Novel ultraviolet-cured resin having triazine ring and preparation method thereof

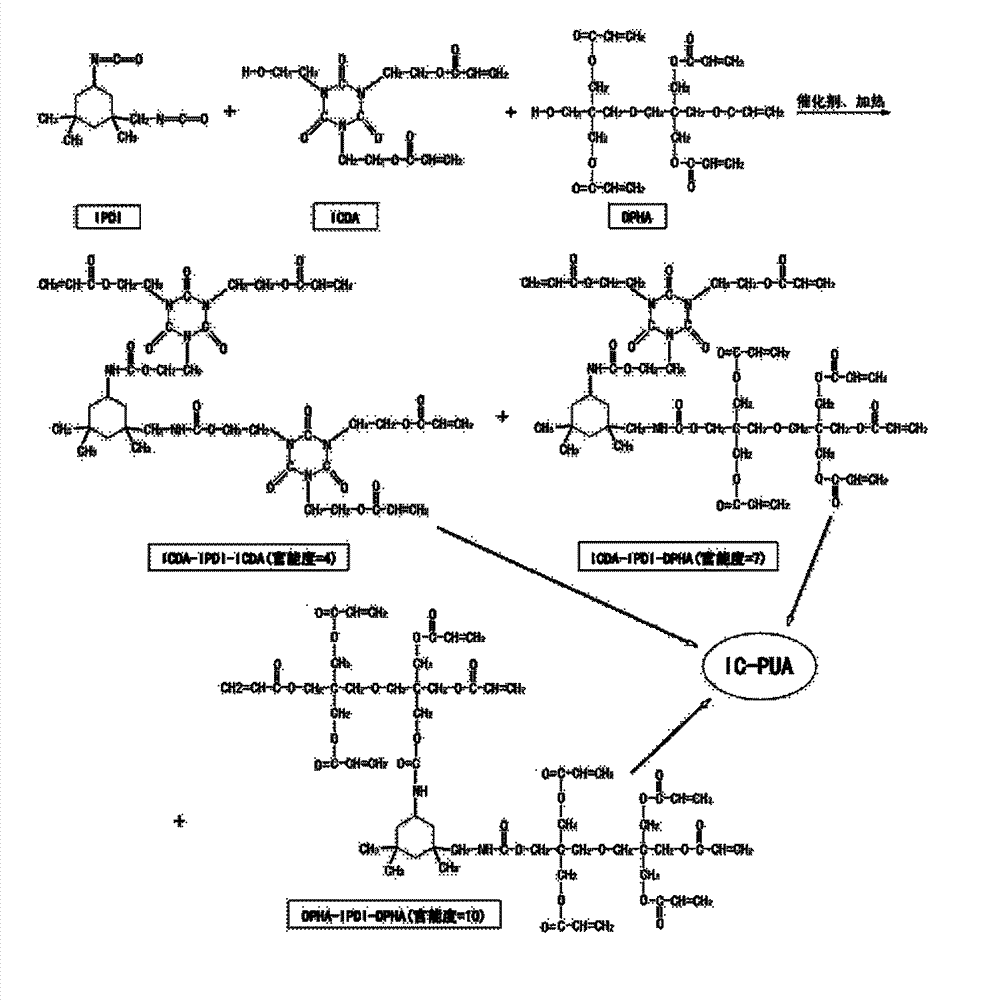

A technology for curing resins and triazine rings, which is applied in the field of new UV-curable resins containing triazine rings and its preparation, which can solve the problems of poor weather resistance and yellowing, insufficient hardness and flexibility, and high price of finished coatings And other problems, to achieve the effect of high hardness, good heat resistance, low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. In a clean and dry reaction kettle, put 180 kg of difunctional isocyanurate acrylate (ICDA) containing triazine ring, 150 kg of pentaerythritol triacrylate (PETA), and polyhexyl dipentaerythritol pentaacrylate in sequence. (DPHA) 200 kg, p-methoxyphenol 0.6 kg, stannous octoate 0.1 kg and butyl acetate 80 kg, then slowly raise the temperature to 60°C in about 1 hour;

[0032] 2. Put 100 kg of isophorone diisocyanate (IPDI) into a clean and dry high-level tank, and put it into the reaction kettle at a constant speed for 1 hour, during which the temperature is controlled at 55°C;

[0033] 3. After the dropwise addition is completed, keep warm for 1 hour, then raise the temperature to 90°C for 0.5 hours, and keep warm for 3 hours;

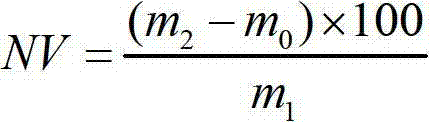

[0034] 4. Sampling test, when the isocyanate content (NCO%) is less than 0.5%, and the viscosity is 100mPa·s / 25℃, then react at constant temperature for 3 hours;

[0035] 5. Add 100 kg of hexahydrophthalimide hydroxyethyl acrylate (HHPIEA),...

Embodiment 2

[0039] 1. In a clean and dry reaction kettle, put 150 kg of difunctional isocyanurate acrylate (ICDA) containing triazine ring, 200 kg of pentaerythritol triacrylate (PETA), polyhexyl dipentaerythritol pentaacrylate (DPHA) 180 kg, hydroquinone 0.7 kg, dibutyltin dilaurate 0.08 kg and butyl acetate 70 kg, then slowly raise the temperature to 55°C in about 1 hour;

[0040] 2. Put 90 kg of isophorone diisocyanate (IPDI) into a clean and dry high-level tank, and put it into the reaction kettle at a constant speed for 2 hours, during which the temperature is controlled at 55°C;

[0041] 3. After the dropwise addition is completed, keep warm for another 2 hours, then raise the temperature to 80°C for 0.5 hours, and keep warm for another 5 hours;

[0042] 4. Sampling test, when the isocyanate content (NCO%) is less than 0.5%, and the viscosity is 100mPa·s / 25℃, then react at constant temperature for 3 hours;

[0043] 5. Add 100 kg of hexahydrophthalimide hydroxyethyl acrylate (HHPIEA...

Embodiment 3

[0047] 1. In a clean and dry reaction kettle, put 220 kg of difunctional isocyanurate acrylate (ICDA) containing triazine ring, 200 kg of pentaerythritol triacrylate (PETA), and polyhexyl dipentaerythritol pentaacrylate in sequence. (DPHA) 230 kg, copper sulfate 0.8 kg, stannous octoate 0.12 kg and butyl acetate 80 kg, then slowly raise the temperature to 50°C in about 1 hour;

[0048] 2. Put 100 kg of isophorone diisocyanate (IPDI) into a clean and dry high-level tank, and put it into the reaction kettle at a constant speed for 1.5 hours, during which the temperature is controlled at 58°C;

[0049] 3. After the dropwise addition is completed, keep warm for 1-2 hours, then raise the temperature to 86°C for 0.5 hours, and keep warm for 4 hours;

[0050] 4. Sampling test, when the isocyanate content (NCO%) is less than 0.5%, and the viscosity is 150mPa·s / 25℃, then react at constant temperature for 3 hours;

[0051] 5. Add 120 kg of hexahydrophthalimide hydroxyethyl acrylate (HH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com