A kind of treatment method of high sulfate organic waste water

A technology for organic waste water and high sulfate content, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as troublesome operation and maintenance, large equipment investment, and difficulty in implementation. Achieve the effect of reducing the salinity requirement of influent water, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation process is as follows:

[0022] 1. Cooling crystallization, solid-liquid separation

[0023] SO in the wastewater 4 2- The content is about 212 000 mg / L, the COD concentration is about 18 000 mg / L, and the COD / SO 4 2- <0.1, the cooling crystallization process temperature is 3-6 ℃, and the cooling time is 4-6 h. Solid-liquid separation of sulfate crystals and sulfate wastewater is carried out, and the obtained salt is recycled. The wastewater is cooled and crystallized repeatedly until no crystals are precipitated. During the implementation of the invention, the number of cooling crystallization times was 2, and the sulfate content in the wastewater after cooling crystallization and solid-liquid separation treatment was reduced to about 96 000 mg / L, and the removal rate reached 54.7%.

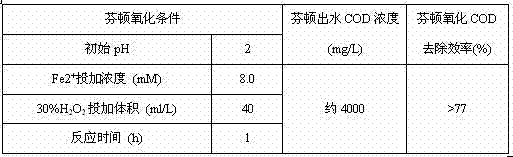

[0024] 2. Fenton oxidation

[0025] Cool down the crystallized wastewater, adjust the pH with sulfuric acid, and then add Fenton's reagent FeSO 4 · H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com