Tube array and remaining tank dissolving-out system and method for gibbsite bauxite

A gibbsite-type and bauxite technology, applied in the direction of alumina/hydroxide, etc., can solve problems such as unreasonable economics, high equipment manufacturing costs, and large system resistance loss, so as to reduce the difficulty of production operations and maintenance difficulty, reduced operating costs, and long operating cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

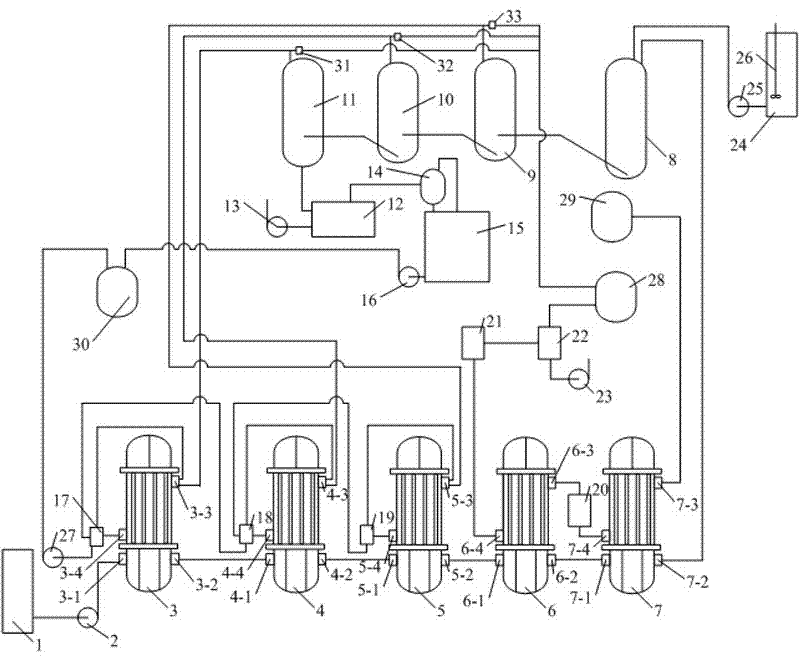

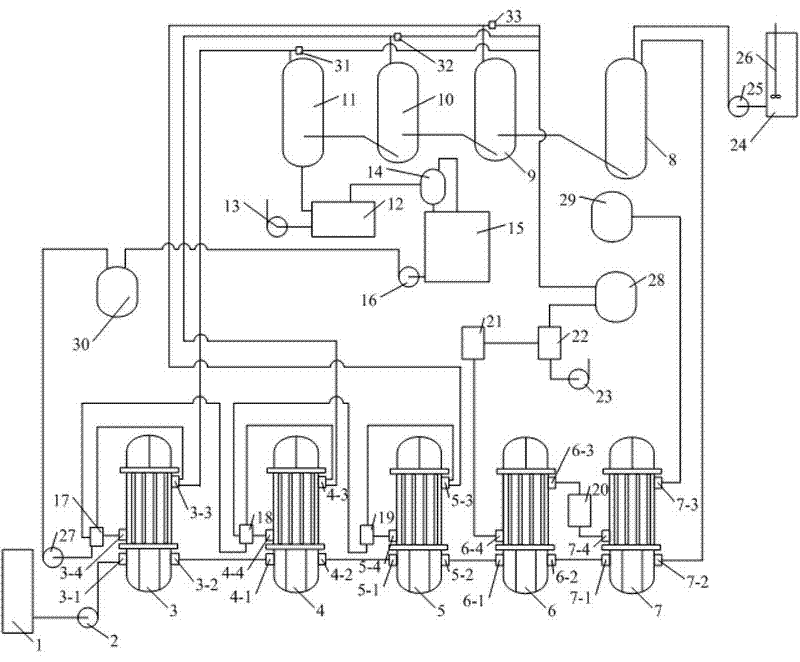

[0042] The structure of the dissolution system of gibbsite-type bauxite is as follows: figure 1 As shown, it includes a circulating mother liquor tank 1, a tube heating device, an insulation retention tank 8, a flash evaporation device and a dilution device;

[0043] The tube heating device consists of a first-level tube preheater 3, a second-level tube preheater 4, a third-level tube preheater 5, a condensate water tube heater 6 and a fresh steam tube heater 7 in series. , each tube preheater and tube heater are equipped with a medium inlet, a medium outlet, a material inlet and a material outlet;

[0044] The flash device is composed of a primary flash evaporator 9, a secondary flash evaporator 10 and a tertiary flash evaporator 11 in series; each flash evaporator is provided with a feed inlet, a material outlet and a gas outlet;

[0045] The insulation retention tank 8 is provided with a mother liquid feed port, a slurry feed port and a discharge port;

[0046] Circulatin...

Embodiment 2

[0066] The column tube of gibbsite type bauxite adds the stripping system structure of retention tank with embodiment 1;

[0067] The column tube of gibbsite type bauxite adds the stripping method of retention tank with embodiment 1, difference is:

[0068] (1) The temperature of the circulating mother liquor is 185°C after being heated by the new steam tube heater, and then enters the insulation retention tank;

[0069] (2) The desiliconized pulp in the desiliconized tank is transported to the heat preservation tank through the dissolution feeding pump. The temperature of the desiliconized pulp is 103°C. The desiliconized pulp is mixed with the circulating mother liquor for dissolution. The mixing amount is based on the temperature of the mixed material At 155°C, the dissolution time is 40 minutes;

[0070] (3) After the circulating mother liquor enters the three-stage tube preheater, it is heated to 120°C; after entering the condensate tube heater, it is heated to 125°C;

...

Embodiment 3

[0074] The column tube of gibbsite type bauxite adds the stripping system structure of retention tank with embodiment 1;

[0075] The column tube of gibbsite type bauxite adds the stripping method of retention tank with embodiment 1, difference is:

[0076] (1) The temperature of the circulating mother liquor is 190°C after being heated by the new steam tube heater, and then enters the insulation retention tank;

[0077] (2) Transport the desiliconized pulp in the desiliconized tank to the heat preservation tank through the dissolution feeding pump. The temperature of the desiliconized pulp is 105°C. The desiliconized pulp is mixed with the circulating mother liquor for dissolution. The mixing amount is based on the temperature of the mixed material At 160°C, the dissolution time is 30 minutes;

[0078] (3) After the circulating mother liquor enters the three-stage tube preheater, it is heated to 115°C; after entering the condensate tube heater, it is heated to 120°C;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com