Hot water pure water coproduction device by solar energy

A solar hot water and pure water technology, applied in solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve the problems of high temperature scaling, low water production rate, short life, etc., and solve the problem of drinking water in households , less auxiliary power consumption, less fouling tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

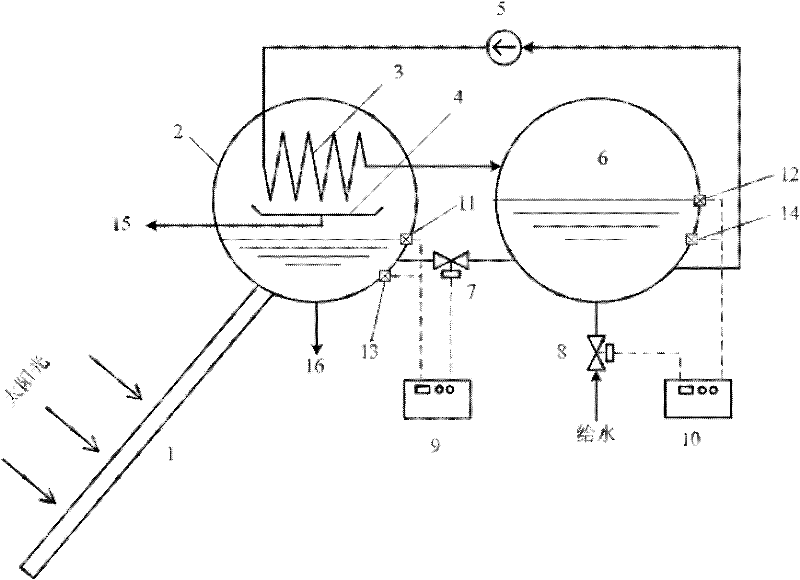

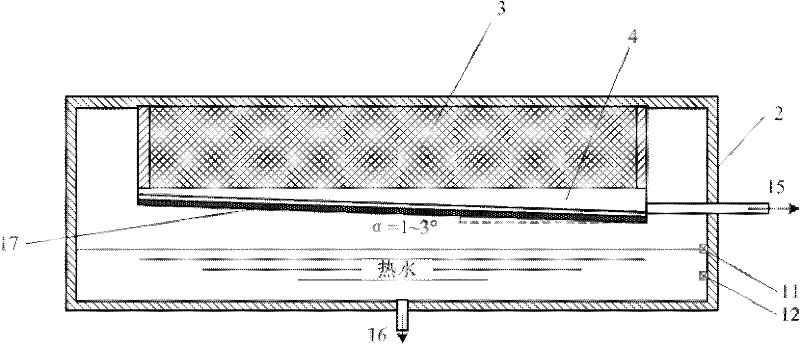

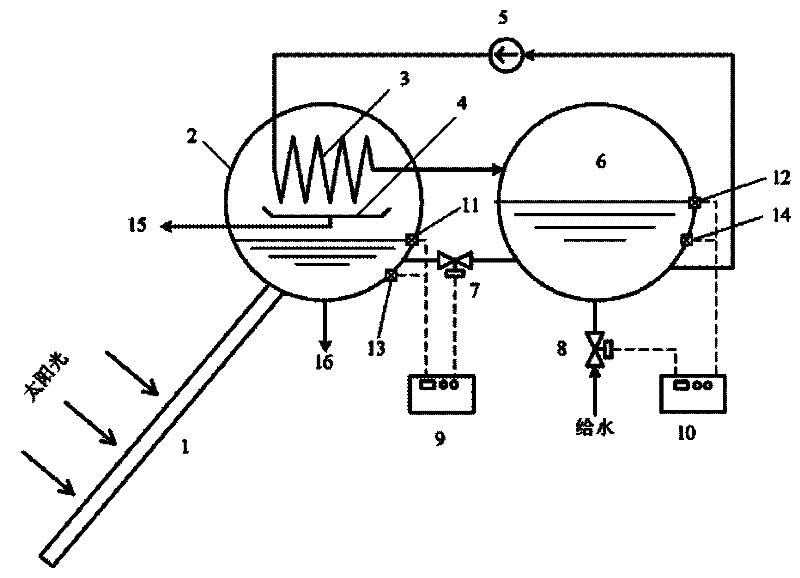

[0014] Such as figure 1 The shown solar hot water pure water cogeneration device consists of a vacuum tube collector 1, a hot water tank 2, a condenser 3, a water tray 4, a circulating water pump 5, a cooling water tank 6, an electric valve 7-8, and a water level controller 9-10, water level sensors 11-12 and pipelines. The condenser 3 is installed inside the hot water tank 2, and keeps a distance of more than 5 cm from the water level inside the hot water tank 2. The condenser is a finned tube heat exchanger with a spacing of 1.5 to 3 cm; the water receiving tray 4 is installed in the condenser At the bottom of the tank 3, the water receiving tray 4 is installed at a slight inclination along the length of the hot water tank 2, with an inclination angle of 1-3°. The bottom surface of the water receiving tray 4 is heat-insulated by polyurethane foam. The water pipe 15 lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com