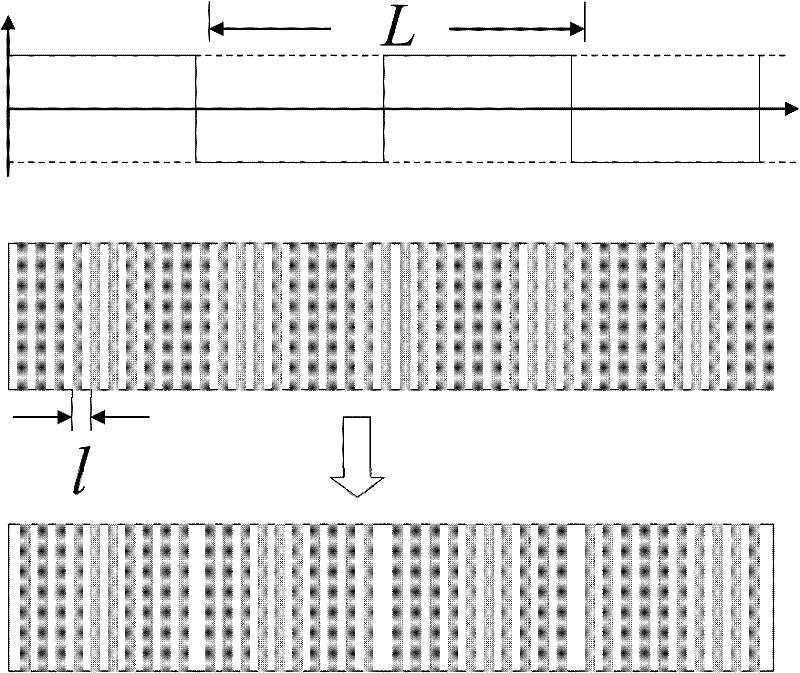

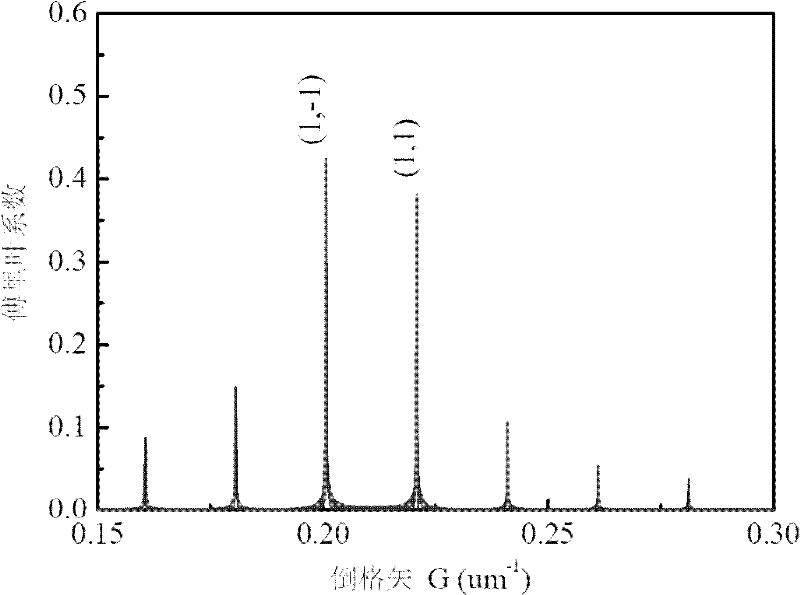

Method used

Image

Examples

Embodiment 1

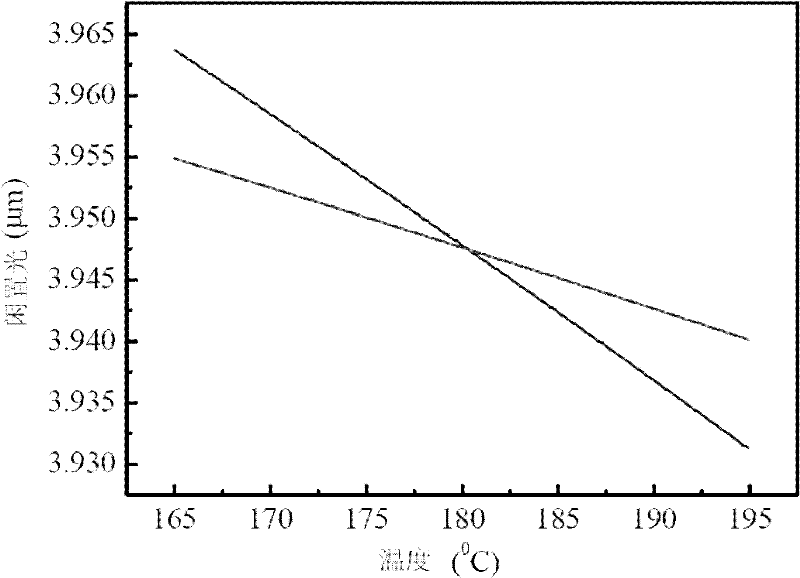

[0050] according to Figure 4 Fabrication of a mid-infrared laser based on the ultra-quantum switching limit of an optical superlattice. The 1064nm laser 1 used to pump the OPO-OPA resonator, the 1064nm 45-degree high-reflection flat mirror 2, 3; the attenuator 4, 5 that can continuously tune the pump light power is a mode selection hole; the pump light passes through the lens 6 focus on the commensurate-ratio double-period superlattice 9, the superlattice is placed in a temperature-controlled furnace 10, and placed together in a resonant cavity composed of two concave mirrors with a curvature of 100mm, and the cavity length is about 100mm; Both ends of the lattice are coated with 1064, 1400-1500, and 3800-4200nm anti-reflection coatings, and the two-cavity mirror is coated with 1400-1500nm high-reflection coatings, 1064 and 3800-4200nm anti-reflection coatings, so the resonant cavity is a single resonance of signal light; 11 The filters are filters that only allow mid-infrar...

Embodiment 2

[0052] according to Figure 4 Fabrication of a mid-infrared laser based on the ultra-quantum switching limit of an optical superlattice. The difference from Example 1 is that the wavelength of the OPO-OPA resonator laser 1 used to pump is 1.3 μm, and the flat mirror 2, 3 with a 45-degree high reflection to 1.3 μm; the attenuator 4, 5 that can continuously tune the pump optical power It is a small hole for mode selection; the pump light is focused on a commensurate double-period superlattice 9 through a lens 6, and the superlattice is placed in a temperature-controlled furnace 10, and is placed together in a resonance composed of two concave mirrors with a curvature of 100mm In the cavity, the cavity length is about 100mm; both ends of the superlattice are coated with 1.3μm, 2μm and 3.9μm antireflection coatings, and the two cavity mirrors are coated with 2μm high reflection coatings, 1.3μm and 3.9μm antireflection coatings, so the resonant cavity is the signal Optical single ...

Embodiment 3

[0054] according to Figure 4 Fabrication of a mid-infrared laser based on the ultra-quantum switching limit of an optical superlattice. The difference from Embodiments 1 and 2 is that the superlattice used for nonlinear frequency conversion is a cascaded periodic structure, and different matching temperatures and periods can be designed according to the needs of the specific matching process to achieve enhanced output of mid-infrared light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com