Optical semiconductor device lead frame and manufacturing method thereof

A technology for optical semiconductor devices and manufacturing methods, which is applied to semiconductor devices, electrical solid-state devices, electrical components, etc., can solve problems such as reflectivity decline, brightness decline, and roughness influence, and achieves excellent long-term stability of reflectivity and reflection. The effect of good characteristics and excellent reflection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The substrates shown in Table 1 with a thickness of 0.3 mm and a width of 50 mm were subjected to the following pretreatment, and then subjected to the following electroplating treatment to obtain Inventive Examples 1 to 39, Conventional Example 1, and Comparative Example 1 having the configurations shown in Table 1. , 2 lead frames.

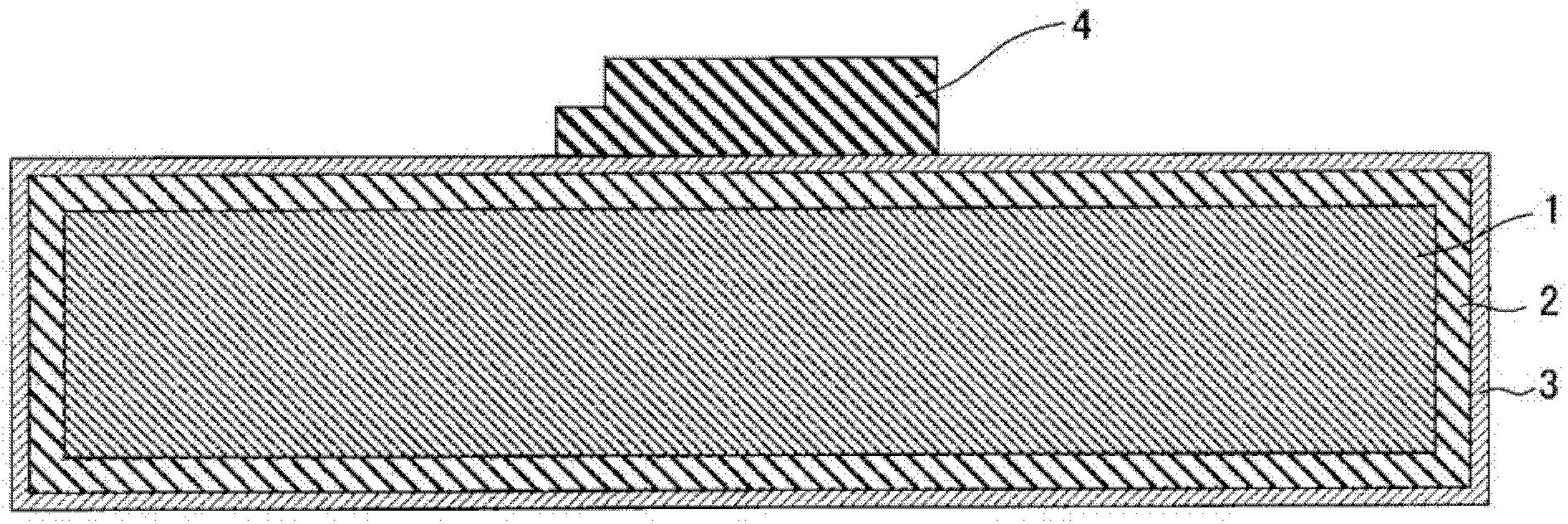

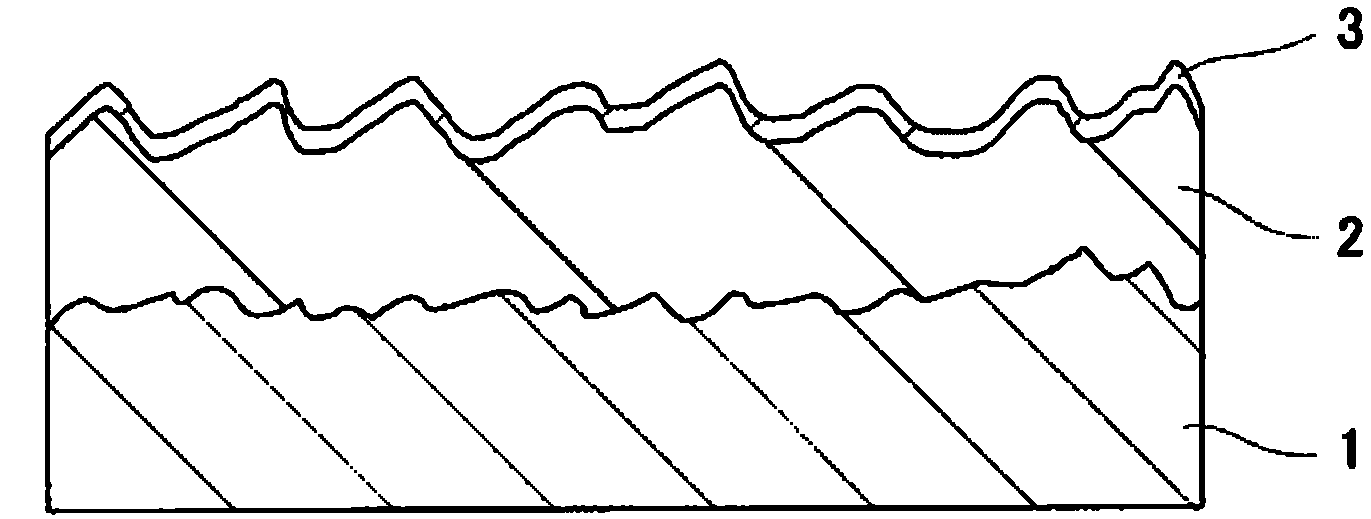

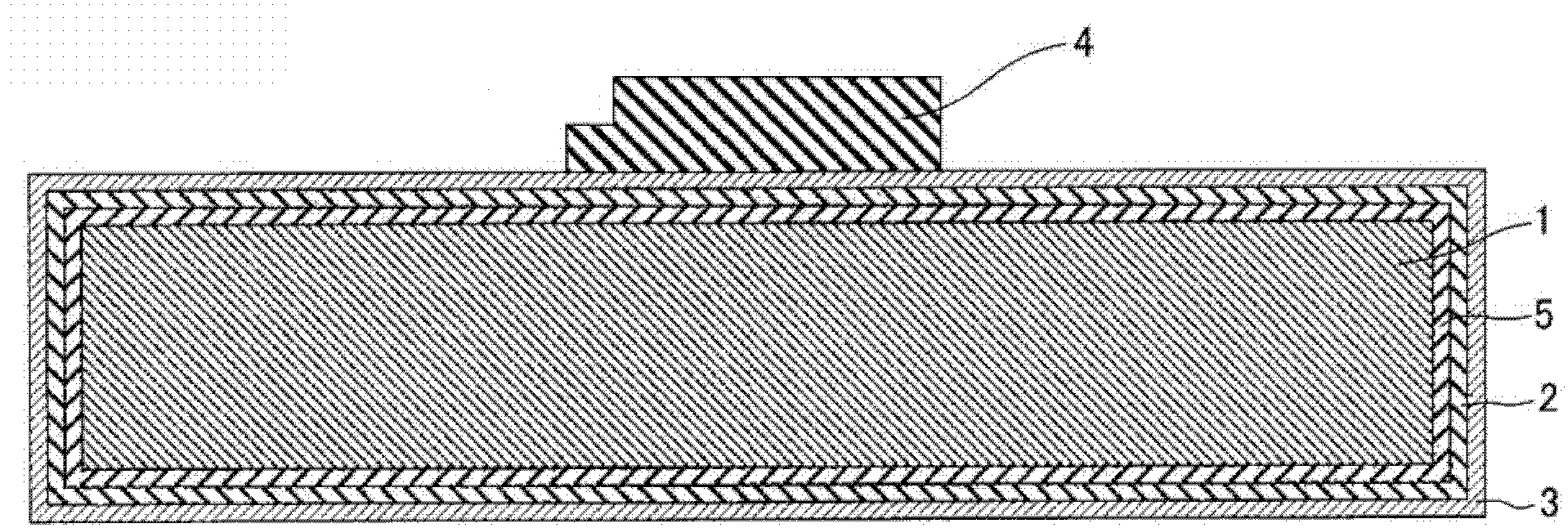

[0073] The layer structure of each lead frame is formed according to the order of substrate, pure silver layer and outermost film in Examples 1 to 6 of the present invention, and is formed according to the order of substrate, base layer and pure silver layer in prior example 1, the present invention In Examples 7 to 39 and Comparative Examples 1 and 2, the matrix, base layer, pure silver layer, and outermost film were formed in this order. In addition, the pure silver layer was formed to a thickness of 1 μm in all examples under the following Ag plating conditions, and before the outermost layer film was formed, it was measured by a conta...

Embodiment 2

[0158] On a copper alloy made of C19400 with a thickness of 0.15 mm and a width of 30 mm, a nickel plating layer was formed as a base layer with a thickness of 1.0 μm, a pure silver layer was formed on top of it, and the thickness shown in Table 3 was formed as the outermost layer The Pt electroplated layer of the present invention obtained the lead frames of Examples 40-63 and Comparative Examples 3-7. Each plating step or the composition of the plating solution was the same as in Example 1, and glossy silver plating and matte silver plating were used for the formation of the pure silver layer. In addition, when adjusting the Ra and plating thickness of the pure silver layer, in glossy silver plating and matte silver plating, use 0.1-10A / dm 2 Conditions to adjust the current density. In addition, Ra of the pure silver layer was measured with a contact-type surface roughness meter (SURFCORDER SE-30H (trade name): manufactured by Kosaka Laboratories) in the same manner as in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com