Water ozonization treatment method by taking cerium oxide nanomaterial as catalyst

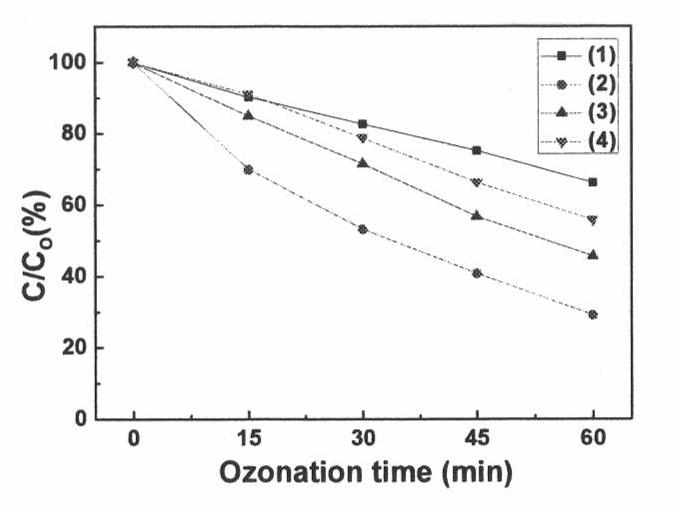

A nanomaterial, ozonated water technology, applied in oxidation water/sewage treatment, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It is not easy to purify and other problems, and achieves the effect of improved mineralization, simple operation and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

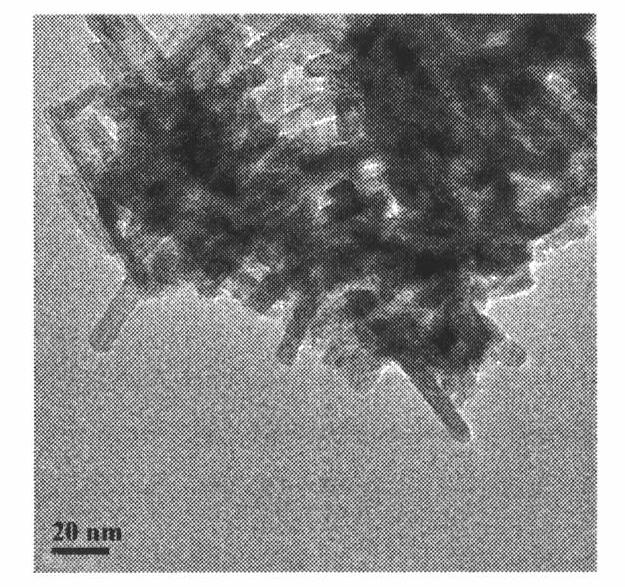

[0021] Weigh 4.50g of cerium chloride heptahydrate and dissolve it in 120ml of distilled water. After the solution is evenly mixed, quickly add 12g of solid sodium hydroxide while vigorously stirring. The resulting light purple solution was transferred to a polytetrafluoroethylene-lined reactor, and kept sealed at 130°C for 18 hours; after the reaction was completed, it was naturally cooled to room temperature, the resulting precipitate was washed with deionized water, dried at room temperature, and then calcined at 300°C 4h, to obtain cerium oxide nanomaterials. Its TEM photo is shown in Figure 1(a), and its XRD pattern is shown in figure 2 (a).

Embodiment 2

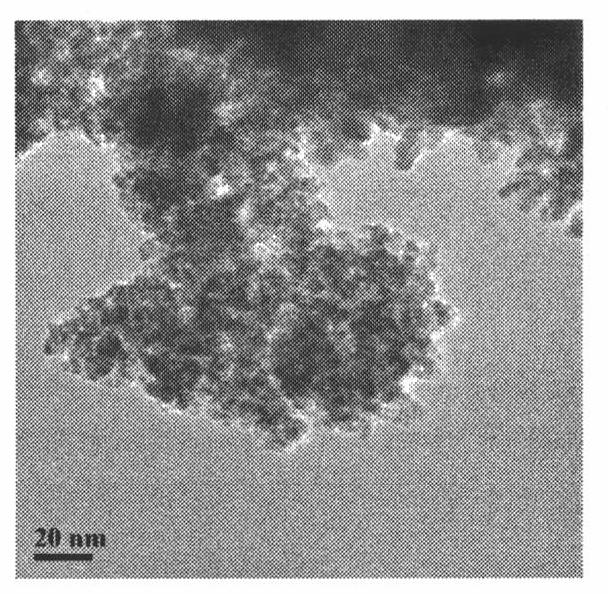

[0023] Weigh 5.22g of cerium chloride heptahydrate and dissolve it in 120ml of distilled water. After the solution is evenly mixed, quickly add 12g of solid sodium hydroxide while vigorously stirring. The resulting light purple solution was transferred to a polytetrafluoroethylene-lined reactor, and kept sealed at 130°C for 18 hours; after the reaction was completed, it was naturally cooled to room temperature, the resulting precipitate was washed with deionized water, dried at room temperature, and then calcined at 300°C 4h, to obtain cerium oxide nanomaterials. Its TEM photo is shown in Figure 1(b), and its XRD pattern is shown in figure 2 (b).

Embodiment 3

[0025] Weigh 4.50g of cerium chloride heptahydrate and dissolve it in 120ml of distilled water. After the solution is evenly mixed, quickly add 12g of solid sodium hydroxide while vigorously stirring. The obtained light purple solution was transferred to a polytetrafluoroethylene-lined reaction kettle, and kept sealed at 100°C for 18 hours; after the reaction was completed, it was naturally cooled to room temperature, the obtained precipitate was washed with deionized water, dried at room temperature, and then calcined at 300°C 4h, to obtain cerium oxide nanomaterials. Its TEM photo is shown in Figure 1(c), and its XRD pattern is shown in figure 2 (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com