Molding method of fine grain graphite

A molding method and fine particle technology are applied in the field of graphite to achieve the effects of low cost, simple structure and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

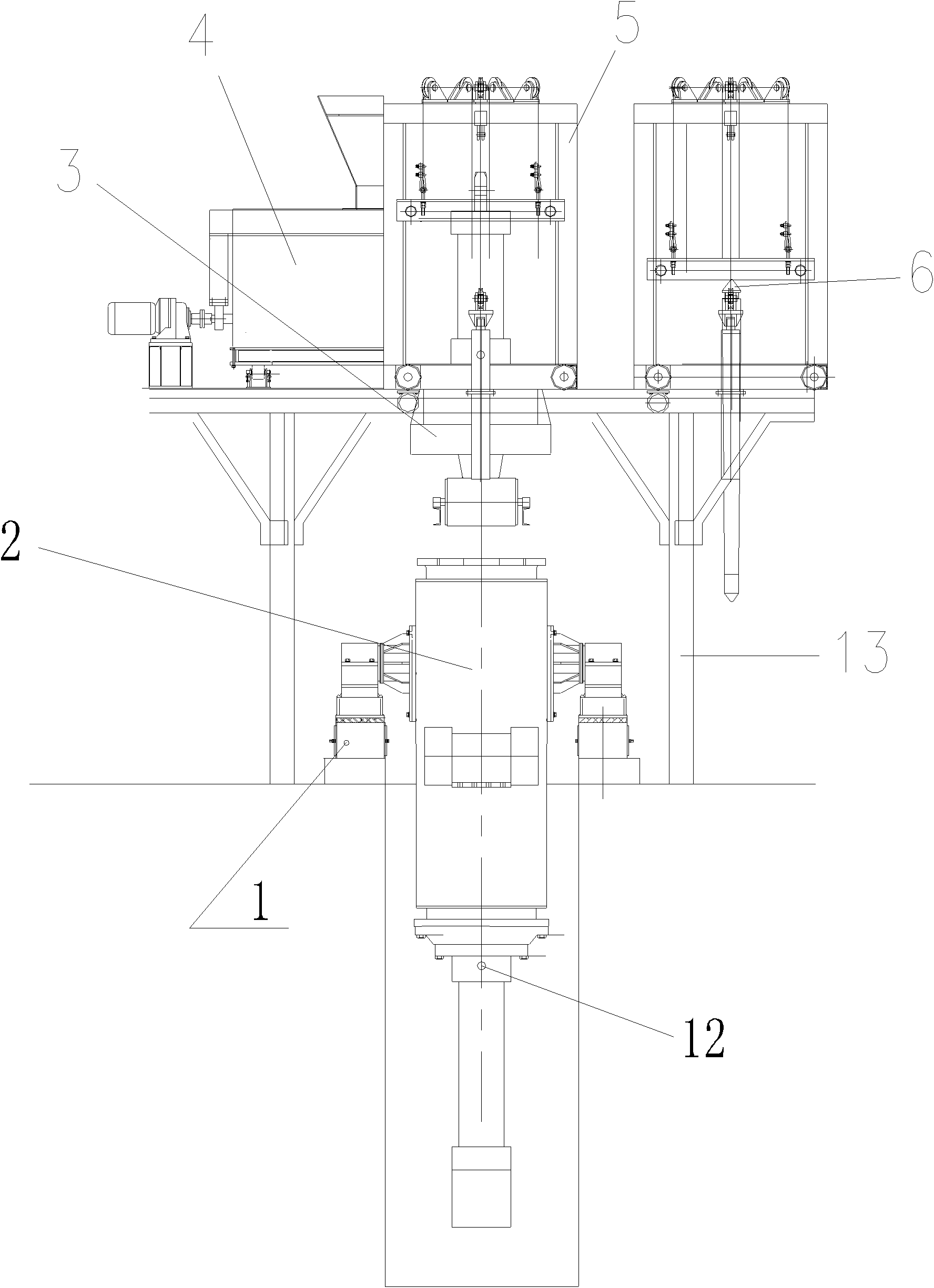

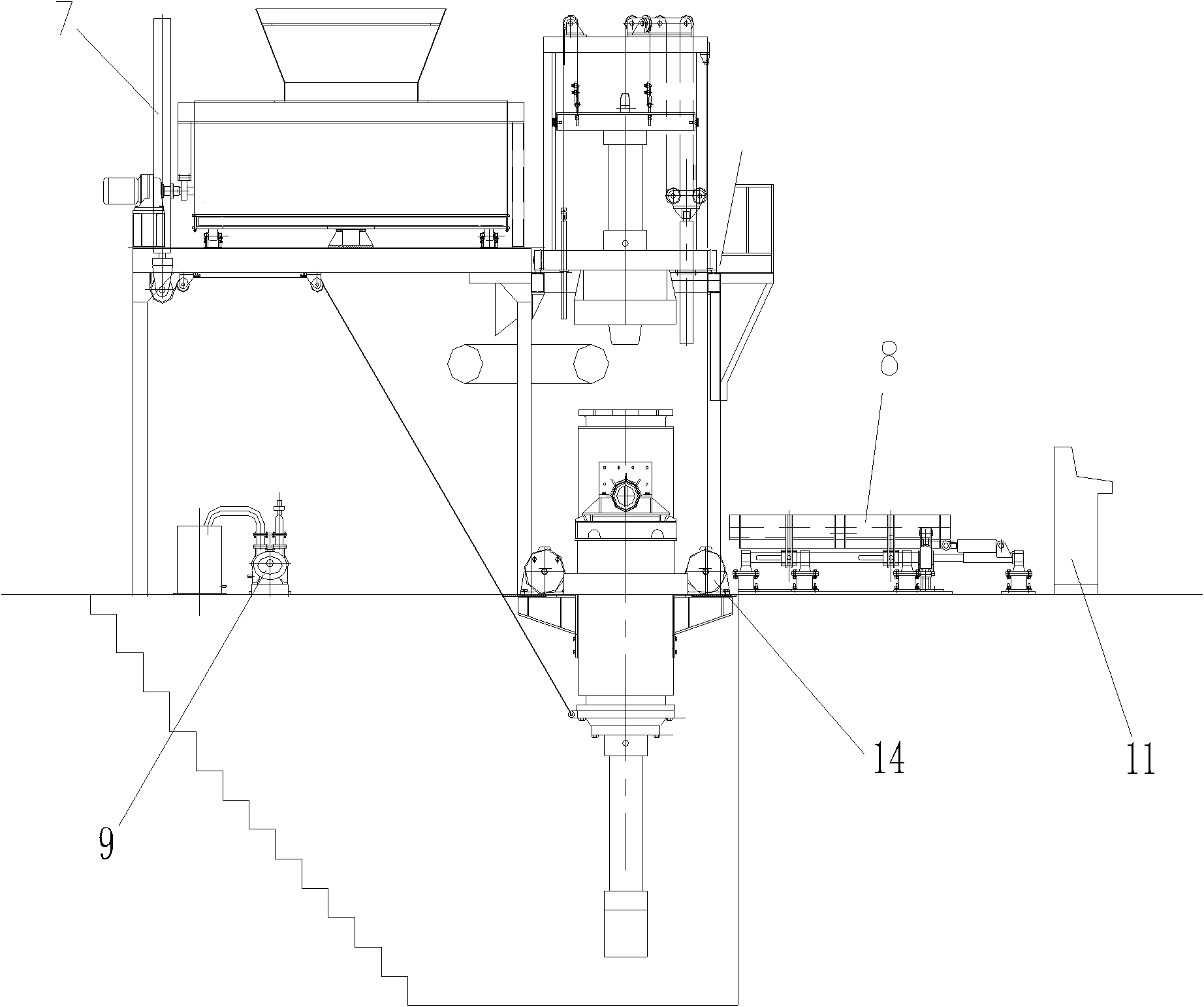

[0036] The present invention adopts such as figure 1 with 2 The difference between the main technical data of the graphite electrode forming machine shown and the ordinary vibration forming machine is:

[0037] Specific pressure: the ordinary vibration molding machine is 0.3-0.4MPa, while the specific pressure of the graphite electrode molding machine is 2-3MPa;

[0038] Pressurization method: Ordinary vibration forming machine is one-way pressurization, but this graphite electrode forming machine is two-way pressurization, and its pressure reaches more than 200 tons;

[0039] Vibration source application method: ordinary vibration molding machine is applied by vibration at the bottom of the mold, and this graphite electrode molding machine is applied in the middle.

[0040] The graphite electrode molding machine is equipped with an electrode trolley 8, a vacuum system 9, a hydraulic system 10, an electric control system 11 and a frame 13, and also has a rubber spring base 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com