Online detecting method and device for air leakage quantity of vacuum system of turbo generator unit

A technology for turbogenerator sets and vacuum systems, applied in measuring devices, using liquid/vacuum degree for liquid tightness measurement, measuring capacity, etc., can solve the problems of unfavorable unit safety, increase air solubility, vacuum drop, etc., and achieve measurement Simple mechanism, clear measurement principle and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

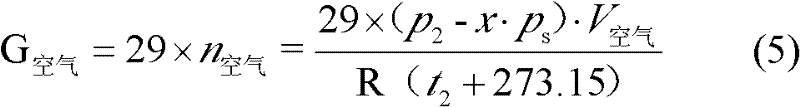

[0067] Parameters obtained by online measurement: temperature t 2 : 35°C, pressure p 2 : 106kpa, relative humidity: 50%, gas velocity: 1.5m / s, the pipe diameter of the exhaust pipe is 0.05m, and the cross-sectional area S=3.14×0.05 2 =0.0079m 2 ,

[0068] From formula (6) get V 空气 =V 湿空气 =v×S=1.5m / s×0.0079m 2 =0.0119m 3 / s,

[0069] From the saturated steam chart, the saturated steam pressure p at 35°C s It is: 5.626kpa. Substitute the above measured and calculated parameters into formula (5):

[0070] G 空气 =29×(106kpa-50%×5.626kpa)×0.0119m 3 / s÷[8.314J / (mol·K)×(35+273.15)]=0.0139kg / s=0.0139×3600kg / h=50.0378kg / h

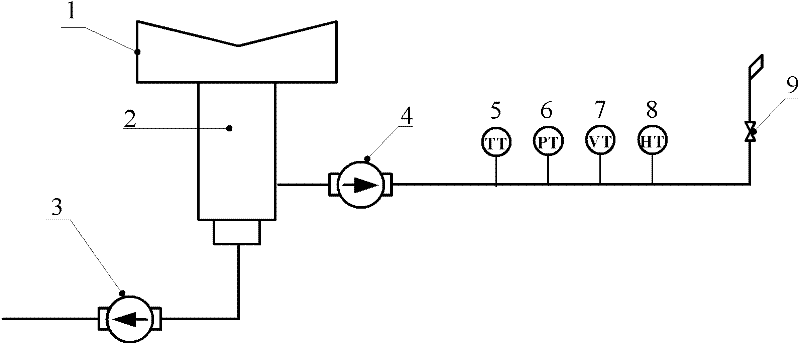

[0071] figure 2 Shown is an on-line detection device for air leakage of a vacuum system of a turbogenerator set provided by the present invention, which is connected to a water ring vacuum pump 4 on the air pumping pipeline of the condenser 2, and the pipeline behind the water ring vacuum pump is sequentially A temperature sensor 5, a pressure sensor 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com