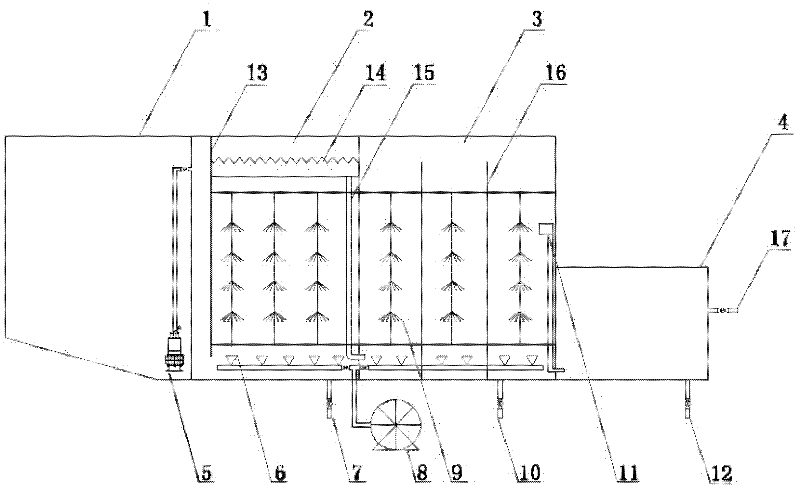

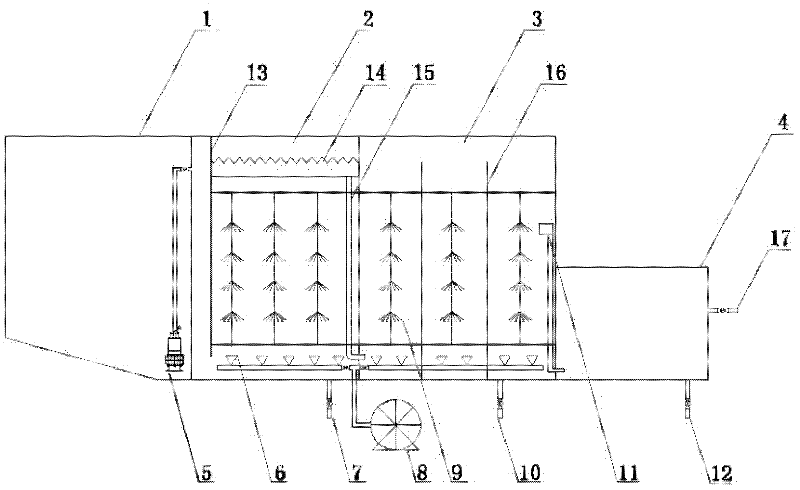

A biologically enhanced beer industry wastewater biological treatment device and method

An industrial wastewater and bioaugmentation technology, which is applied in food industry wastewater treatment, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problem of high energy consumption of contact oxidation, achieve high oxygen utilization rate, simple operation and management, and improve Effects of Processing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The waste water is introduced into the hydrolysis and acidification tank from the adjustment tank by the submersible sewage pump, and the waste water enters the main reaction zone of the hydrolysis and acidification tank from the bottom through the diversion wall. A small amount of aeration, control DO<0.5mg / L, pH 6-7, normal temperature, residence time 6h, improve the biodegradability of wastewater, use the mud outlet at the bottom to discharge mud regularly; The overflow weir and the diversion pipe of the hydrolysis acidification tank are the water inlet of the SBR reaction tank. The water inlet time is 0.5h. 7-8, normal temperature, the SBR reaction tank is equipped with elastic three-dimensional packing and aeration device, and ammonia nitrogen degrading bacteria are added. The reaction period is 6 hours, and the sludge discharge port at the bottom of the tank is regularly discharged; the effluent of the SBR reaction tank flows into the disinfection tan...

Embodiment 2

[0019] Embodiment 2: The waste water is introduced into the hydrolysis and acidification tank from the adjustment tank by the submersible sewage pump, and the waste water enters the main reaction zone of the hydrolysis and acidification tank from the bottom through the diversion wall. A small amount of aeration, control DO<0.5mg / L, pH 6-7, normal temperature, residence time 12h, improve the biodegradability of wastewater, use the mud outlet at the bottom to discharge mud regularly; The overflow weir and diversion pipe of the hydrolysis and acidification tank are the water inlet of the SBR reaction tank. The water inlet time is 1 hour. After the water inlet is completed, it is aerated for 8 hours, allowed to settle for 1 hour, decanted for 1 hour, and idle for 1 hour. The pH is controlled at 7-8. At room temperature, the SBR reaction tank is equipped with elastic three-dimensional fillers and aeration devices, and ammonia nitrogen degrading bacteria are added. The reaction perio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com