X-ray on-line detection probe of steel wire rope core conveyor belt and signal acquisition and processing method

A technology for wire rope core and signal acquisition, applied in the field of non-destructive X-ray online detection equipment, can solve problems such as not being well implemented, poor reliability, and inability to accurately locate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing and example the present invention is described in further detail

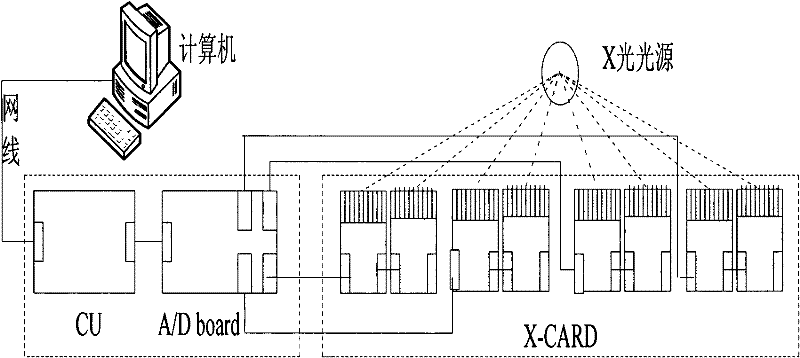

[0066] figure 1 It is a structural block diagram of the high-speed X-ray powerful conveyor belt detection system. The X-ray online detection detector of the steel wire rope conveyor belt of the present invention is the part inside the dotted line frame.

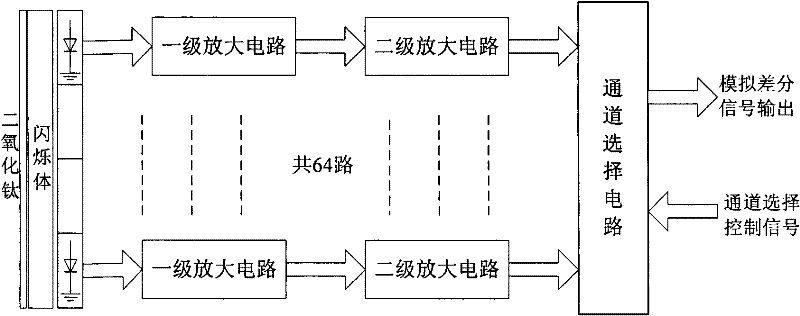

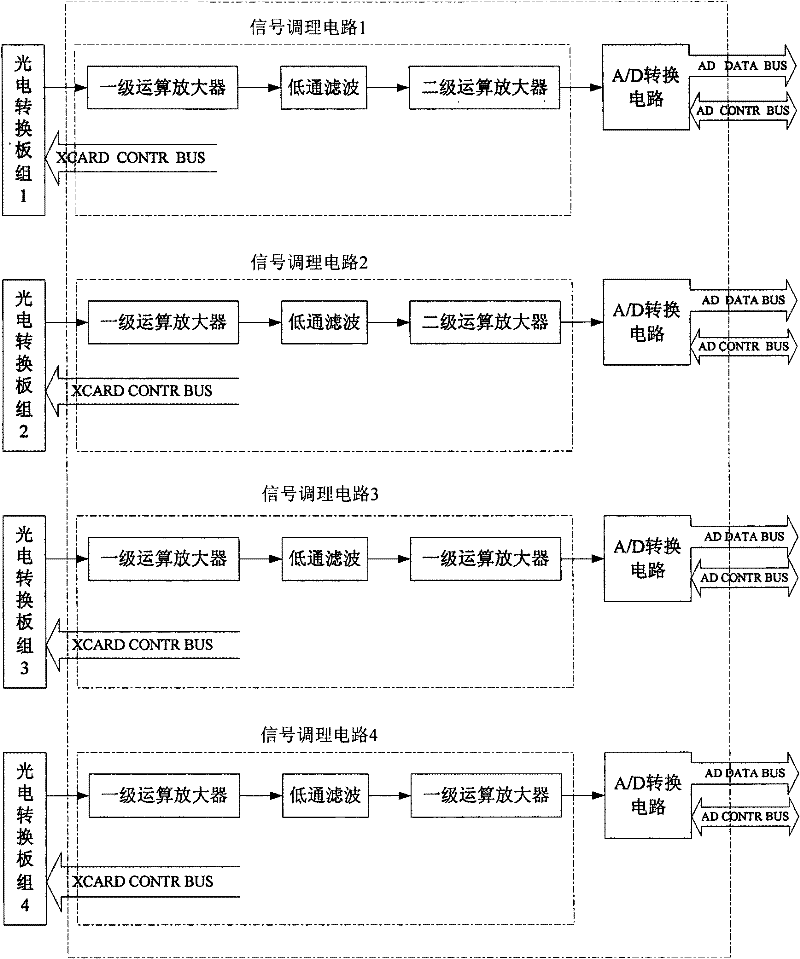

[0067] The X-rays generated by the X-ray generator pass through the running powerful conveyor belt and irradiate to the high-speed X-ray detector. High-speed X-ray detectors are used to receive, process and transmit X-rays passing through powerful conveyor belts. First, the silicon photodiode one-dimensional array of the photoelectric conversion module converts the projected image optical signal of the steel rope core in the strong conveyor belt into an electrical signal. Then the electrical signal is converted into a digital signal by analog signal conditioning and A / D conversion through the signal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com