A kind of cationic flotation collector and its preparation method

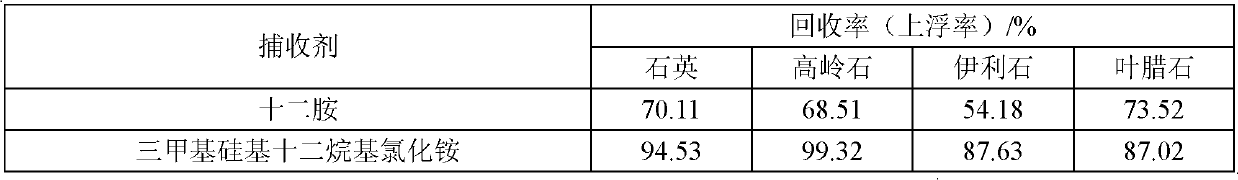

A cationic collector technology, which is applied in flotation, chemical instruments and methods, solid separation, etc., can solve the problems that have not been reported on the application of organosilicon ammonium salt compounds, achieve excellent flotation performance, and be easy to add and use , Strong harvesting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Heat 185 parts of dodecylamine to 30-40°C to melt into a liquid, slowly add 108.6 parts of trimethylchlorosilane under stirring, stir and react for 30 minutes, and obtain 293.5 parts of white powder product trimethylsilyl dodecyl ammonium chloride. The resulting product does not need to be refined and can be directly used as a flotation collector.

Embodiment 2

[0025] Heat 185 parts of dodecylamine to 30-40 ° C to melt into a liquid, slowly add 140.6 parts of methyl dimethoxychlorosilane in a molar ratio of 1:1, stir and react for 50 minutes, and obtain 325 parts of white powder product methyl Dimethoxysilyllauryl ammonium chloride. The resulting product does not need to be refined and can be directly used as a flotation collector.

Embodiment 3

[0027] Heat 269 parts of octadecylamine to 60°C to melt into a liquid, slowly add 108.6 parts of trimethylsilyl chloride under stirring, stir and react for 60 minutes, and obtain 369.8 parts of white powder product trimethylsilyl octadecyl chloride Ammonium. The resulting product does not need to be refined and can be directly used as a flotation collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com