A gelation and consolidation process of waste incineration fly ash

A technology for waste incineration fly ash and process, applied in the field of environmental engineering, can solve problems such as large differences, secondary pollution, and increased fly ash capacity, so as to promote sufficient mineralization reaction, promote sufficient mixing reaction, and ensure stability. effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

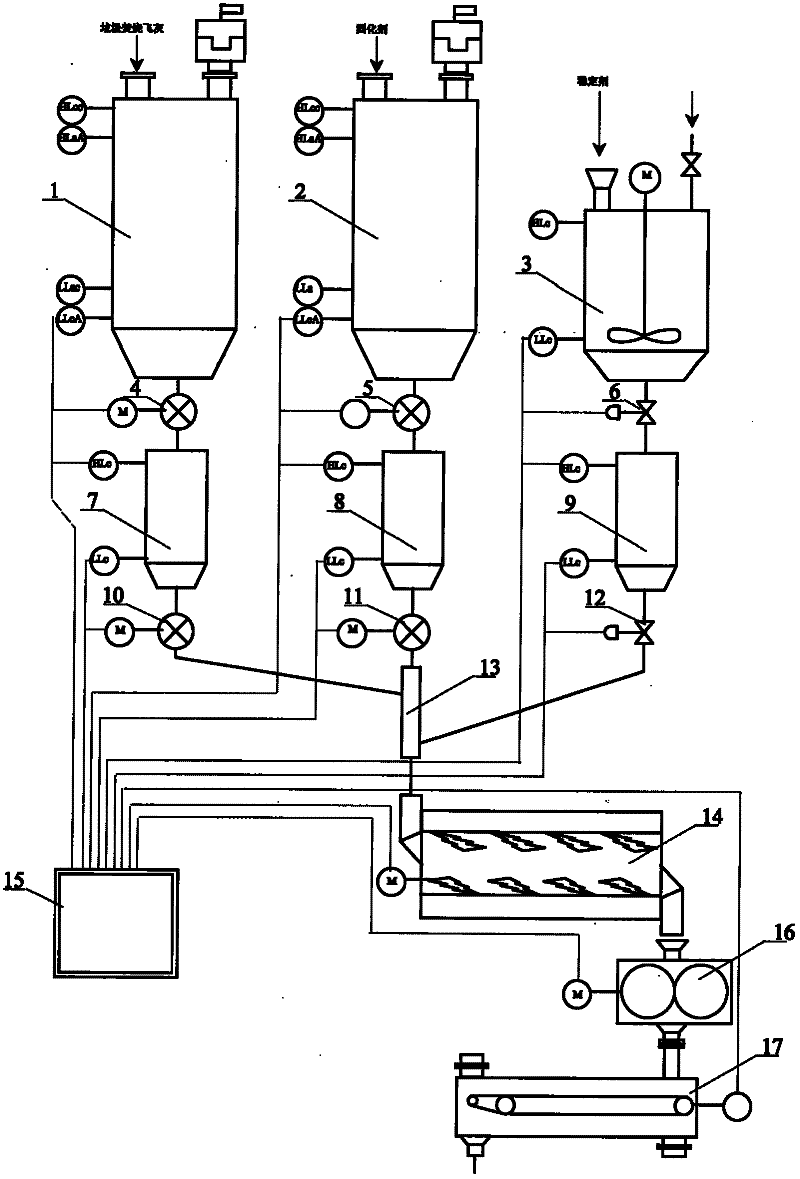

Method used

Image

Examples

Embodiment example

[0035] The following is a further detailed description in conjunction with relevant implementation cases:

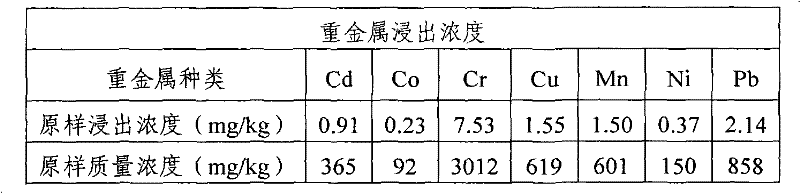

[0036] The heavy metal content of fly ash is shown in Table 1.

[0037] Table 1 Results of heavy metal leaching test of fly ash

[0038]

Embodiment example 1

[0040] Input the material parameters on the PLC console, and the radar material level control device and the PLC console will instruct the electric control valve to measure 300kg of fly ash and 45kg of cement. After the fly ash and cement are preliminarily mixed through the diverter valve, they enter the strong mixer and stir for 5 minutes. Put 0.6kg of amino strong basic heavy metal chelating resin and 90kg of water into the stabilizer storage bin and mix evenly to make a stabilizer solvent, then all the stabilizer solvent is added to a strong mixer through an atomizer and stirred for 25 minutes, and finally The mixed fly ash is extruded by a granulator, and the diameter of the small particles is 10mm-30mm. The formed fly ash particles are stored in a cool and dry curing room for 3-7 days, and the pellets are randomly selected according to the "Solid Waste Leaching The procedure in GB 5086.1-1997 to detect the leaching concentration of heavy metals in toxic leaching method fl...

Embodiment example 2

[0042]Input the material parameters on the PLC console, and the radar material level control device and the PLC console will instruct the electric control valve to measure 100kg of fly ash and 20kg of HAS curing agent. After the fly ash and HAS curing agent are preliminarily mixed through the diverter valve, they enter the strong mixer and stir for 5 minutes. Put 0.5kg of heavy metal chelating resin and 30kg of water into the stabilizer storage bin and mix evenly to make a stabilizer solvent, then add all the stabilizer solvent into a strong mixer through an atomizer and stir for 25 minutes, and finally mix the mixture The ash is extruded by a granulator, and the diameter of the small particles is 10mm to 30mm. The formed fly ash particles are stored in a cool and dry curing room for 3 to 7 days, and the small particles are randomly selected according to the "solid waste leaching and toxicity leaching method". Method "GB 5086.1-1997 and the procedures in the detection of its h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com